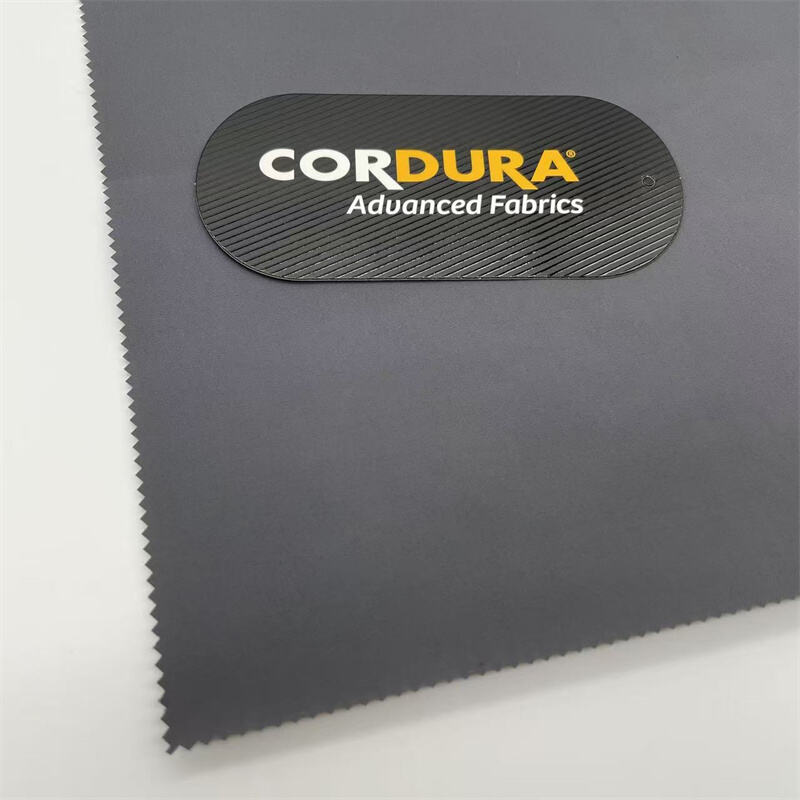

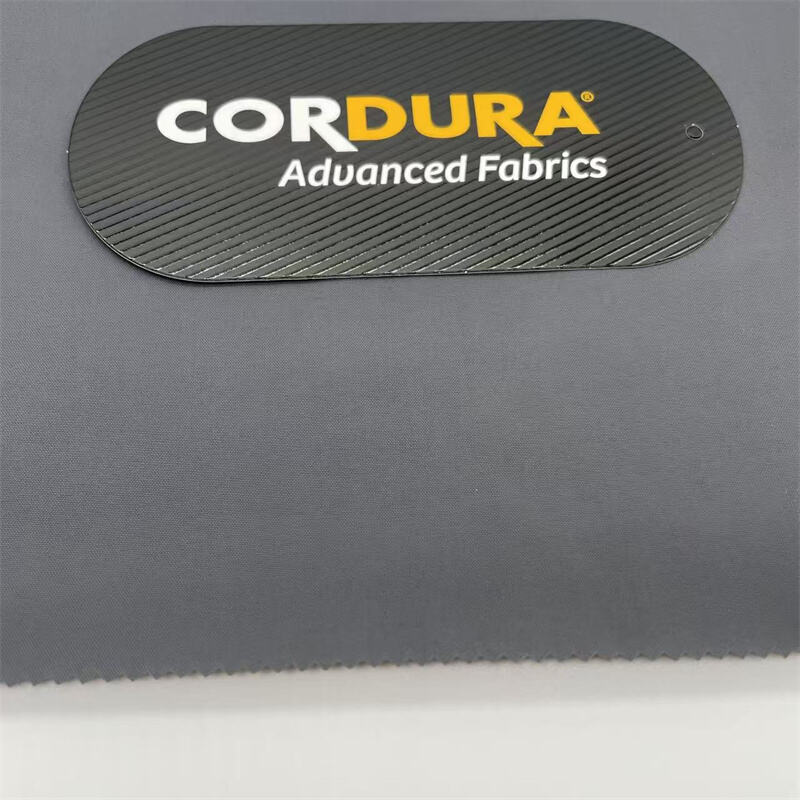

