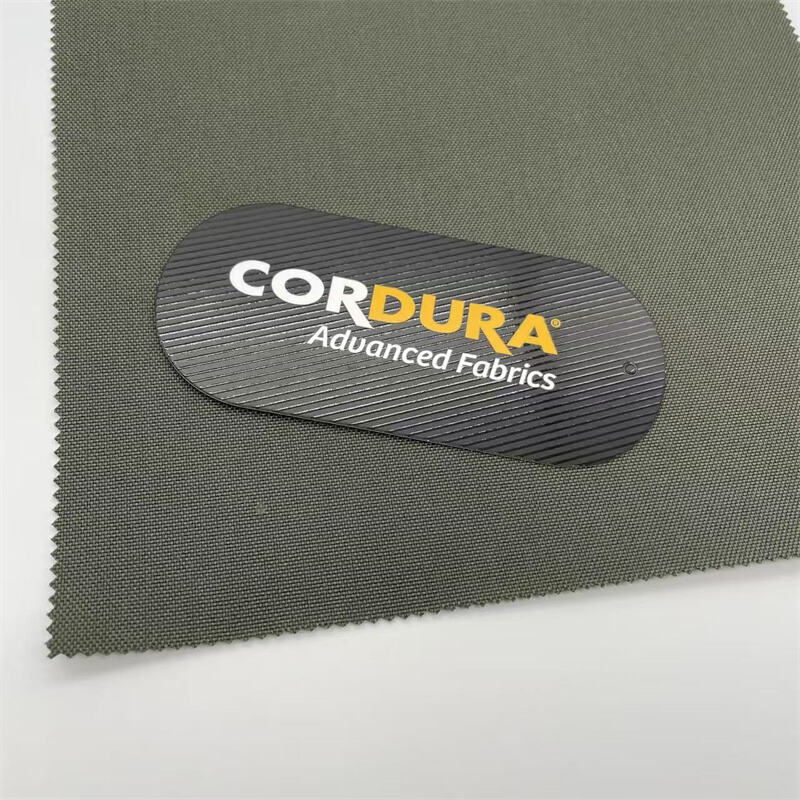

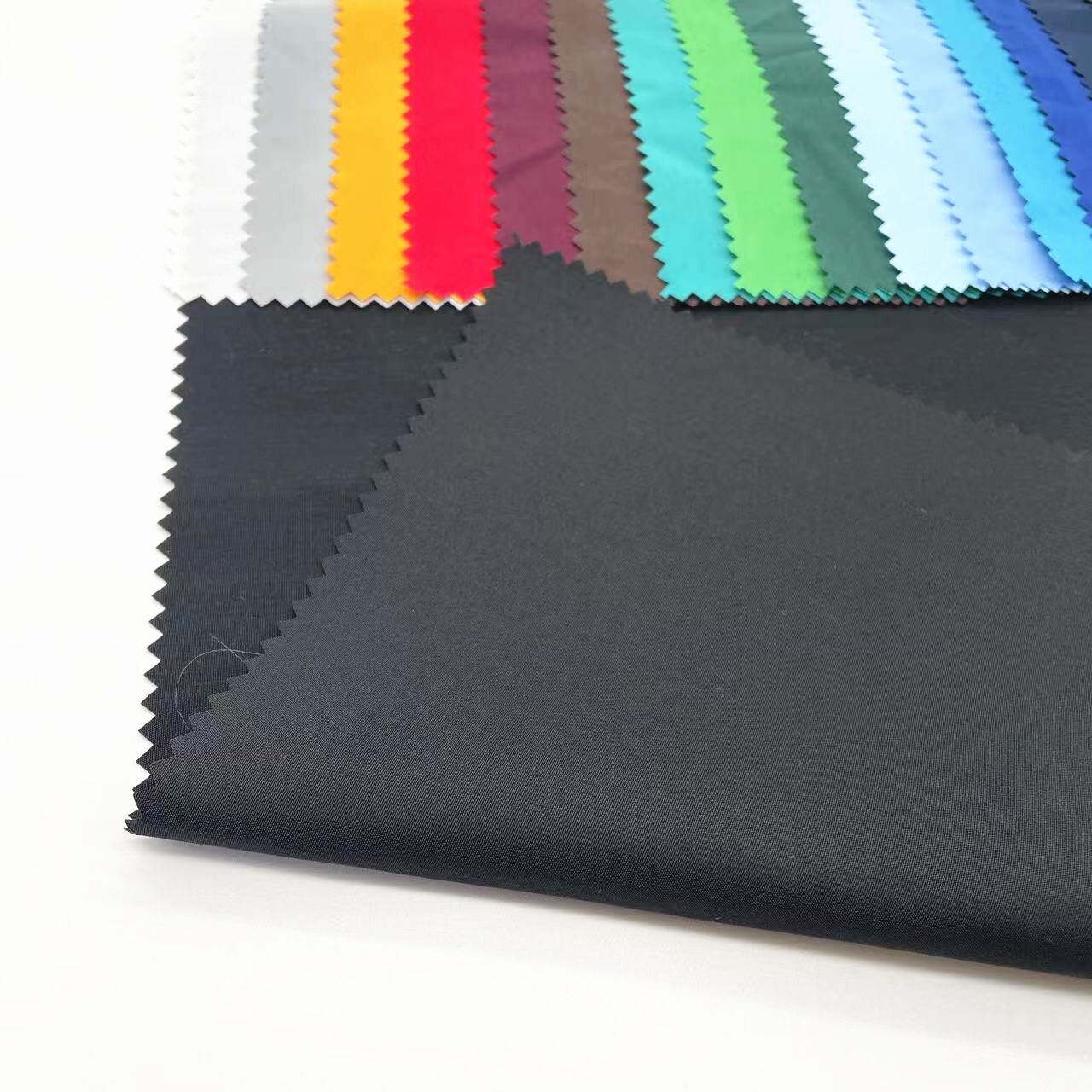

PFAS free Water repellent 500D nylon6.6 cordura fabric with 2 pass PU coating 2935BR-RE

