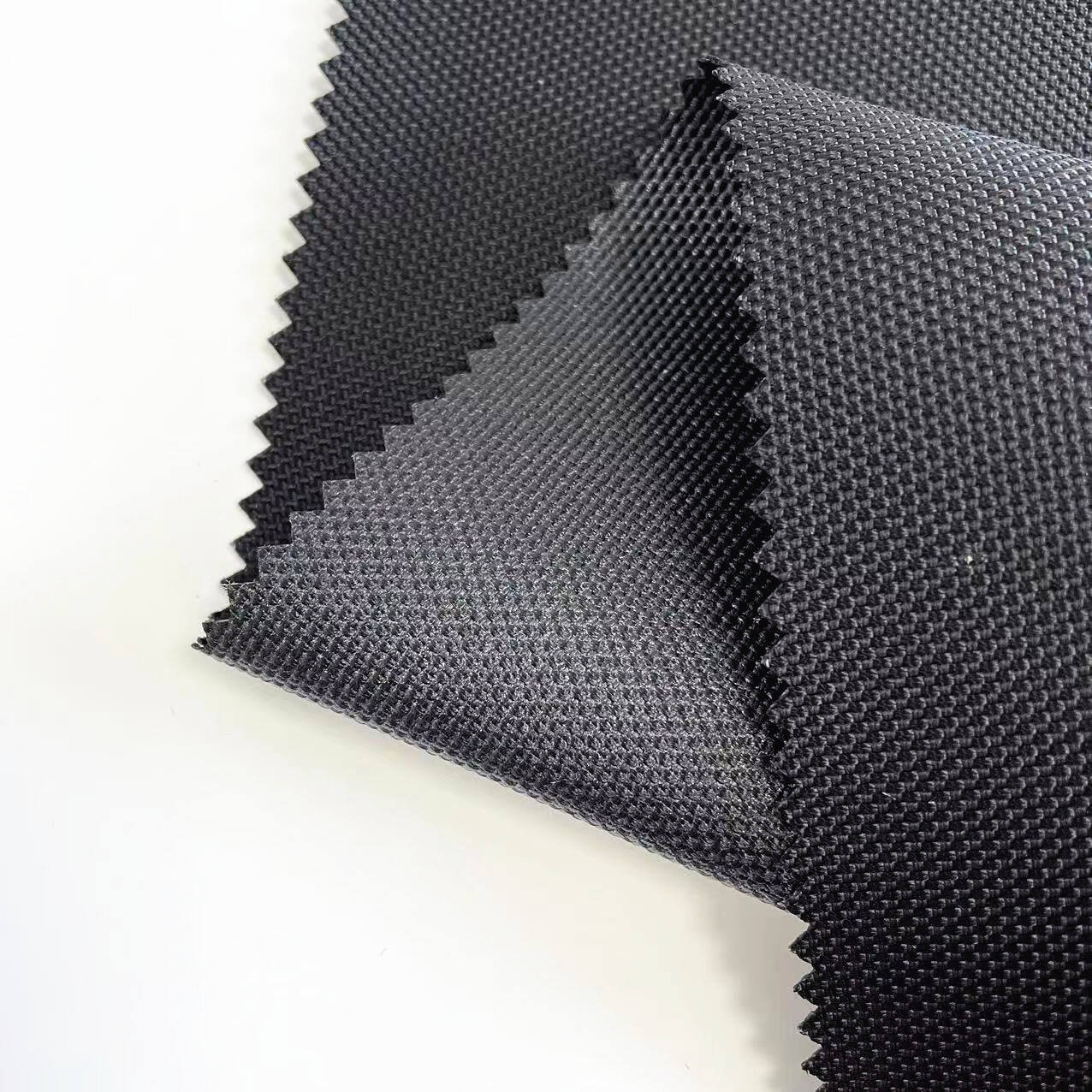

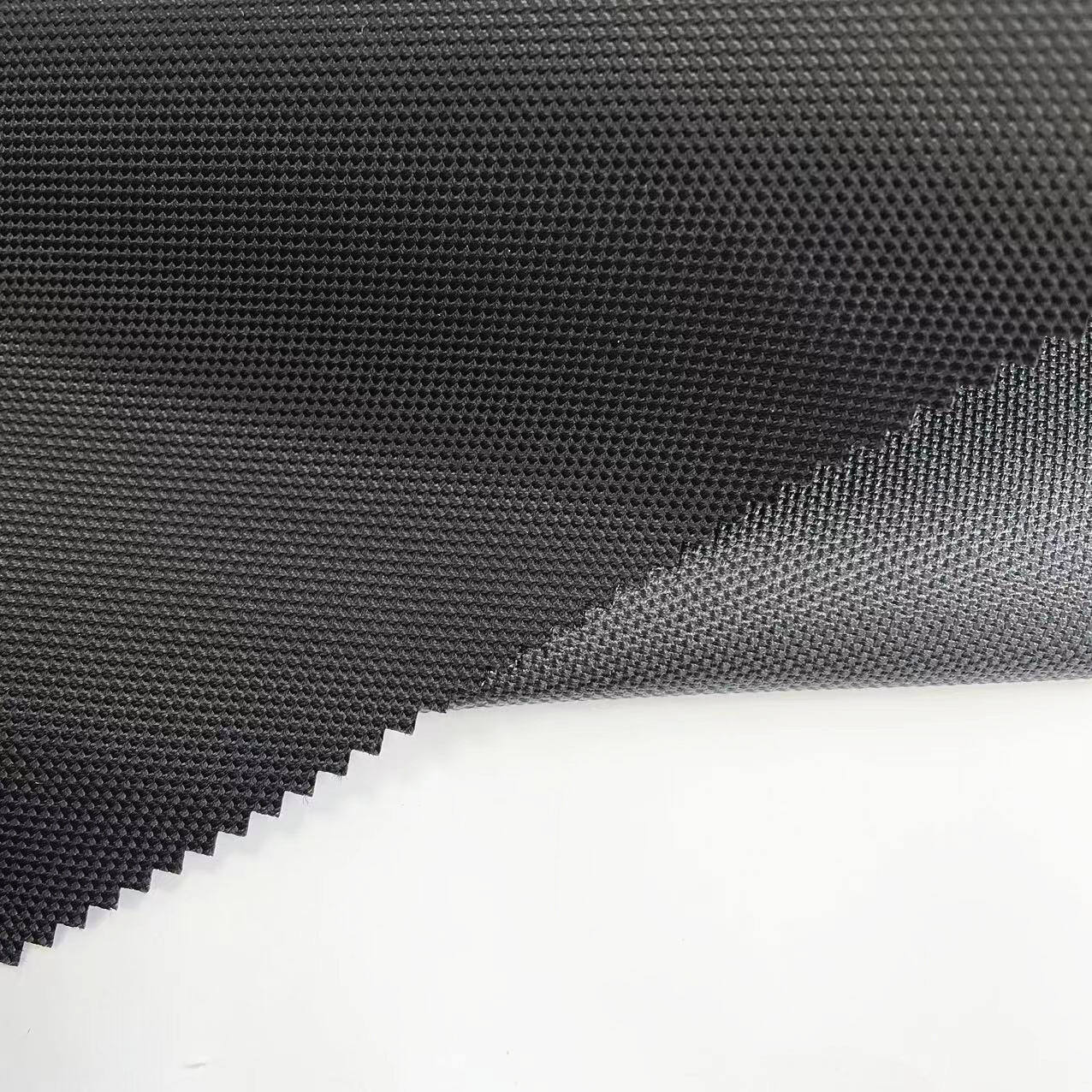

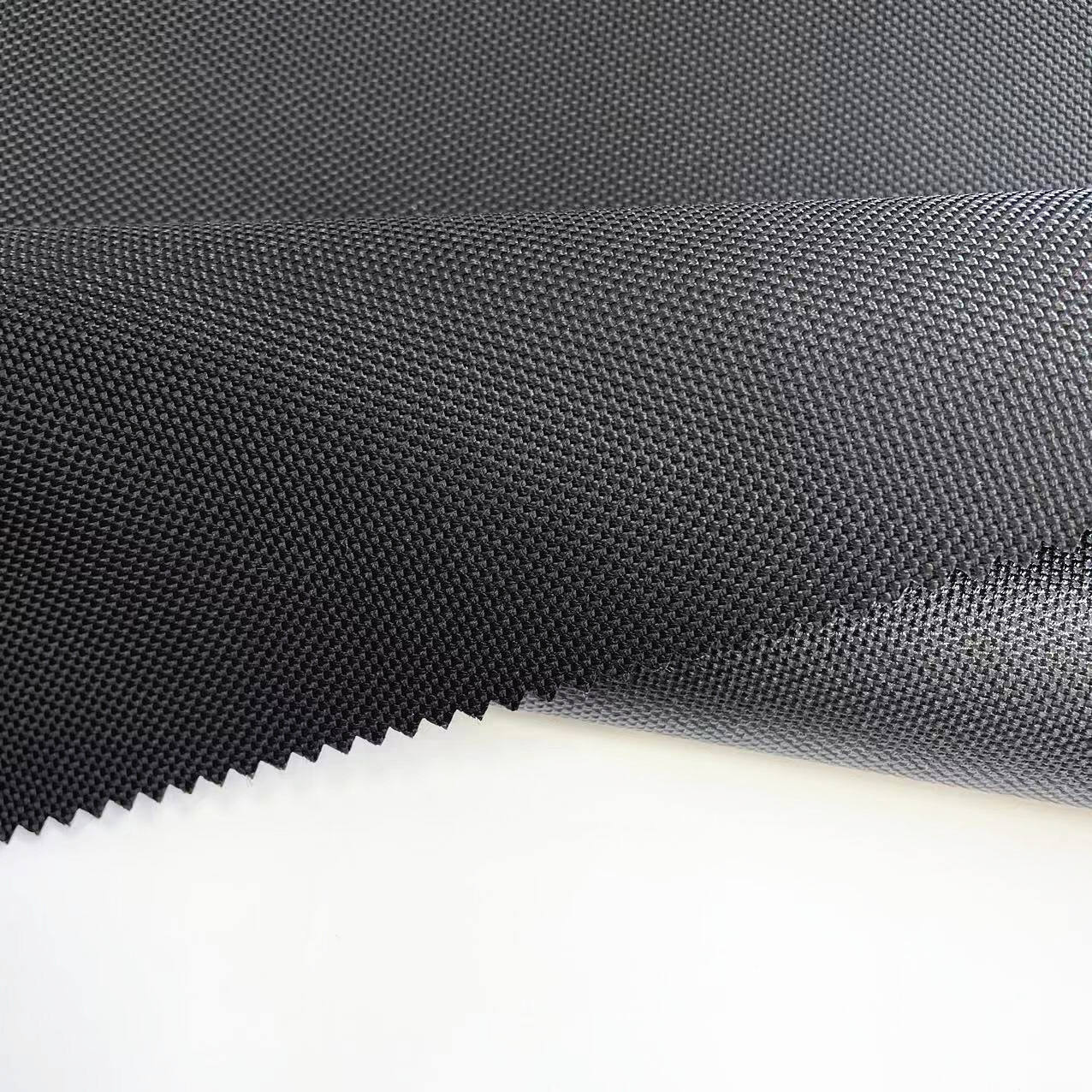

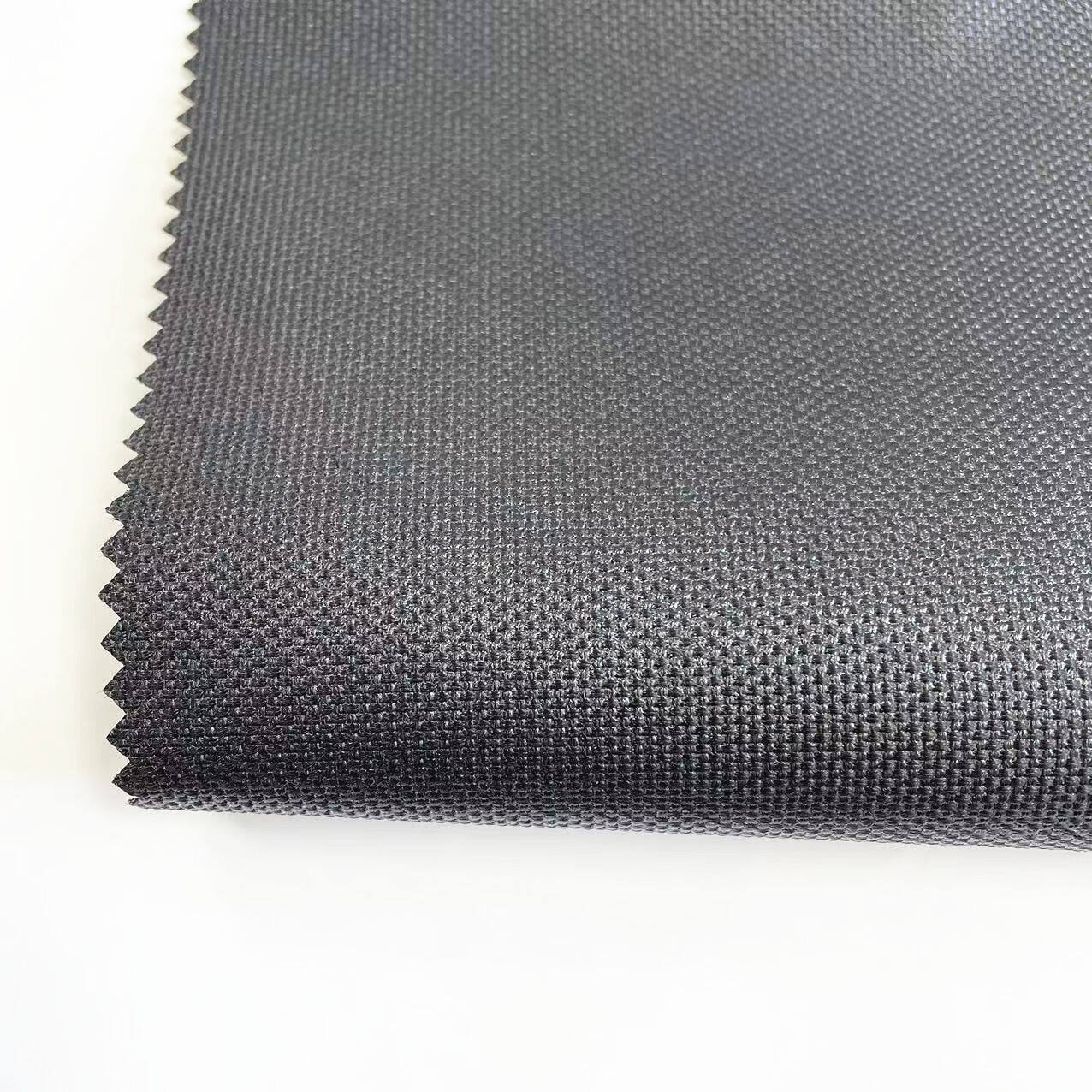

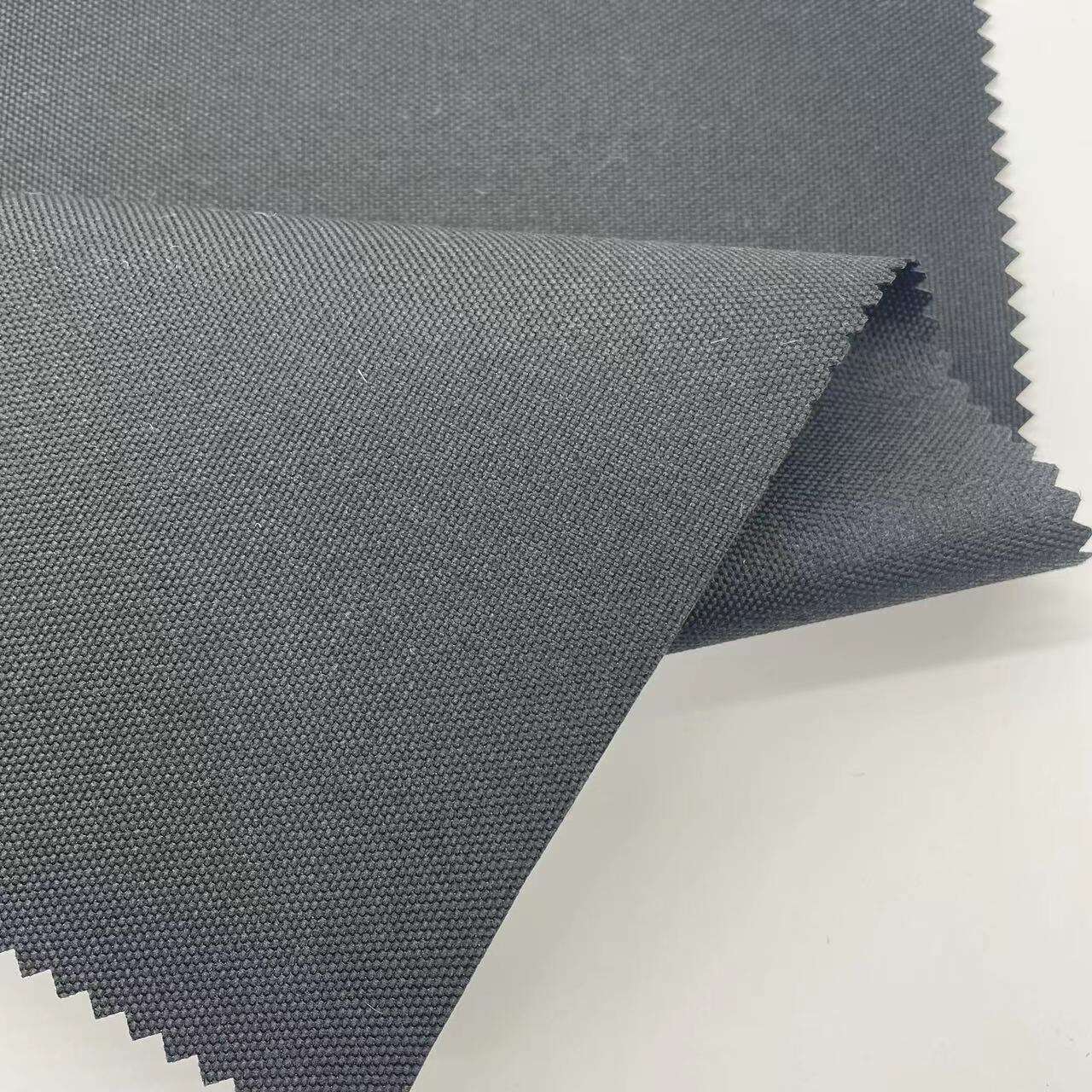

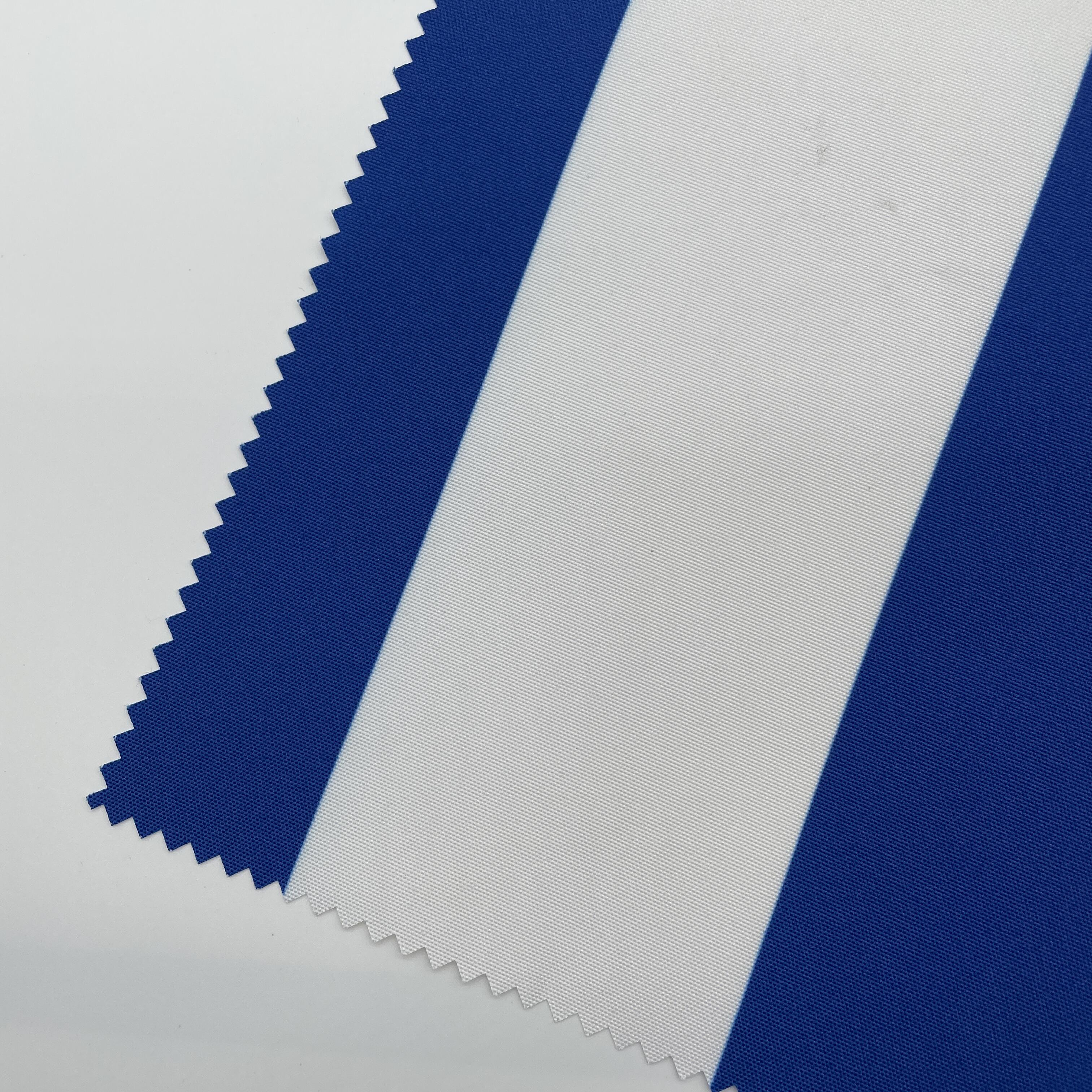

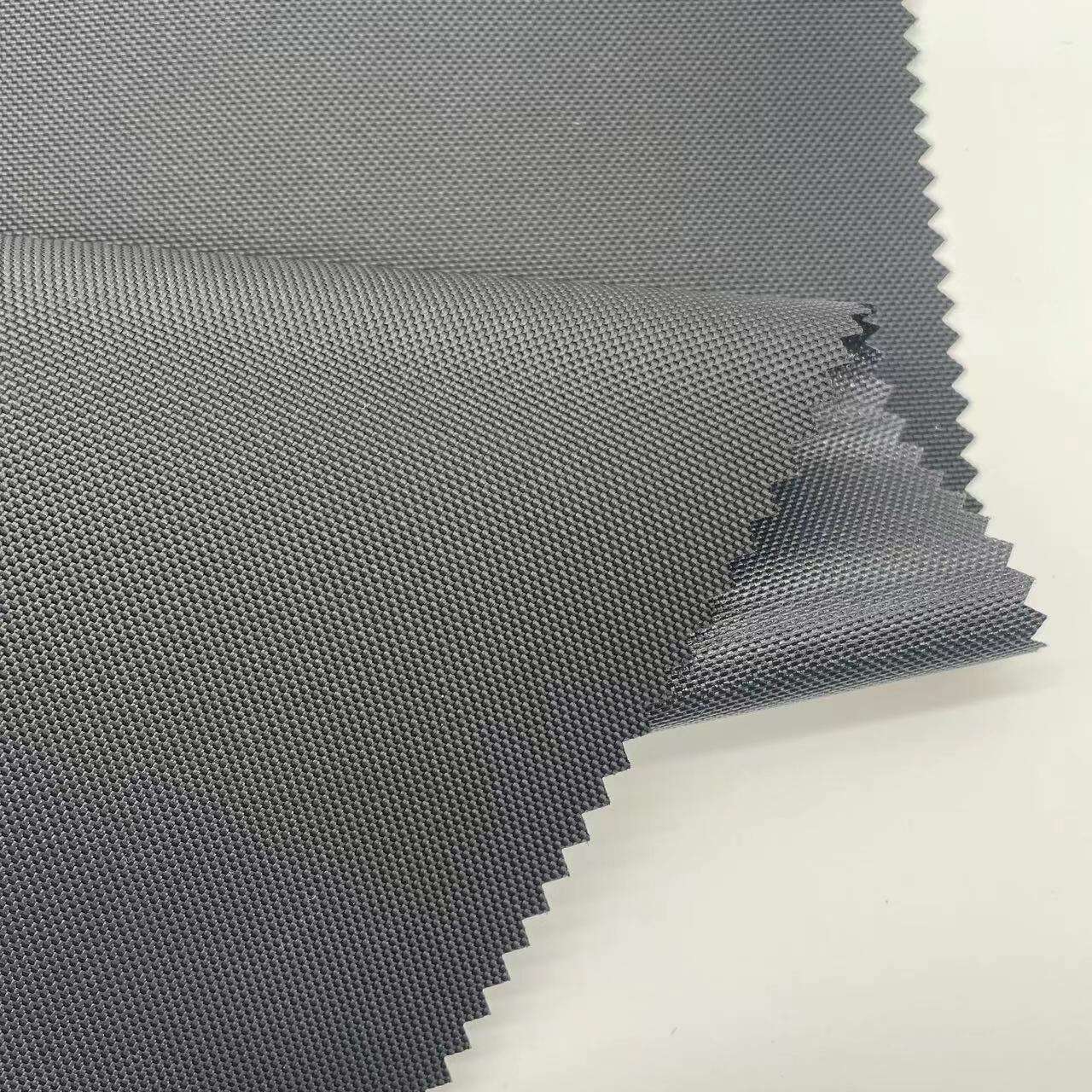

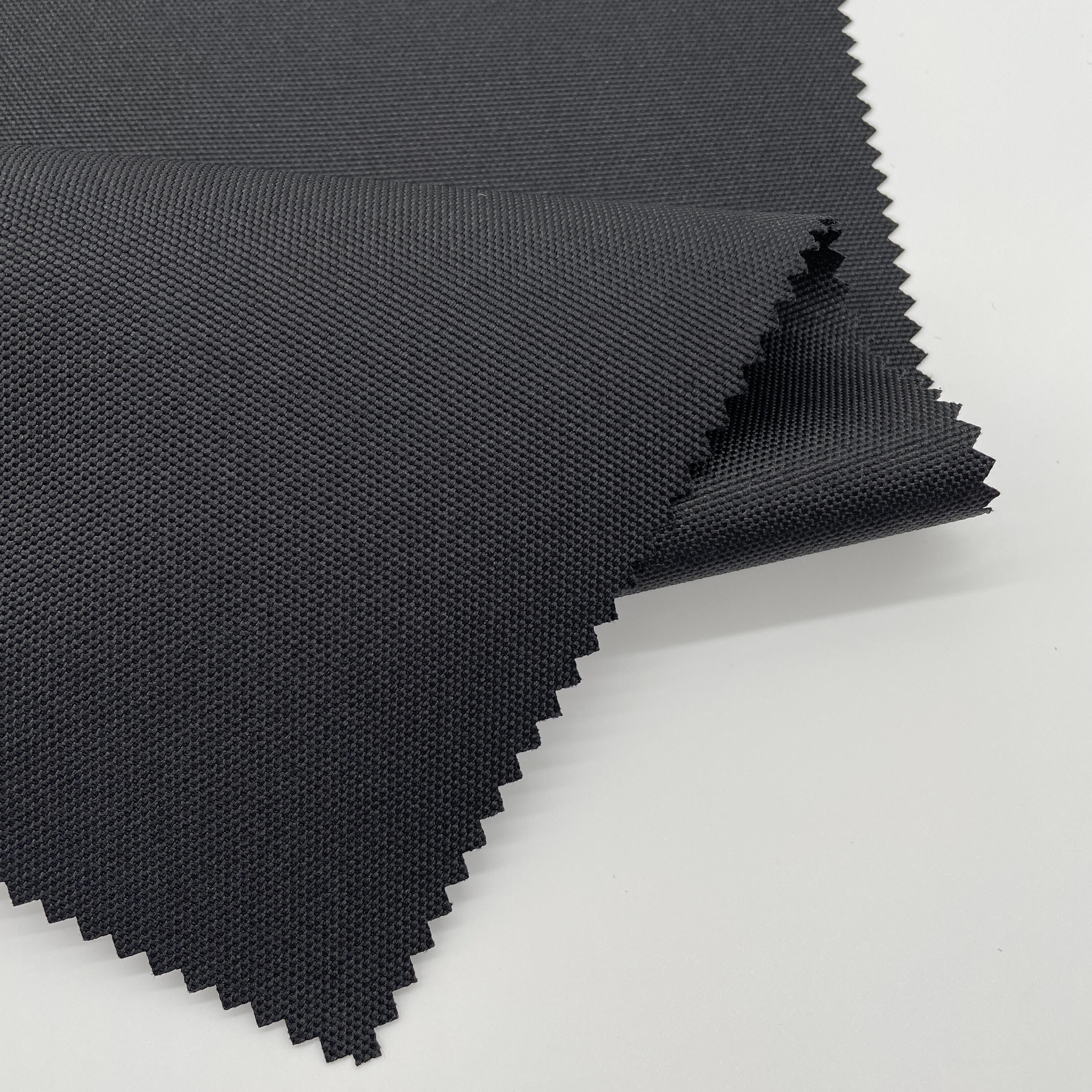

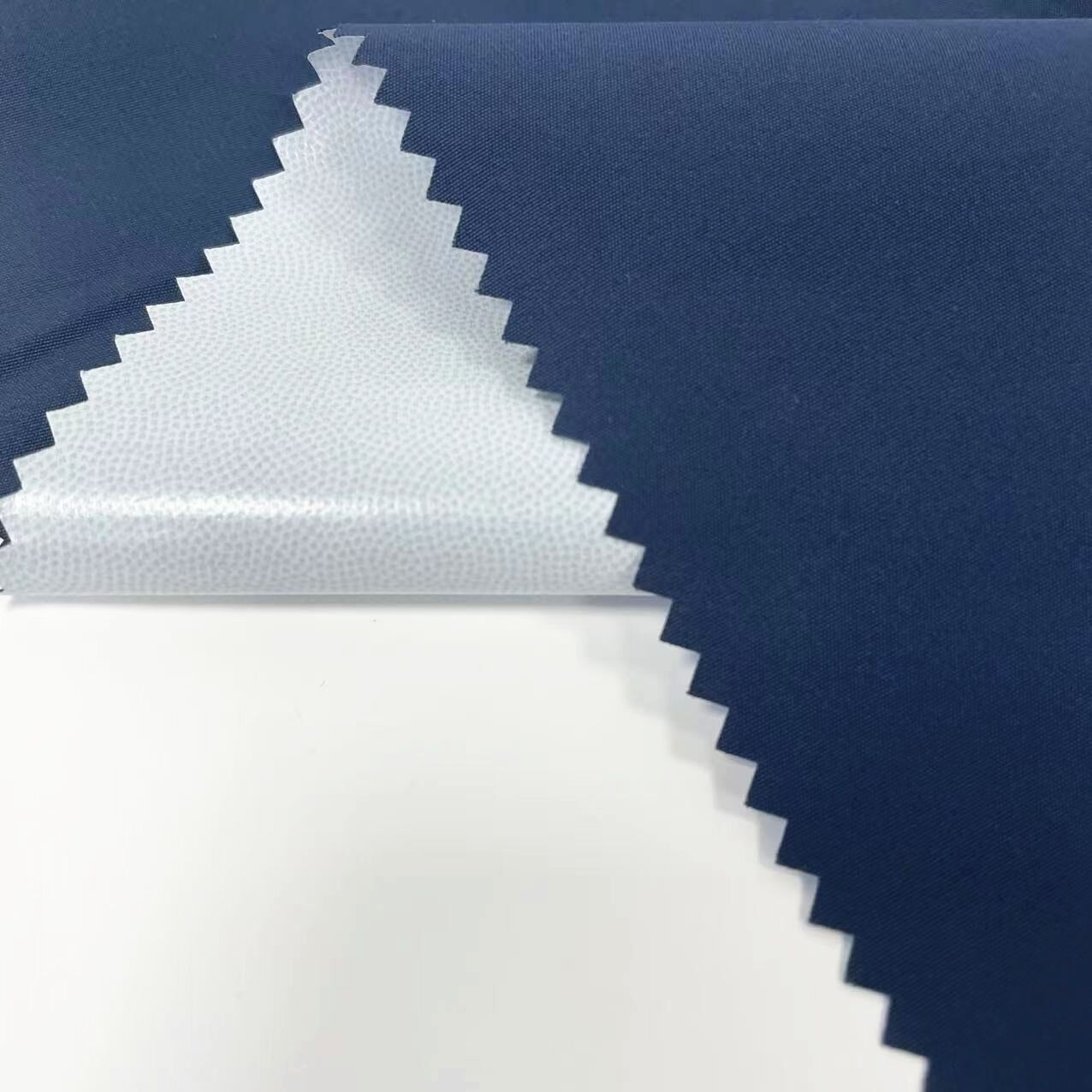

1680 Denier Coated ballistic nylon fabric with Durable Water Repellent Finish

| Content: | Nylon |