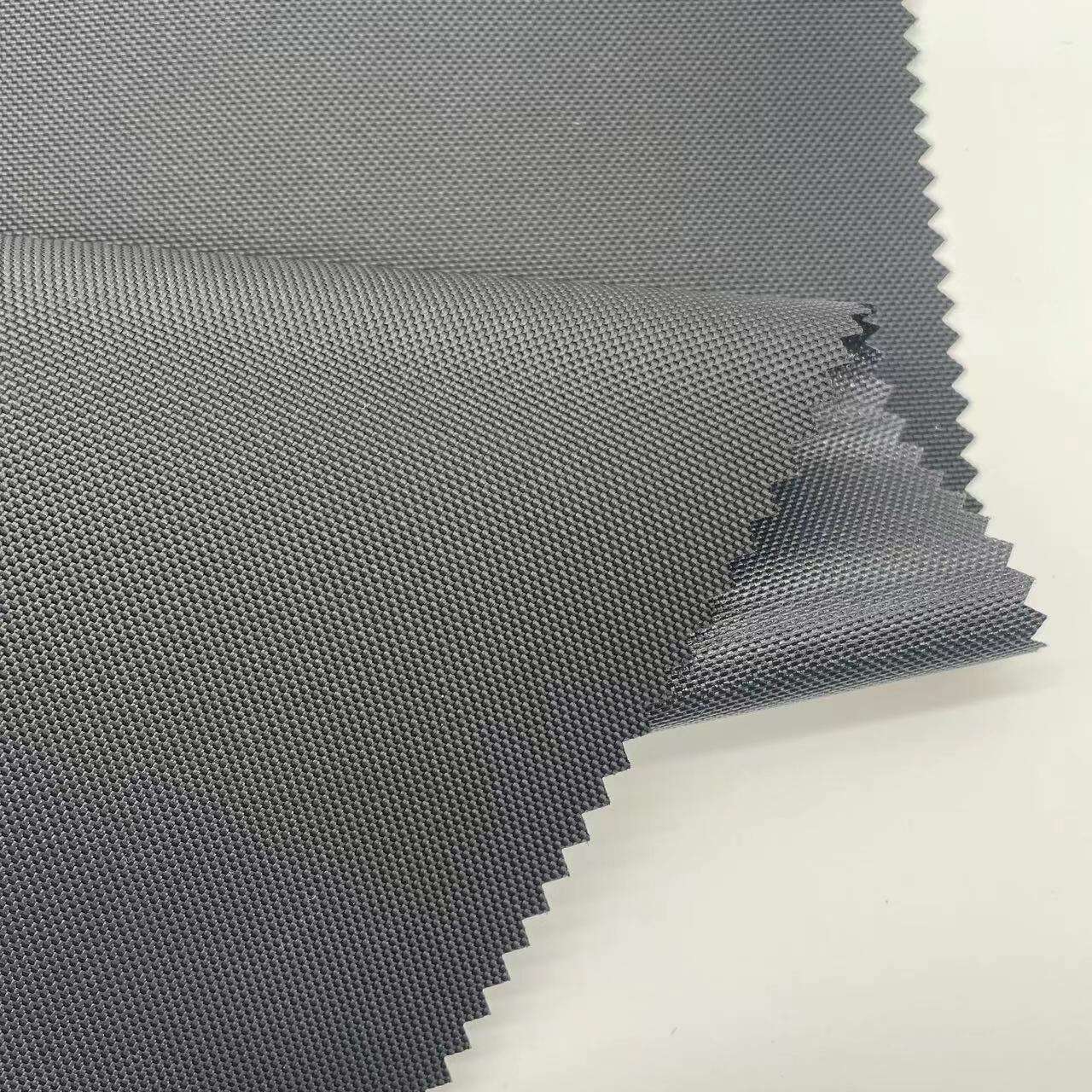

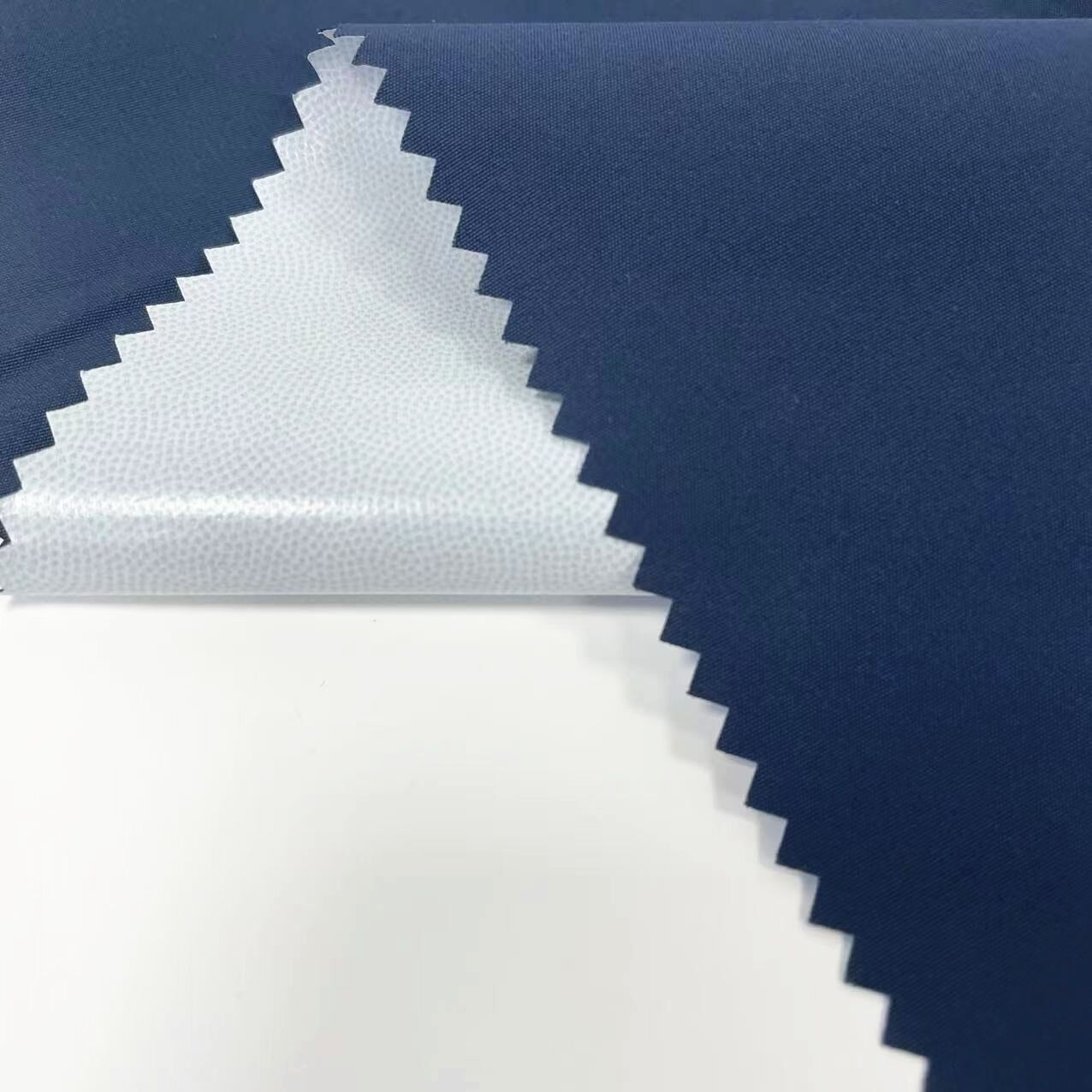

PFAS free Water repellent 80D nylon6.6 cordura fabric with 2 pass PU coating 7894FD

