Last year I had the opportunity of learning textile screen printing, and found it to be one of those brilliant creative ways for enabling colour designs onto fabric. We will all go ahead to start learning this exciting craft together right here in a tutorial. At the end by means of this you will be having enough garment and other printings and in turn, get to know It is that easier for your ideas out from the head into visuals.

Textile screen printing is the method of using a mesh to press an ink-blocking stencil onto a fabric, which leaves behind any design you desire. This is something you can do yourself and all the tools you need are very simple, basic ones. So, let's break down ad show you what steps can YOU do for YOUR very own journey on textile screen printing!

Set the screen: Screen is one of the most important input to you. It comes with a special mesh that enables you to move the ink through this to your fabric. To have your screen prepared you need to coat them with a light sensitive gel. This is what gel operated when in light we bring to screen. When you use the gel, ensure that it dries completely. Follow it by your design clear film and lay on top of screen. Finally, light up the screen with a correct lighting that is secure for your eyesight.

Washing of Screen:- It is very useful in a situation when the screen has to be washed after exposure with light. Wash Away! This is an important step! The washing will remove the non-light-exposed parts, i.e. those that made up your image on screen.

Ink Time: The fun part. Place it on your cloth where you would like to design. So, I'll preface that this tutorial does assume you know what silk screening is- if not generally it's just putting some ink on a screen and using/holding some of these squeegee things to force the ink met through mesh. This results in your printing design on the fabric. Repeat these steps if you want to see the more colors or layers, and complete your design!

This is not a craft that you can do — but an art! Textile screen printing This one is chosen by all the most talented designers for designing some of the best designs that people admire. In this article, I will try to focus on some basic tips useful in screening textile and fun with it.

Texture: Once you have the concept of your design, bring in some texture to give it even more depth. This is done through the use of variably inks or choosing a textured screen. Having textures on your print work makes it more personalized and unidentifiable from the rest.