| Content: | Nylon |

| Coating: | PU(Polyurethane) |

| Country of origin: | US |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

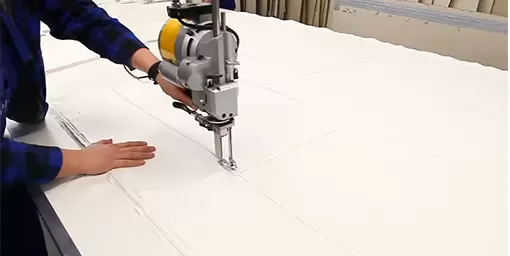

- Process flow

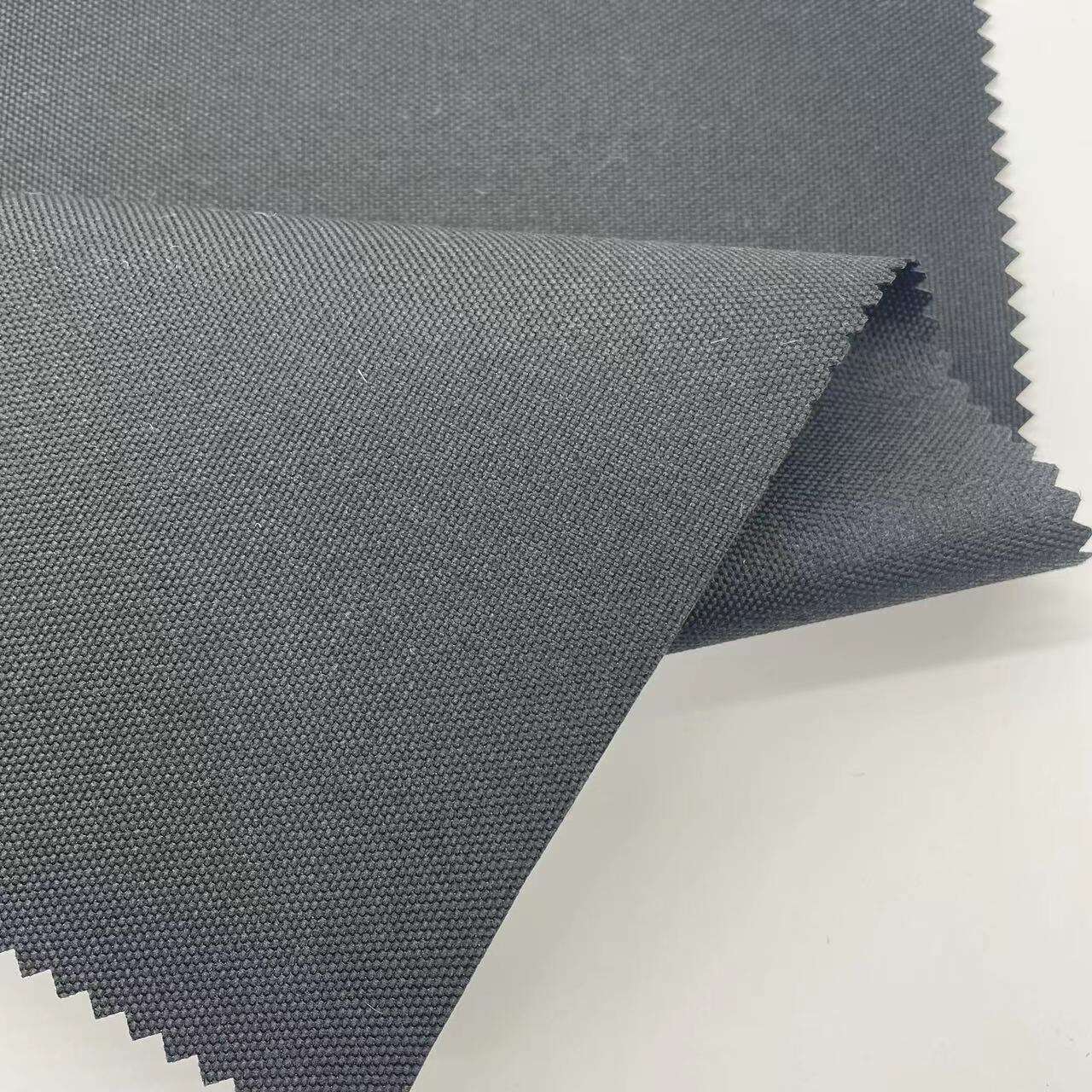