| Content: | Nylon |

| Coating: | PU(Polyurethane) |

| Country of origin: | US |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

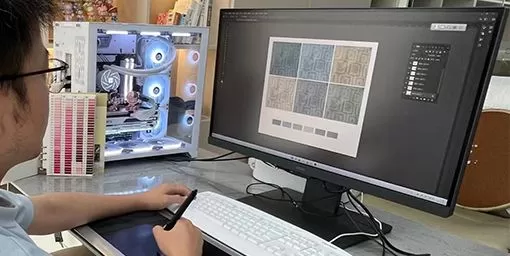

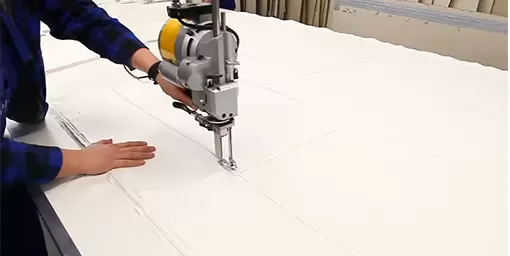

- Process flow

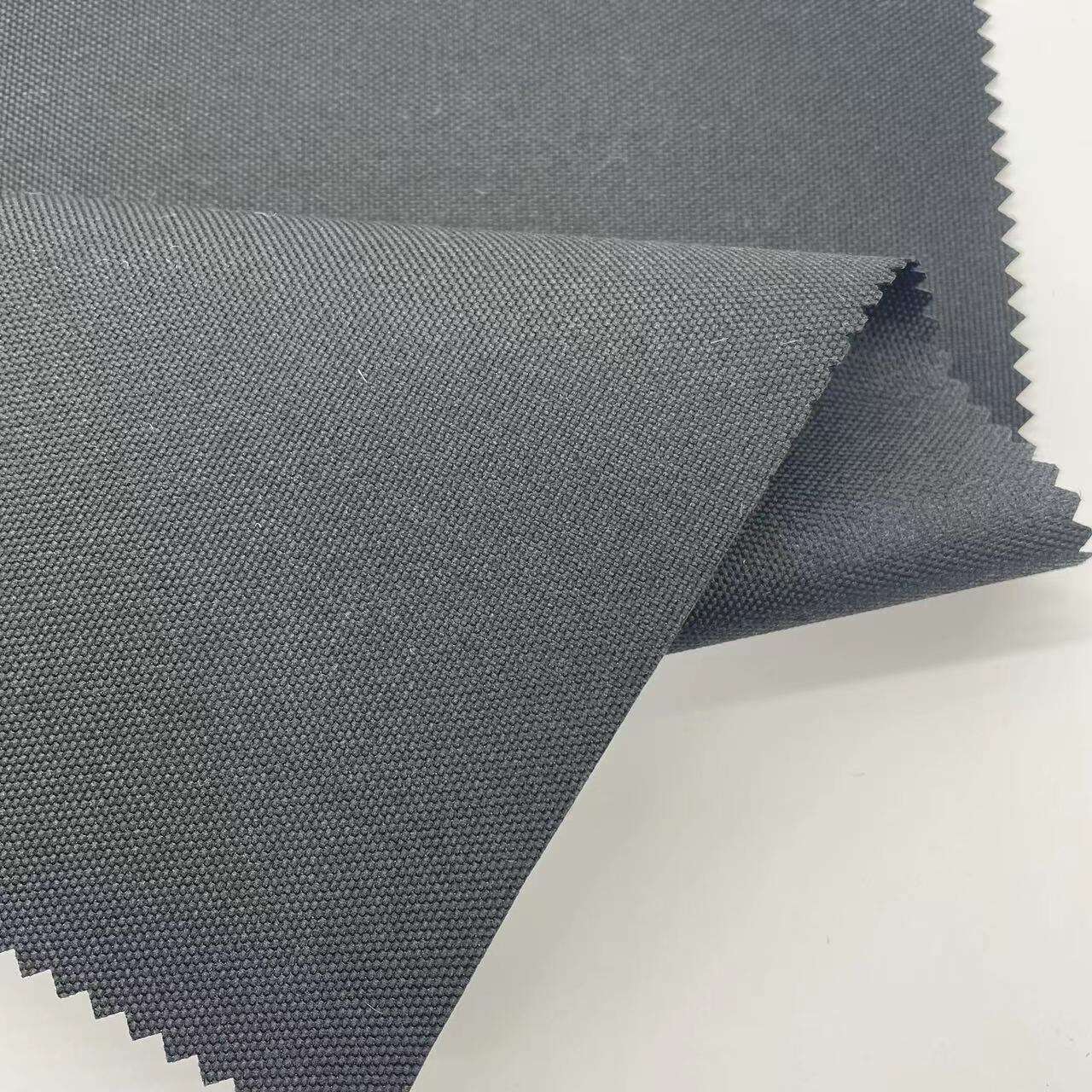

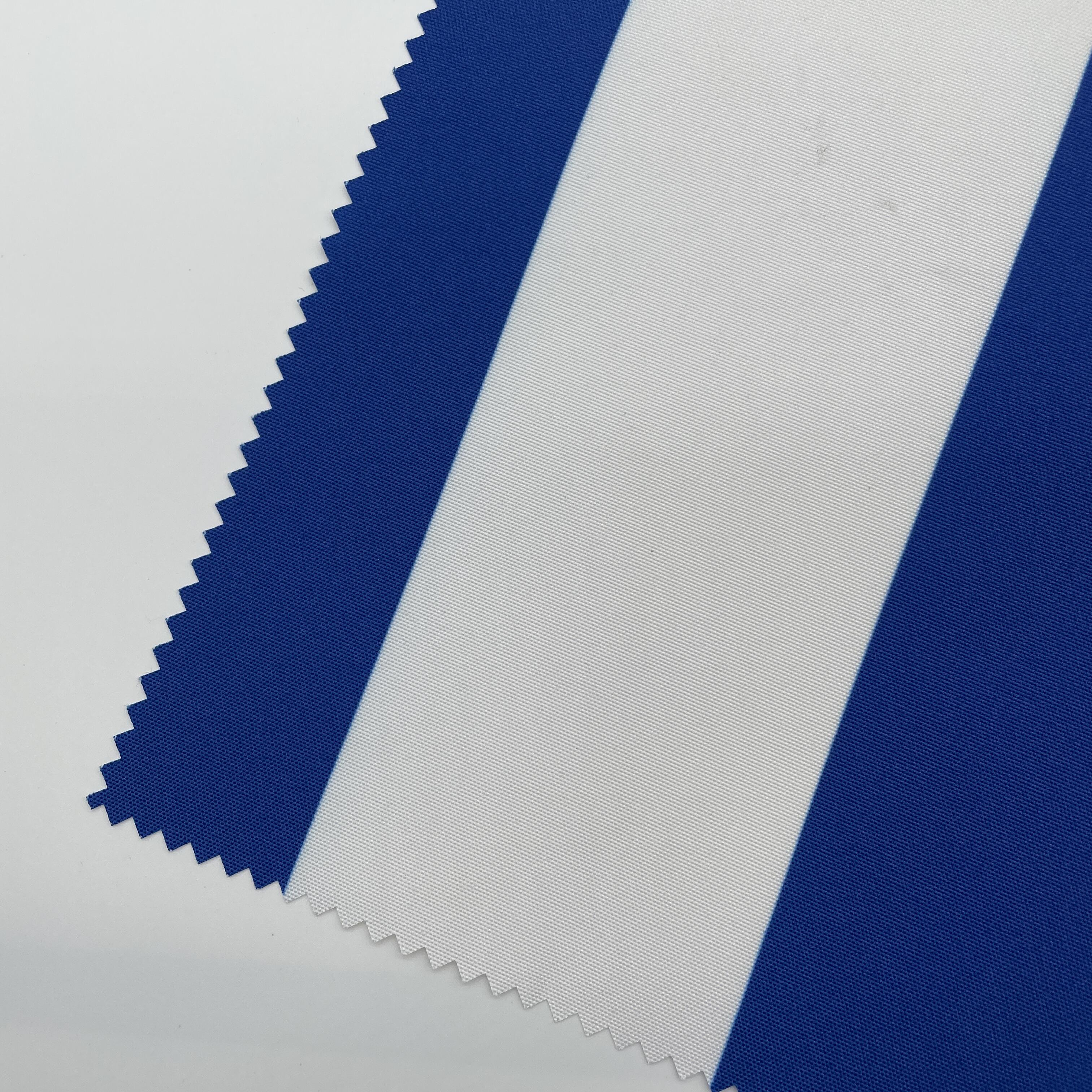

- Related products

- Inquiry

Parameter

