Nylon filter fabric is a durable and resilient material that has been used in many applications. This special fabric is crafted from nylon (a type of plastic), which is both strong and elastic. The efficiency and durability of nylon filter fabric make it very beneficial. This is a filter that can remove dirt and other unwanted particles from liquids and gases, evaluate even after having been put through their works. Find out more about what nylon filter fabric is, why it makes better filters and where the most interesting new uses are being developed.

What is Nylon Filter Fabric and How it Works? This fabric is made from super-thin nylon threads that are closely-knit into a protective barrier. The main function of this barrier is to prevent unwanted solid particles from passing while the liquids or gases pass out. There are various types of nylon filter fabric. And then there are the thickies, and the thinnies! The thinner the fabric, and larger the holes,the bigger particulates it lets through but with thicker fabrics covered in smaller holes thin dust particles will get captured on them.

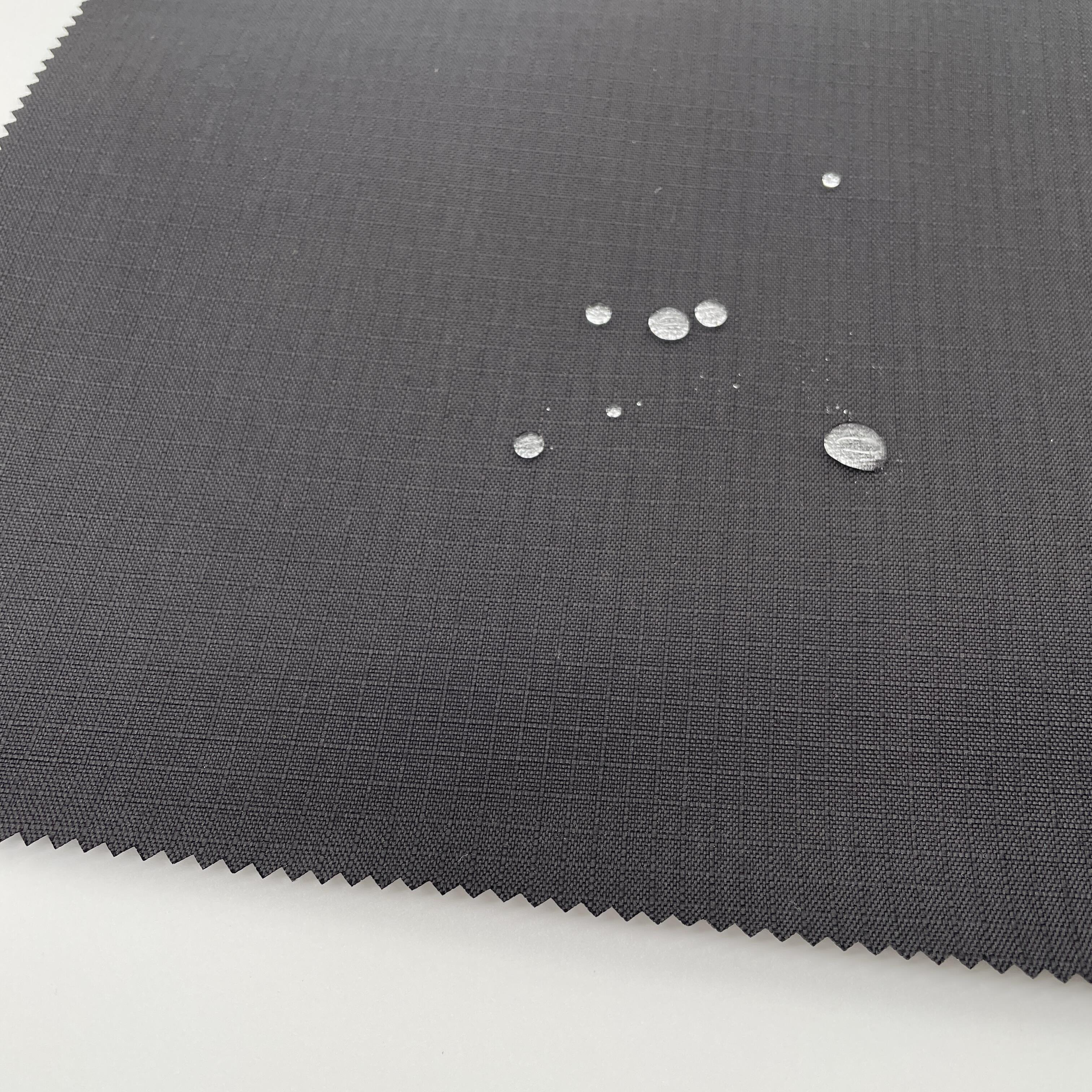

Nylon filter fabric features many qualities that make it ideal for a variety of uses and applications. For a start it is very strong and durable; something that can easily cope where other materials might fail in some tough conditions. Durability — This roof can also be used without the risk of having it deteriorated. The nylon filter fabric can also be used to safely and effectively filter out harmful, or corrosive liquids because it is resistant to chemicals. One other quality that is very crucial and helpful with nylon filter fabric: it's very versatile. This means it is easily malleable and can be used in various forms, which offers adaptability across an array of environments. Finally, cleaning it is also pretty easy and simplifies the hygiene factor which is a mandatory thing to do. It is perfect for the sterile environment because of its ease to maintain.