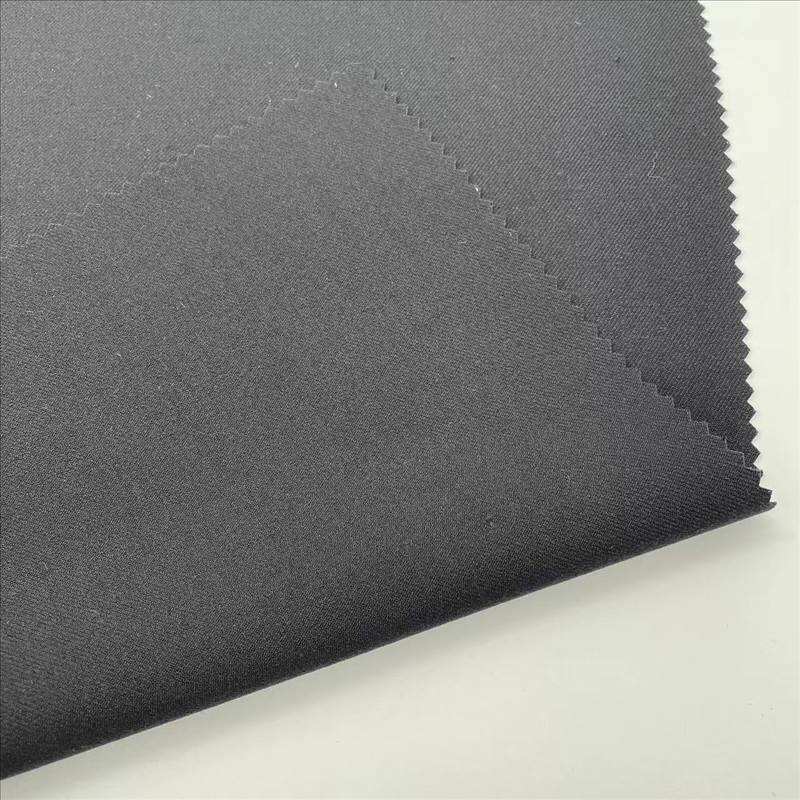

| Coating: | PU(Polyurethane) |

| Country of origin: | TAIWAN |

| Weaving: | 2x2 basket weave |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

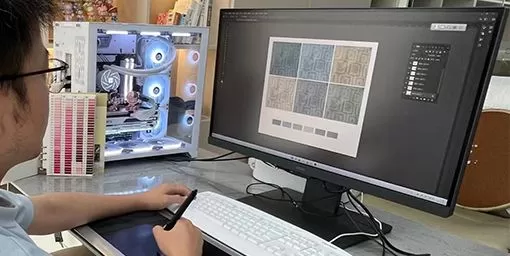

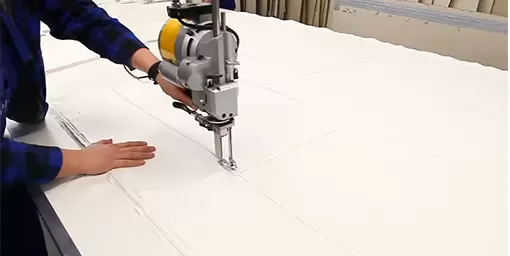

- Process flow

- Related products

- Inquiry

Parameter

1680D coated Ballistic Nylon fabric is a super strong, durable, and water repellent fabric. “Ballistic” does not mean it is bullet proof but to be anti-fragment