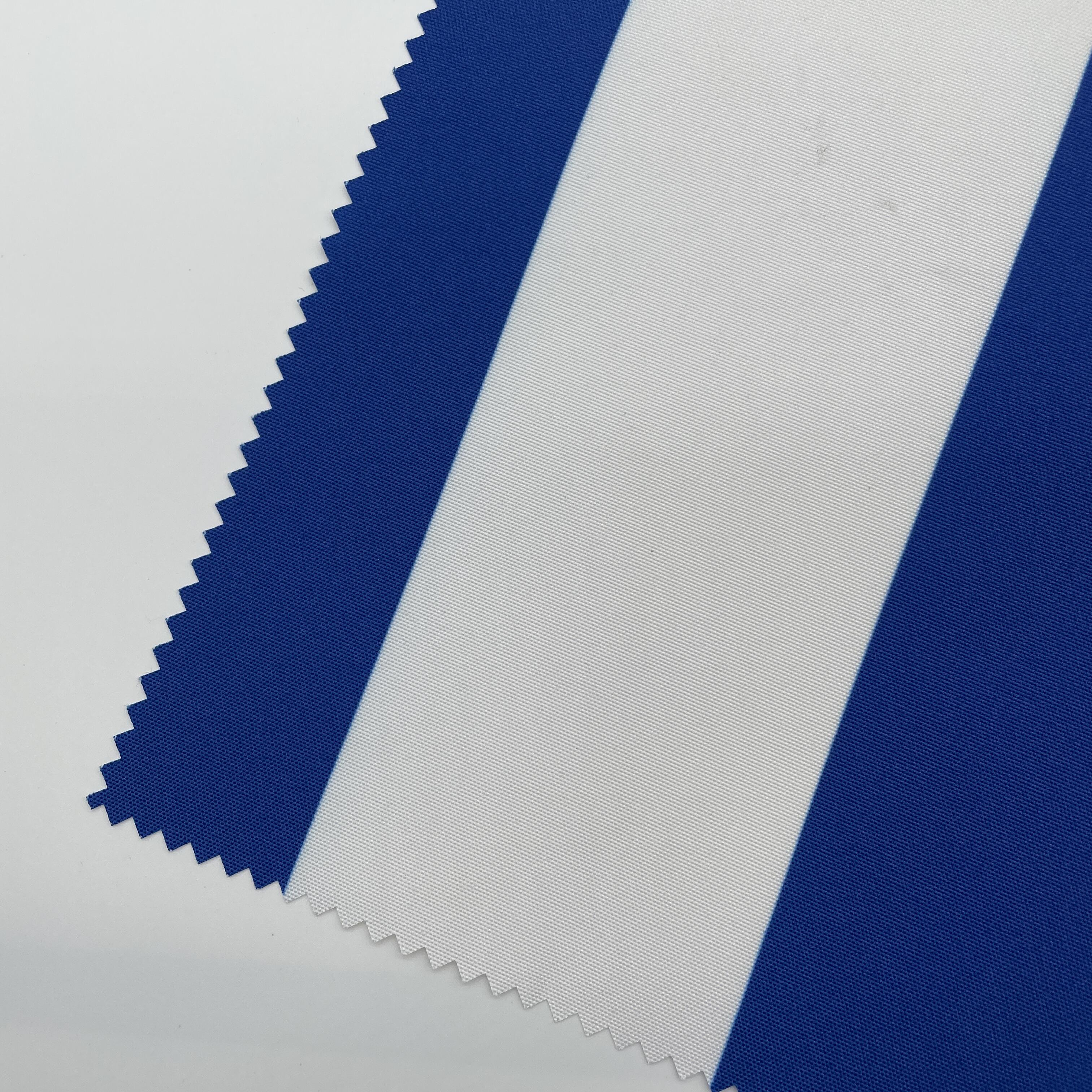

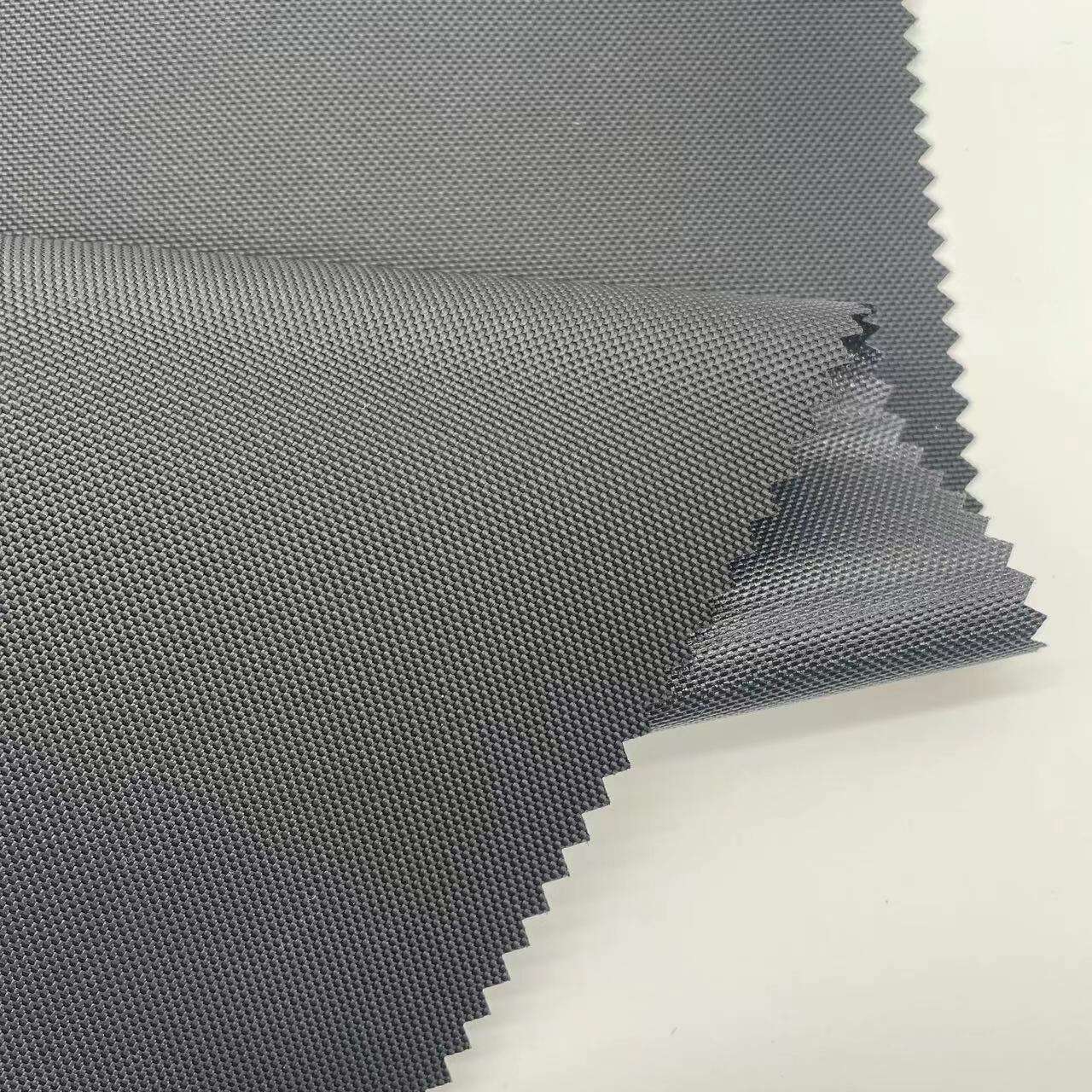

- Related products

- Inquiry

Parameter

500D Nylon Cordura Fabric with 2-Pass PU Coating & Eco DWR

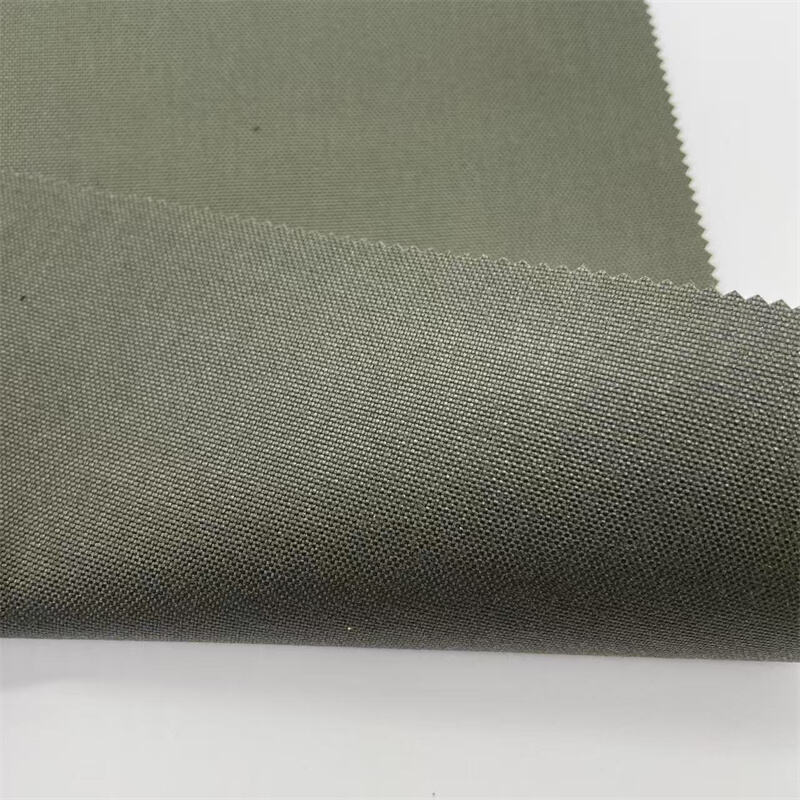