The nylon filter screen is applicable to industries including food and beverage, chemical processing, pharmaceuticals. Similarly, in the food and beverage manufacturing, nylon filter fabric is used to separate wastes from liquid substances such as milk and fruit juices. This means that any products are safe and suitable for human consumption. In chemical processing, the aiding in chemicals to lower down unwanted compounds resulting into high-quality product at end. In the medical field, nylon filter fabric is very important to enable production of pharmaceuticals in clean and sterile environment. This process also reduces the risk of contamination and ensures that the medicine is safe for use in patients.

Versatile and adaptableMuch as it turned out, the nylon mesh filter is versatile and can be used in a variety of fields beyond liquids or gases. For example, it could also be put to use in the clothing worn for protection from toxic materials. It can also function as a reinforcing material in other products, rendering them more robust and durable. Outside of our homes, nylon filter fabric is the material we interact with most frequently in air and water filtration systems — vital for extracting unwanted particulates from either airborne media that requires cleaning before final pressurization (the air part) or consumables which need elemental removal prior to delivery into a process stream. Should we go further in explaining the usefulness of this material?

Advances in technology are really helping to make and use nylon filter fabric better. In a recent development in the area of textile manufacturing, new ways have been introduced to manufacture nylon filter fabric very fast and more smoothly. Very cool, but a new line of thinking it to harness 3D printing technology and create bespoke filters for specific areas. This enables manufacturers to produce filters that exactly suits the needs of various sectors. This innovation: Smart fabrics Tiny sensors are integrated into these fabrics, and can tell how well the fabric is filtering things out -- actually changing filtration levels on their own. This development could be an efficient sieve for water filters in which minimum human effort is required.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all nylon filter fabric and also we have been working with our local certified 3rd party testing center who can give us fast, exact and certified testing reports. Our sales staff can give quick and precise responses to requests from customers. We also have a team for shipping that can offer solutions for shipping in case customers are having issues with shipping.

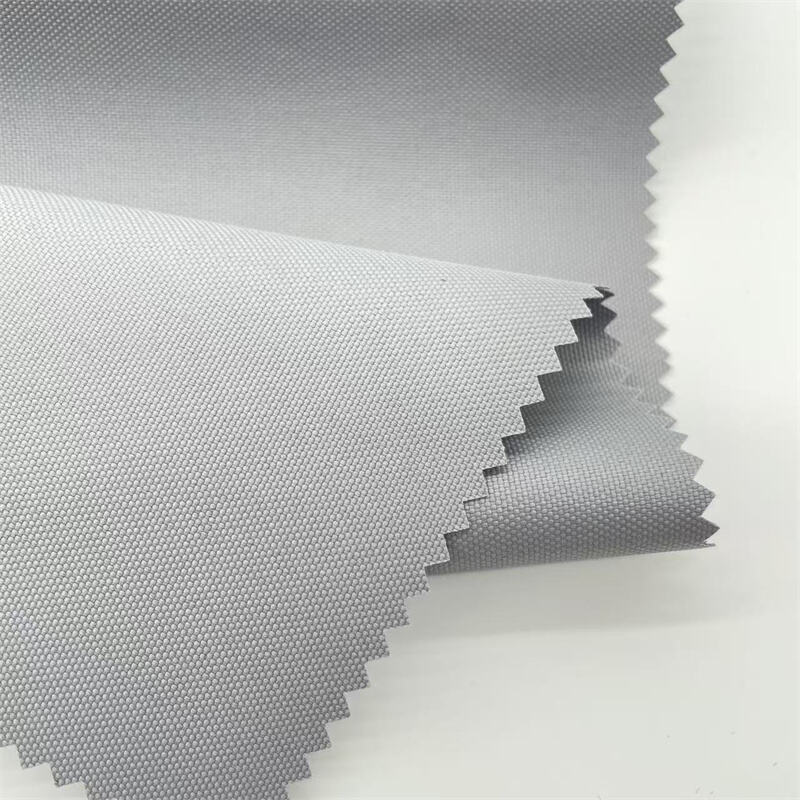

Suly Textile offers a wide range of nylon filter fabric which can be adapted to meet the needs of different customers. Suly Textile is involved in the manufacturing and selling of all kinds of chemical fabric and blended fabrics, including dyeing, coatings, bonding, and laminating. We are specialized in functional fabrics like tough Water repellent fabric, high water column and breathable fabrics, Anti-UV fabric, Anti-static fabric, Moisture absorbing and quick drying fabric flame retardant fabrics, anti-heat fabrics, printed fabrics, IFR fabrics, etc which all can meet or over meet the same fabric requirements. In addition, we offer low MOQ printing for printing. We offer a wide range of fabrics to choose from and provide a single-stop solution.

suly textile a professional fabric manufacturer that covers more than 20 000 sq m has four lines of pu coated lines these pu coated lines are all imported and can provide a better quality coating meanwhile we also have 2 lines of pvc coating lines which mostly produce outdoor fabrics bags tents and industrial using our technicians all have more than 10 years experience in the field of textile production and are able to provide superior products and services for quality control we are nylon filter fabric for our nylon fabrics we import dyes greige and finishing products from taiwan and then finish them in our facility

Our main product is Softshell fabric, Hard shell fabric RPET fabric Workwear fabric, bag fabric Down jacket fabric Aramid fabric Cordura Fabrics that are flame retardant and more. Our company also offers an nylon filter fabric service that allows us to weave to your specifications, like Crinkled dyeing and piece dyeing. We can also offer TPU/TPE coatings, anti-static, TPU milky/clear, flame retardant, high breathable, PA, black-out, brushed, PVC laminations, PU transfer etc.