resistant for the military to prevent injuries from ballistic impact like flying debris or shrapnel. Ballistic Nylon fabric with a polyurethane coating on the back and durable water repellent finish on the front. It offers exception abrasion, puncture and tear resistance. 1680D is going to be even tougher against abrasion and tears than 1000D. Ballistic Nylon will hold up extremely well in any weather, temperature, and/or water it encounters.

Engineered for extreme durability and superior weather resistance, our 1680 Denier Coated ballistic nylon fabric represents the pinnacle of heavy-duty textile innovation. Originally developed for military and tactical applications, this fabric combines exceptional tear and abrasion resistance with a advanced Durable Water Repellent (DWR) finish, making it ideal for high-performance gear requiring ultimate protection and longevity. Whether for protective cases, tactical equipment, or premium outdoor gear, this material delivers unmatched reliability in the most demanding conditions.

The exceptional strength of this 1680 Denier Coated ballistic nylon fabric comes from its unique 2x2 basket weave construction using high-tenacity nylon yarns. This dense structure provides inherent resistance to cuts, tears, and abrasions, far surpassing standard fabrics. The material is then treated with a premium polymer coating and a sophisticated DWR finish, creating a surface that causes water to bead up and roll off while still allowing for limited breathability. This combination ensures that goods and equipment remain protected from moisture, impacts, and daily wear. The rugged yet refined appearance of this ballistic nylon fabric makes it equally suitable for professional applications and premium consumer products where both performance and aesthetics matter.

Rigorous Quality Assurance and Certification:

We maintain exacting standards for every meter of fabric produced. Our 1680 Denier Coated ballistic nylon fabric undergoes comprehensive testing for tear strength (ASTM D1424), abrasion resistance (ASTM D3884), water resistance (AATCC 22), and coating adhesion. We provide detailed test reports with each shipment, ensuring full transparency and compliance with international standards. Our quality control process includes multiple inspection points from raw material selection to finished fabric, guaranteeing consistent performance batch after batch.