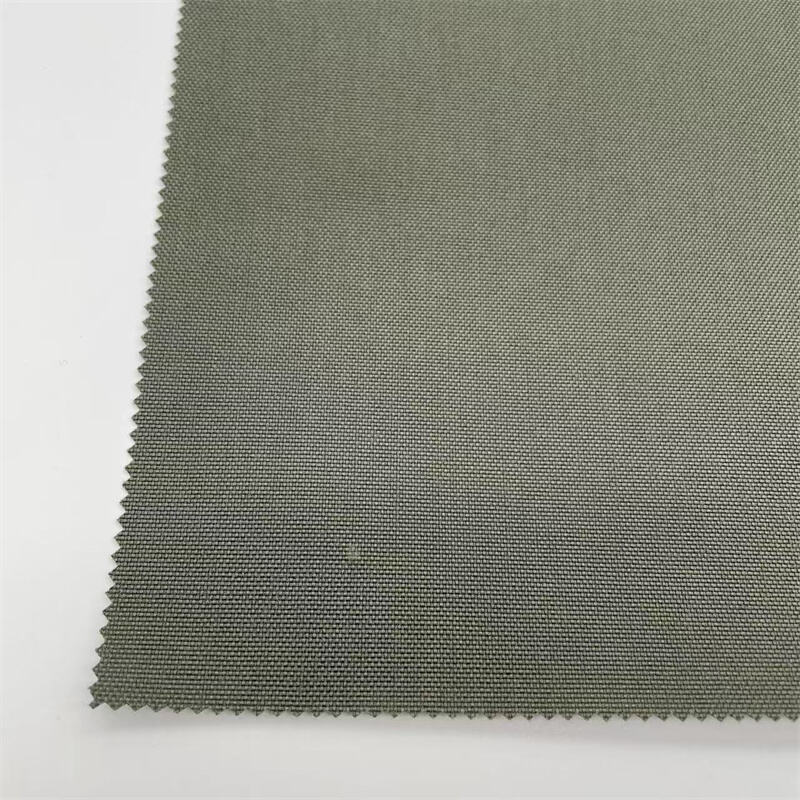

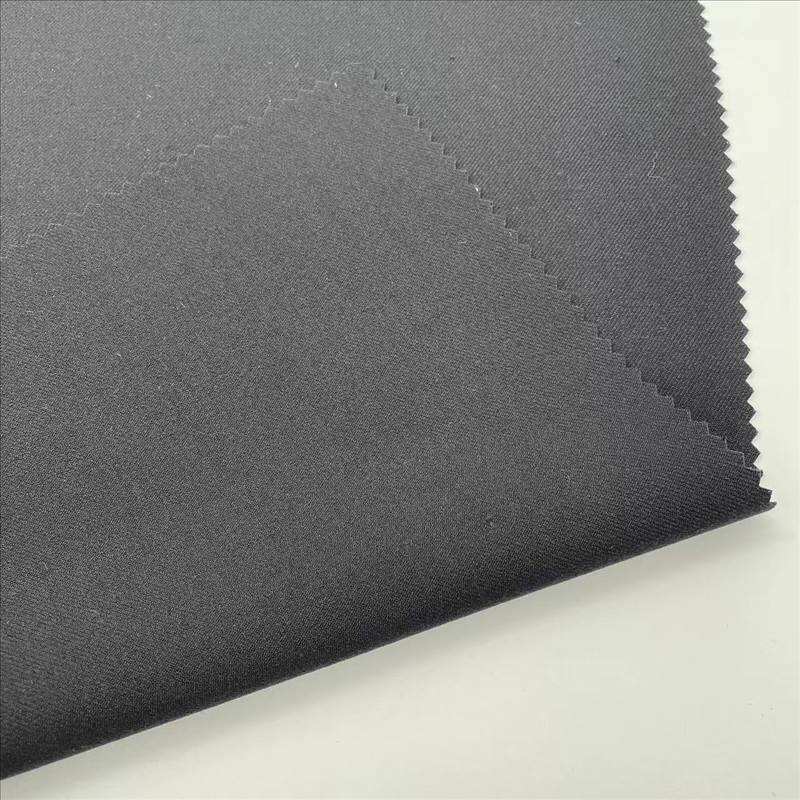

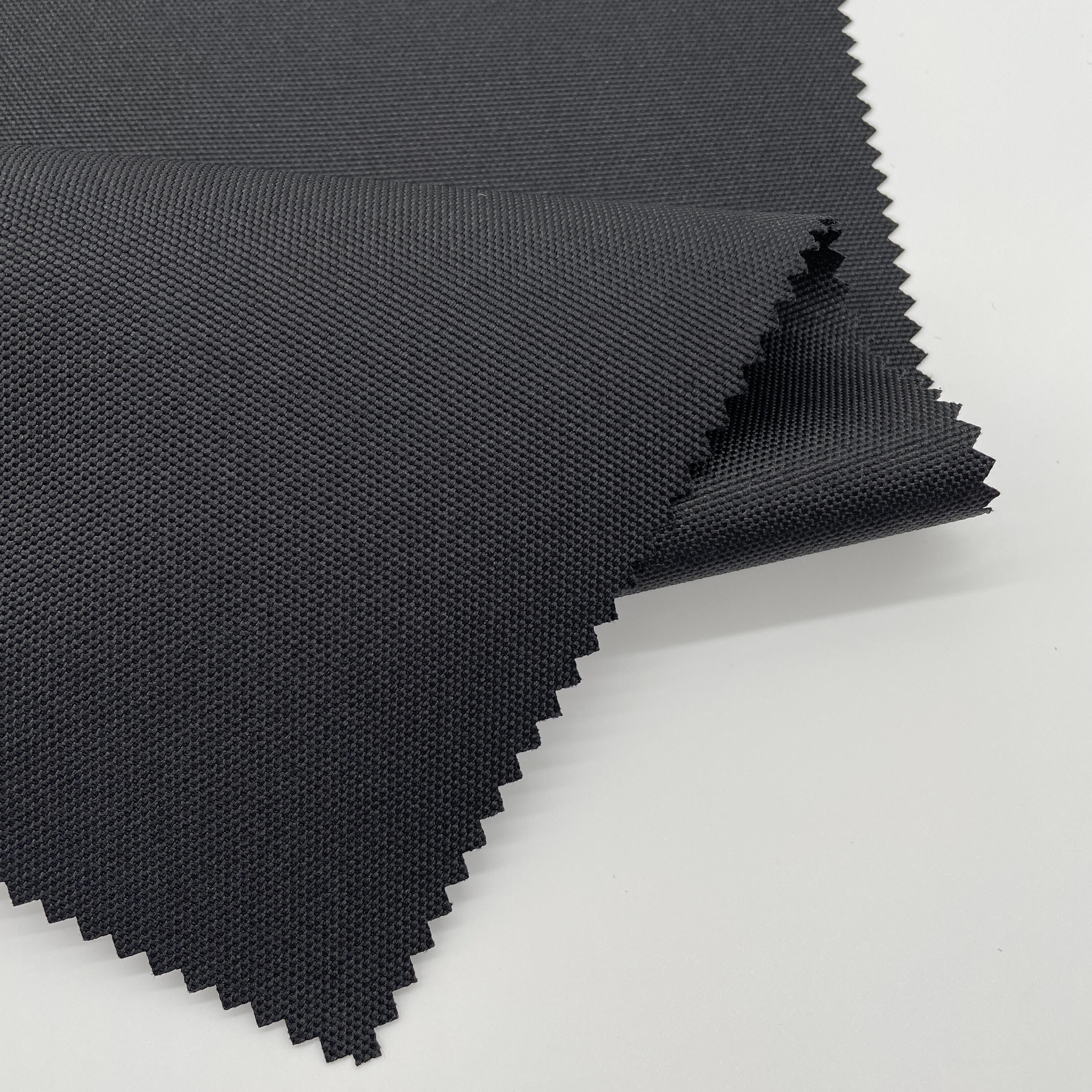

Designed for the most demanding applications where superior durability is non-negotiable, this heavyweight fabric represents the pinnacle of rugged performance. Constructed from exceptionally resilient 500D nylon Cordura fabric, this material boasts an outstanding strength-to-weight ratio, providing unparalleled resistance to abrasion, scuffs, and tears. The high-denier yarns create a robust, textured surface that is instantly recognizable for its premium quality and ability to withstand prolonged, heavy-duty use in the toughest environments, from tactical operations to industrial workwear.