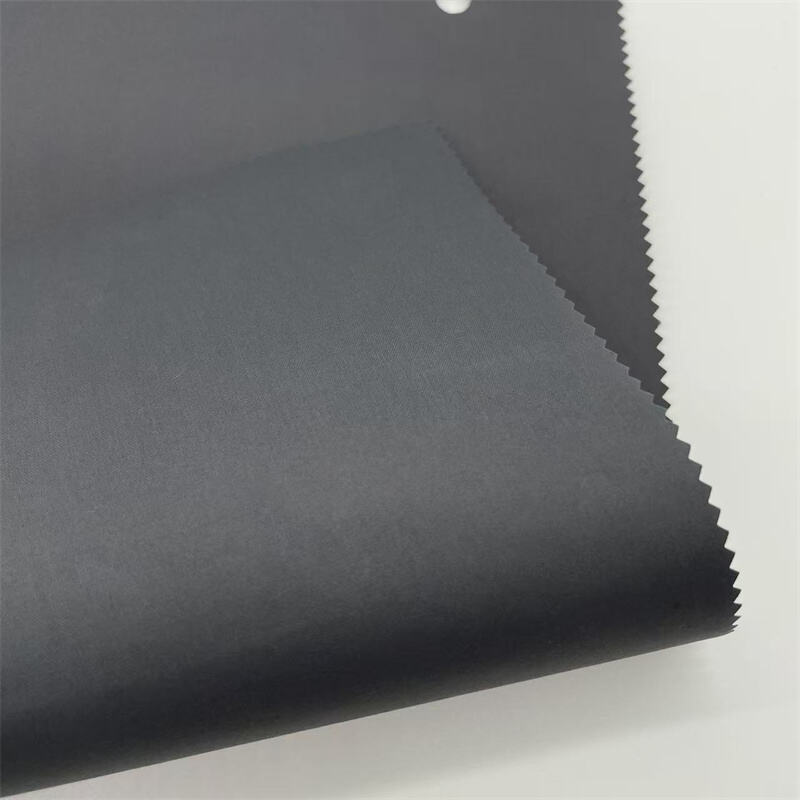

80D Nylon 6.6 Cordura® with 2-Pass PU Coating & Eco DWR

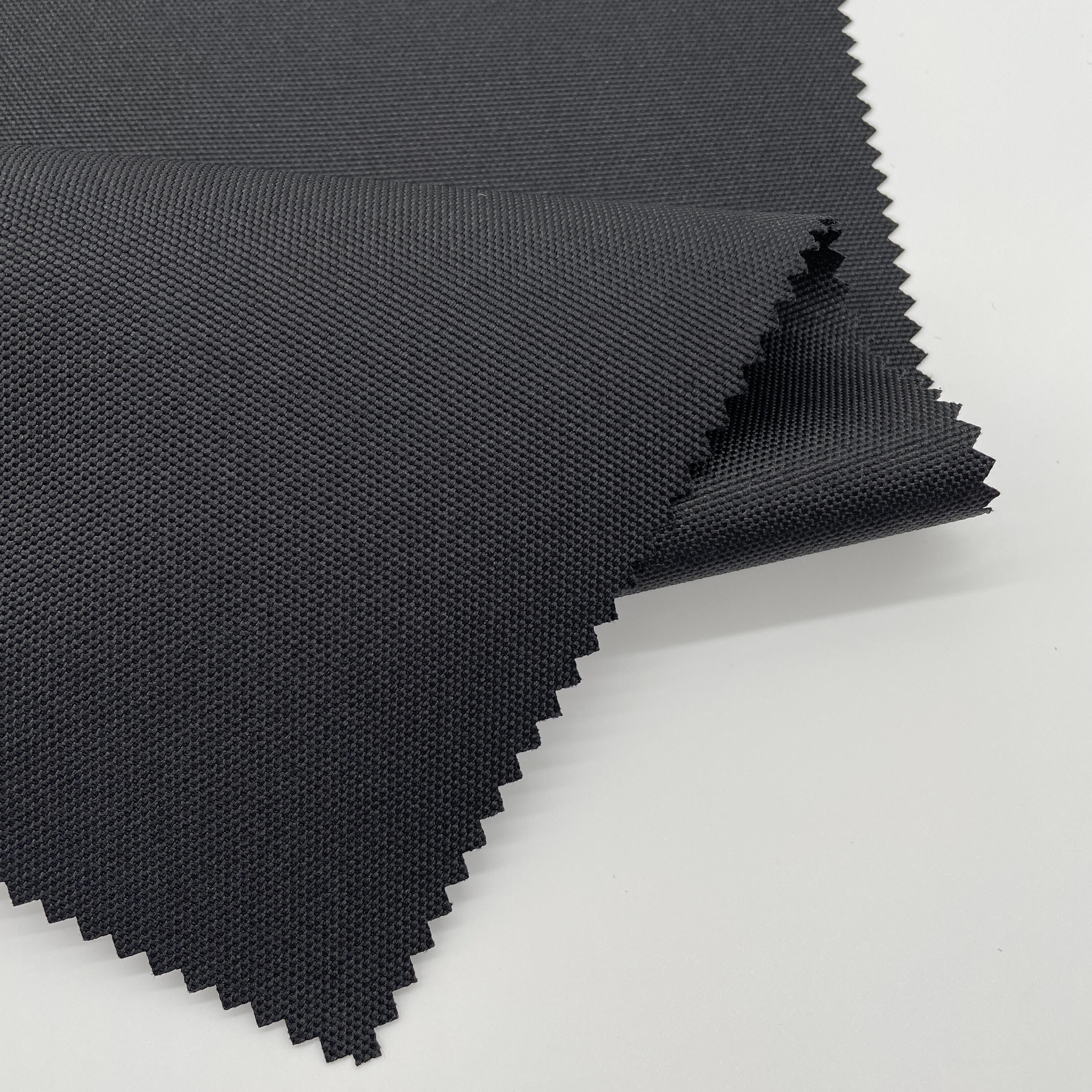

Crafted for the relentless demands of high-performance gear, our advanced fabric leverages the legendary resilience of 80D nylon 6.6 Cordura® as its foundational core. This renowned base material is celebrated for its exceptional tensile strength, outstanding abrasion resistance, and long-lasting durability, ensuring that products built from it can withstand the most challenging environments. The inherent toughness of this specific yarn construction provides a reliable canvas for further technological enhancement, setting a premium standard from the very start.