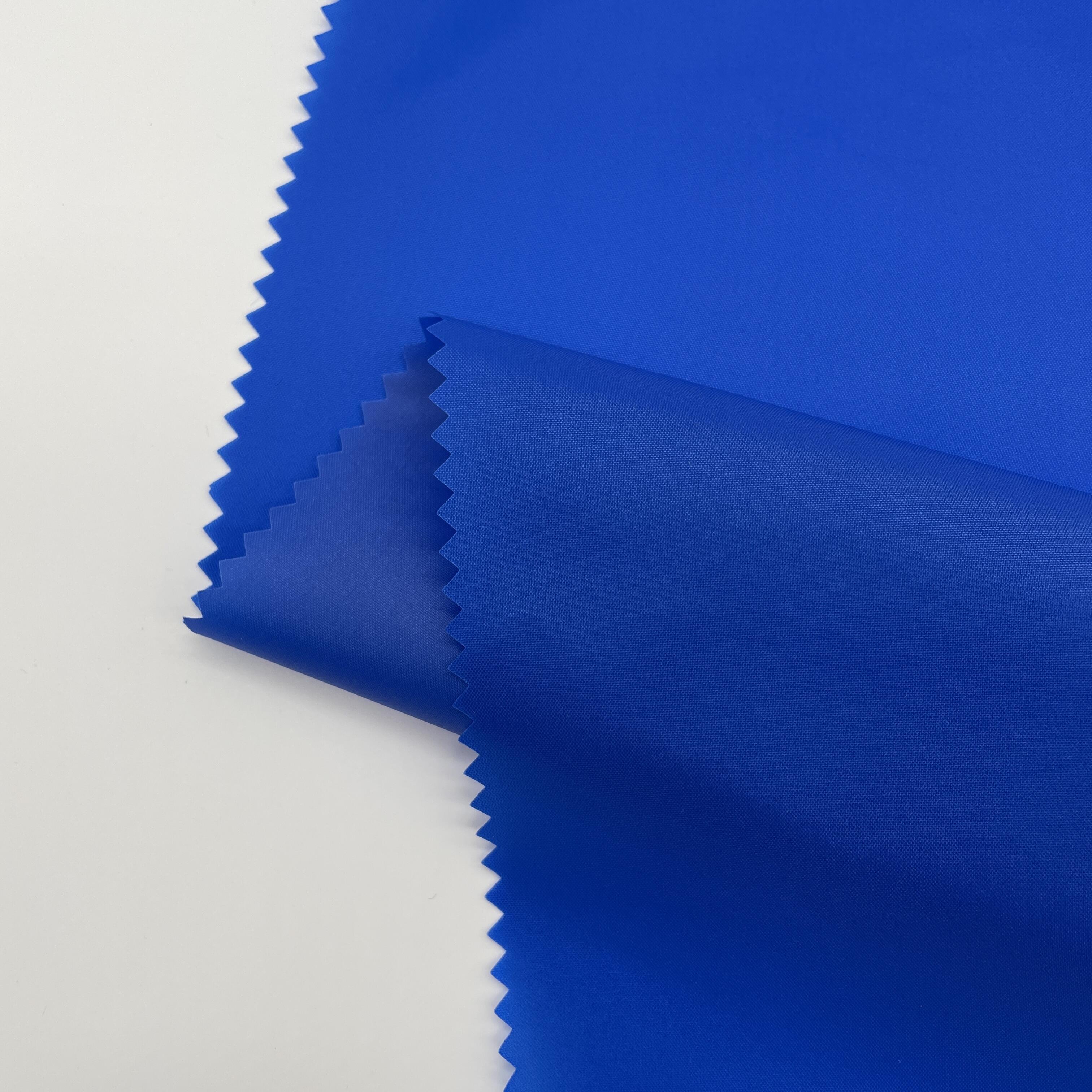

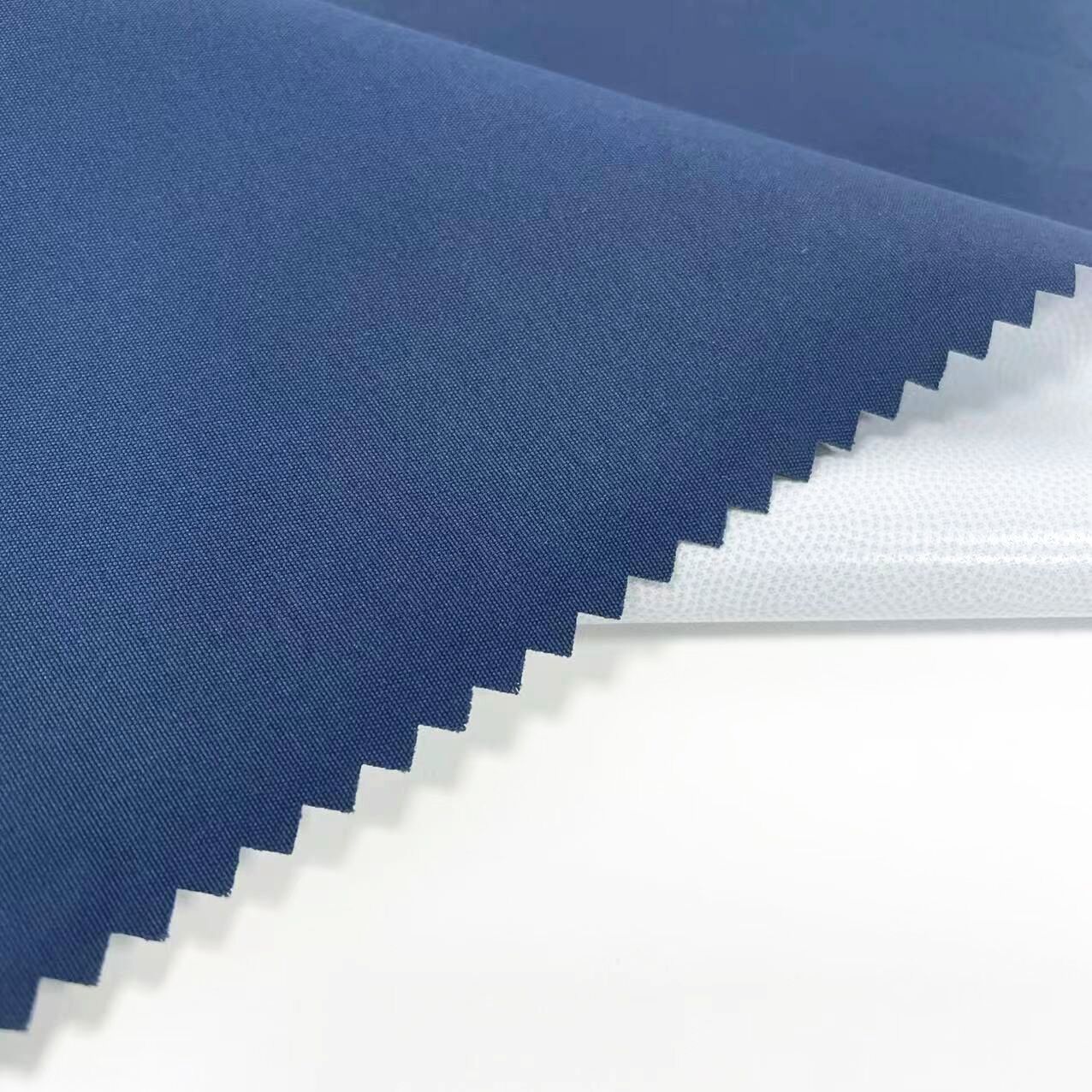

Suly Textile, a professional fabric producer with a total of textile screen printing, has four lines of PU coated lines. These PU coated lines are all imported and provide a better quality coating. We also have two PVC coating lines that make textiles for outdoor jackets, bags and tents, industrial uses and more. Our technician all have over 10 years working in the textile industry and can offer more quality-controlled service and solutions. Our nylon fabric is a strong product and we import from Taiwan dye and greige, and complete the finishing at our manufacturing facility.

The company is accredited through textile screen printing, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our local certified 3rd party testing center who can give us fast, exact and certified testing reports. Our sales staff can offer quick and accurate responses to customers' requests. However, if a client has difficult for shipping, we also have our own teams of shipping who can give good solutions to shipping.

Our company provides OEM service which can weave precisely to meet your needs such as Piece dyeing, textile screen printing water repellent, printing, Water column, Teflon finishing TPE coating, TPU coating Anti-static, Down proof, PU milky/clear layer and Flame retardant, High breathable black-out, PA Brushed, PVC lamination PU transfer, moisture absorbing and quick drying, etc. Our company also offers custom-made services, which allow us to weave in accordance with your specifications, including Crinkled dyeing and piece dyeing. We can also provide TPU/TPE coatings, antistatic, TPU milky/clear, flame retardant, high breathable black-out, PA and brushed laminations, PU transfer, etc.

Suly Textile offers a wide assortment of textiles that can be customized to meet the requirements of textile screen printing. The company is involved in the manufacturing and distribution of all kinds of chemical fabric and blended fabrics, including dyeing coatings, bonding and laminating. We are specialized in functional fabrics such as strong water repellent fabric and high water column fabric. We also provide anti-static, antiUV, moisture absorbing, quick drying, flame retardant, anti-heat, printed, and IFR fabrics. We also can accept printing using low MOQ. We have a variety of fabrics and provide a single-stop solution.