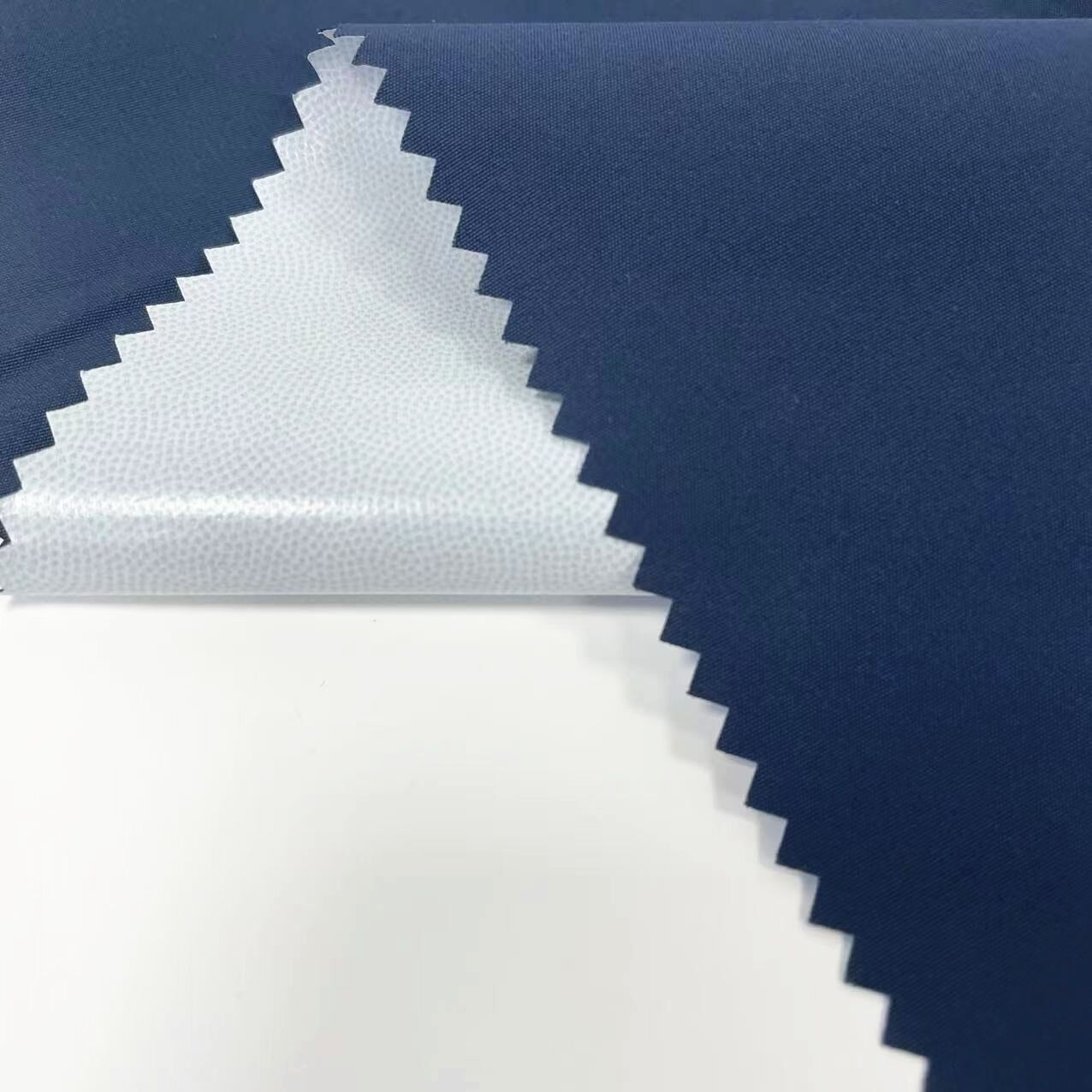

The inherent toughness of this base material is significantly enhanced through our advanced dual-phase coating technology. A meticulous 2-pass polyurethane (PU) coating process is applied to create an impermeable barrier. The initial coating layer penetrates the fabric structure, establishing a foundational seal, while the second pass builds upon this to form a continuous, fully bonded membrane. This results in exceptional waterproofing performance with a high hydrostatic head rating, ensuring complete protection against moisture ingress while maintaining the fabric’s structural integrity and flexibility.