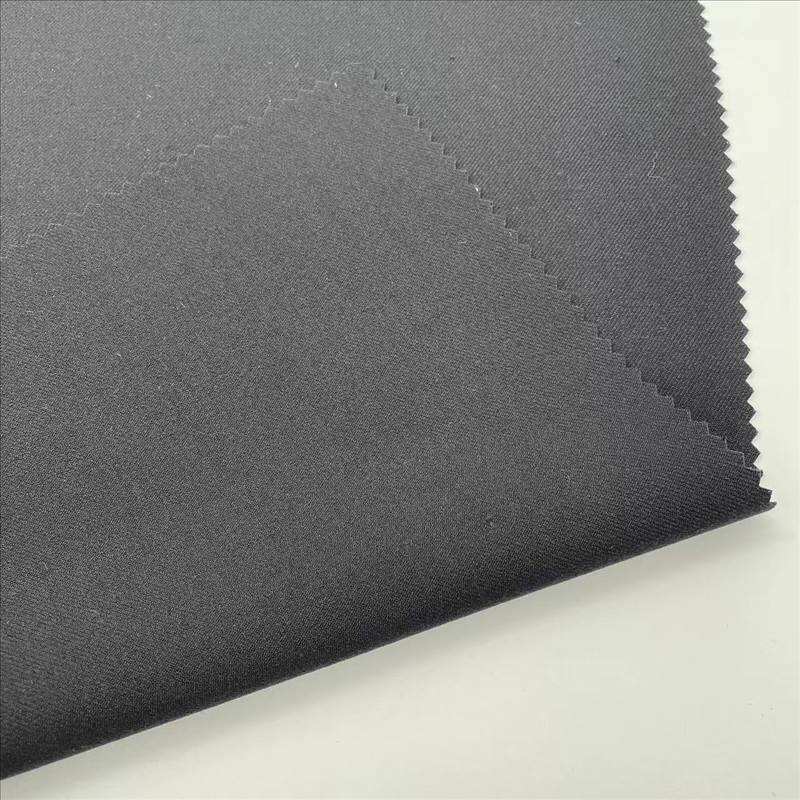

Moving beyond its robust base, the fabric undergoes a sophisticated dual-phase finishing process. First, a meticulous 2-pass polyurethane (PU) coating is applied. This isn't a single-layer treatment; the first pass establishes a primary barrier, which is then meticulously sealed and reinforced by the second application. This method creates an exceptionally uniform and consistent waterproof membrane, effectively blocking moisture penetration while retaining a desirable level of fabric breathability and a supple hand feel. The result is a guaranteed high hydrostatic head rating, ensuring complete dryness.

Finally, the external surface is treated with an advanced Environmental Durable Water Repellent (Eco DWR) finish. This state-of-the-art treatment causes water to bead up and roll directly off the fabric's surface rather than being absorbed. Unlike traditional fluorocarbon-based treatments, our chosen Eco DWR is engineered for reduced environmental impact without compromising performance. It significantly enhances the fabric's ability to shed rain, snow, and grime, and its extended durability means this protective capability persists through repeated wear and cleaning cycles. The synergy between the rugged 80D nylon 6.6 Cordura® base, the impermeable dual PU coating, and the top-tier Eco DWR creates a truly formidable material solution for premium backpacks, technical outerwear, and tactical equipment, offering unparalleled protection and enduring performance.

2. Service Process

Our service is designed for seamless collaboration and precision:

• Consultation & Requirement Gathering: We begin by thoroughly understanding your application, performance needs, design vision, and quantity.

• Material Selection & Proposal: Our technical team proposes the most suitable fabric construction, like the 80D nylon 6.6 Cordura®, along with coating options, presenting samples and a detailed quotation.

• Prototyping & Approval: We produce a prototype fabric batch for your evaluation and testing, ensuring it meets all your specifications before moving to mass production.

• Production & Quality Control: Upon your approval, we initiate production under our stringent quality control protocols, providing regular updates on progress.

• Delivery & Support: The finished goods are meticulously inspected, packaged, and delivered on time, with ongoing support for any future needs.

3. Technical Standards & Quality Control Process

We operate within a framework of rigorous international standards to guarantee product excellence. Our production processes adhere to ISO 9001 quality management principles. The fabric itself is tested against key metrics including:

• Hydrostatic Head (ISO 811): Measuring waterproofing capability.

• Abrasion Resistance (Martindale, ASTM D4966): Quantifying the durability of the fabric and coatings.

• Tensile & Tear Strength (ASTM D5034 / D5587): Verifying the structural integrity of the nylon 6.6 base.

• DWR Performance (AATCC 22): Assessing the water repellency rating.

• Our QC process is integrated at every stage: incoming raw material inspection, in-process checks during weaving and coating, and a final random inspection on 100% of the finished fabric rolls for visual defects, coating consistency, and correct dimensions.

4. Content Depth & Trust Building

We build trust through transparency and expertise. Our detailed technical data sheets provide you with all the necessary information to make an informed decision. We don't just sell fabric; we offer material solutions, providing insights into the best applications and limitations of our products. Our case studies and testimonials from reputable brands in the outdoor and tactical sectors serve as a testament to our reliability and the performance of our materials, such as our coated Cordura® fabrics. We invest in continuous R&D to improve our environmental footprint and performance, ensuring our partners are always ahead of the curve.

5. Why Choose Us?

• Proven Expertise: Deep technical knowledge in high-performance fabrics and functional coatings.

• Uncompromising Quality: A relentless focus on quality control ensures you receive a consistently superior product every time.

• Agile & Flexible: We proudly support OEM/ODM and small-batch customization (from 500 meters), enabling startups and established brands alike to innovate without massive minimums.

• Technical Partnership: We act as an extension of your team, offering expert advice from design to production.

• Responsible Manufacturing: Our use of Eco DWR and other sustainable options demonstrates a commitment to environmental responsibility.