Why Partner With Us:

Low MOQ Flexibility: We support both large-scale production and development projects with a minimum order quantity of just 1000 meters, enabling prototyping and small-batch manufacturing without excessive inventory commitment.

Technical Collaboration: Our service includes dedicated technical support from concept to production, including sample development, application guidance, and manufacturing recommendations.

Proven Reliability: Our fabrics are trusted by military contractors, outdoor brands, and industrial equipment manufacturers worldwide for consistent quality and performance.

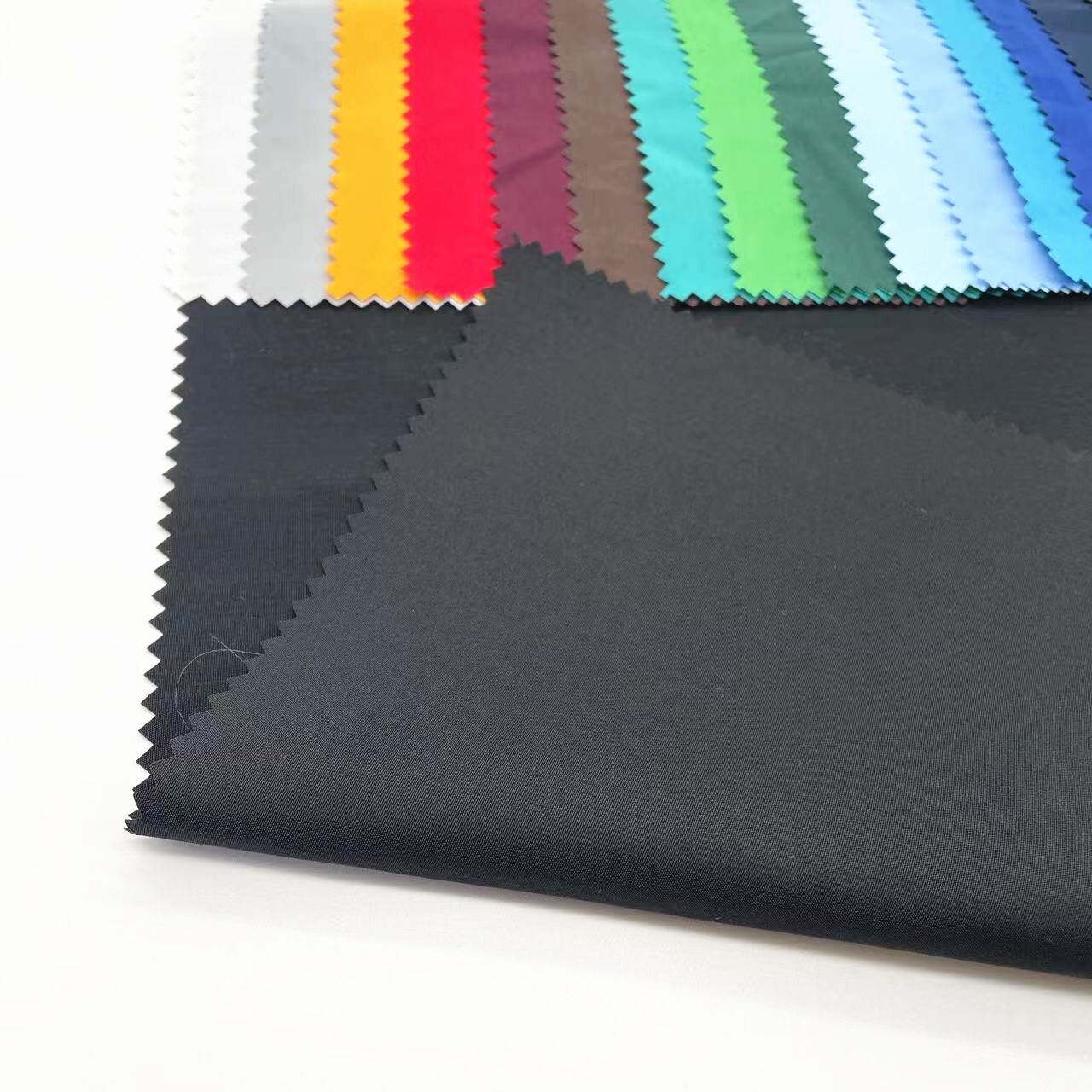

Customization Options: We offer various coating weights and finish variations to meet specific application requirements.

Choose our 1680 Denier Coated ballistic nylon fabric for applications where failure is not an option. This fabric provides the ultimate combination of protection, weather resistance, and professional appearance for your most demanding products. Contact us today to discuss your specific requirements and request. samples for testing.

Applications:

1680D is commonly used for military use, outdoor use, and creating heavy duty gear.

Some common uses for this fabric include: briefcases, horse blankets, pet beds, luggage, kayak/boat covers, tactical gear, tool belts, watch straps, and police belts, soft-sided luggage, packs, knee, seat and calf strengthening on work wear, motorcycle chaps and apparel, office furniture, work and tool belts, and other items where abrasion resistance is a key characteristic.

Specifications:

| Yarn: | 840D/2*840D/2 | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | 2*2 basket plain | Visual |

| Density(in): | W28*F20 | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.55MM | ASTM D 1777 |

| Width: | 60'' | ASTM D 3774 |

| Weight: | 10.65 oz/sq yd | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:124LBF, F: 91LBF | ASTM D2261-13 |

| Tensile strength 1'': | W:690LBF, F:542LBF | ASTM D5034-21 Grab test |

| Abrasion Resistance: | Over 1000cycles | ASTM D3884-09 |

Competitive Advantage:

Taiwan Weaving Quality

Factory direct sell price

High tensile

Super durability

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