Completing this robust defensive system is an environmentally conscious Durable Water Repellent (Eco DWR) finish. This advanced treatment creates a protective molecular barrier on the fabric surface, causing liquids to bead up and roll away immediately rather than being absorbed. The eco-friendly formulation delivers superior water and stain resistance without compromising environmental values, maintaining its effectiveness through extended wear and cleaning cycles. The powerful combination of the rugged 500D nylon Cordura fabric, the impervious dual PU coating, and the advanced Eco DWR treatment creates an ultimate protection solution for premium tactical gear, heavy-duty luggage, protective equipment, and high-performance outdoor products that demand maximum durability and weather resistance.

2. Service Process

Our customer-centric approach ensures a seamless experience from concept to delivery:

• Requirement Analysis: We begin with comprehensive discussions to understand your specific application needs, performance requirements, and design objectives.

• Technical Proposal: Our engineering team develops customized solutions, providing detailed technical specifications and material samples for evaluation.

• Prototype Development: We create production-representative samples for your testing and validation, ensuring all performance metrics are met.

• Quality Manufacturing: Upon approval, we execute production with strict quality monitoring at each manufacturing stage.

• Certified Delivery: We conduct final comprehensive inspections and provide quality certificates with each shipment.

3. Technical Standards & Quality Control Process

We maintain excellence through rigorous certification and testing protocols. Our manufacturing processes comply with ISO 9001 quality management systems and meet military-grade standards (MIL-SPEC) where applicable. Each batch undergoes comprehensive testing including:

• Abrasion Resistance (ASTM D3884): Verifying the exceptional durability of the 500D nylon Cordura fabric.

• Hydrostatic Resistance (ISO 811): Testing waterproof performance under pressure.

• Tensile Strength (ASTM D5035): Measuring load-bearing capacity.

• Color Fastness (AATCC 61): Ensuring color durability through washing and exposure.

• DWR Performance (AATCC 22): Quantifying water repellency effectiveness.

• Our multi-tier QC system includes raw material verification, in-process checks during weaving and coating, and final inspection against 27 quality parameters.

4. Content Depth & Trust Building

We establish long-term partnerships through transparency and expertise. Our technical team provides detailed application engineering support, helping you optimize designs for manufacturability and performance. We maintain complete traceability throughout our supply chain and provide full material composition documentation. Our case studies demonstrate successful implementations across diverse industries, while our investment in independent third-party testing validates our performance claims. Regular factory audits and compliance certifications further reinforce our commitment to quality and reliability.

5. Why Choose Us?

• Heavyweight Fabric Specialization: Our expertise specifically in high-denier technical fabrics ensures unmatched product knowledge

• Military-Grade Quality: We deliver consistently superior quality that meets the most demanding specifications.

• Technical Innovation: Continuous R&D investment keeps our products at the forefront of material technology.

• Responsive Customization: We offer truly flexible OEM/ODM services with practical small-batch production from 500 meters.

• Global Compliance: Our materials meet international environmental and safety standards for worldwide distribution.

• Project Partnership: We function as an extension of your team, providing technical support from design through production.

6. OEM/ODM & Customization Support

We specialize in creating tailored solutions through our comprehensive customization capabilities. Our ODM services include custom fabric engineering, specialized coating formulations, and unique finishing treatments. We support custom color matching with digital color accuracy, specialized texture development, and brand-specific performance enhancements. Our flexible manufacturing approach accommodates small batch production from 500 meters, enabling market testing, limited editions, and specialized applications without large inventory commitments. We provide complete design-to-delivery support for proprietary fabric developments, ensuring your products maintain competitive advantage in the marketplace.

Applications:

500D nylon6.6 cordura is used in a variety of heavy-duty applications such as outdoor gear, pet accessories, and military/tactical gear.

Some common uses for this fabric include: Pet beds, luggage, bags, backpacks, tactical gear, horse blankets, wallets, gun cases, insulated food service carriers, footwear, and dog beds.

Specifications:

| Yarn: | 500D*500D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | Plain | Visual |

| Density(in): | W48*F35 | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.38MM | ASTM D 1777 |

| Width: | 58'' | ASTM D 3774 |

| Weight: | 6.48 oz/sq yd | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:185.5N, F: 181.5N | ISO 13937-3 |

| Tensile strength 1'': | W:1943N, F:1365N | ISO 13934-1 Strip method |

| Abrasion Resistance: | Over 1000cycles | ASTM D3884-09 |

Competitive Advantage:

Taiwan Weaving Quality

Factory direct sell price

High tensile

Super durability

Durable water repellent

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