6. OEM/ODM & Customization Support

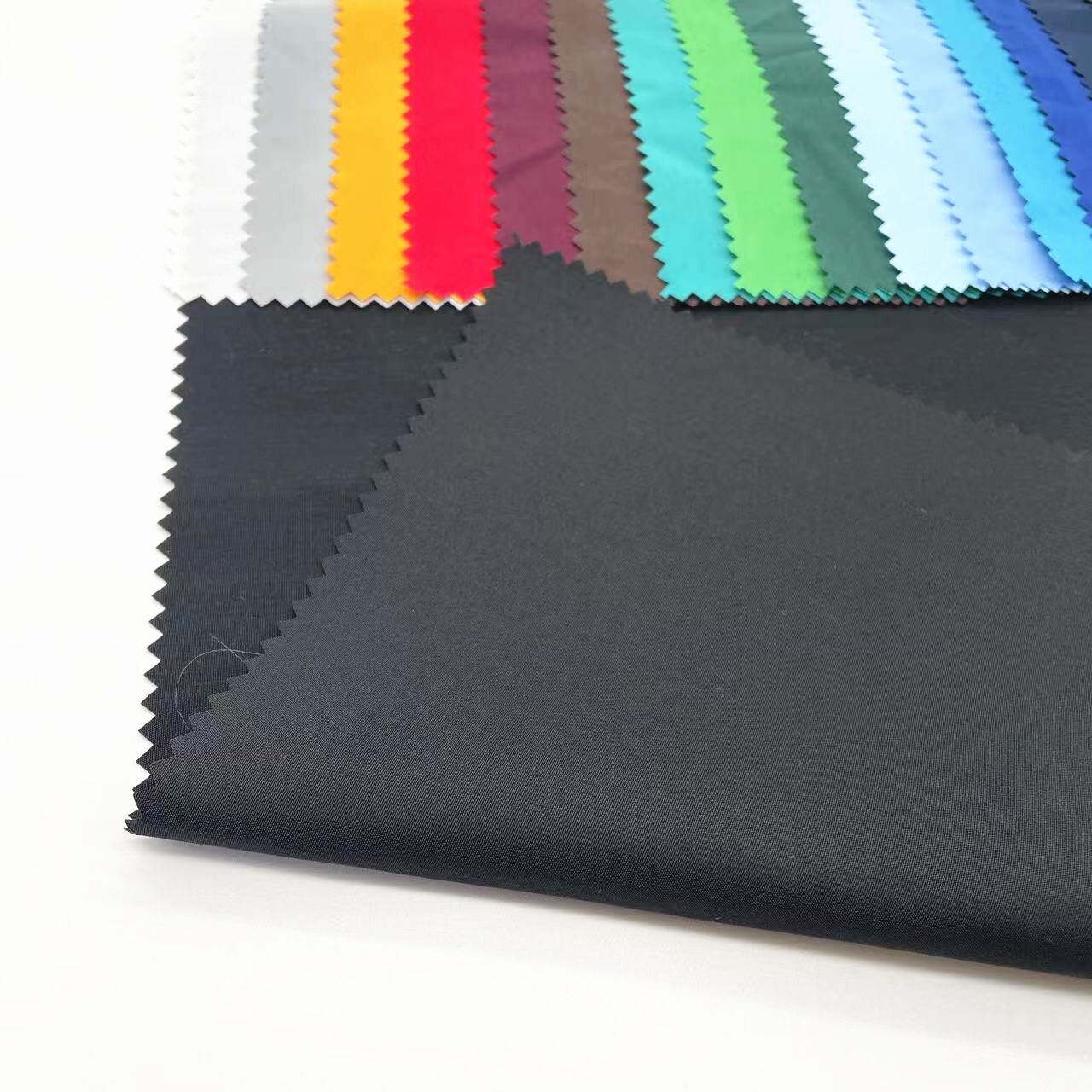

We specialize in customization and are an ideal partner for OEM/ODM projects. Whether you need a specific color match, a unique logo jacquard, a particular hand feel, or a custom-performance PU coating formula, we have the capability to make it happen. We understand the need for market differentiation and support innovative projects with our low small-batch minimum of just 500 meters, allowing you to develop exclusive products, test markets, and launch collections with minimized risk and inventory investment.

Applications:

80D nylon6.6 cordura is used in a variety of heavy-duty applications such as outdoor gear, pet accessories, and military/tactical gear.

Some common uses for this fabric include: Pet beds, luggage, bags, backpacks, tactical gear, horse blankets, wallets, gun cases, insulated food service carriers, footwear, and dog beds.

Specifications:

| Yarn: | 80D*80D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | Plain | Visual |

| Density(in): | W132*F96 | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.14MM | ASTM D 1777 |

| Width: | 58'' | ASTM D 3774 |

| Weight: | 2.95oz/sq yd | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:92N, F: 88N | ISO 13937-3 |

| Tensile strength 1'': | W:760N, F:553N | ISO 13934-1 Strip method |

| Abrasion Resistance: | Over 1000cycles | ASTM D3884-09 |

Competitive Advantage:

Taiwan Weaving Quality

Factory direct sell price

High tensile

Super durability

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