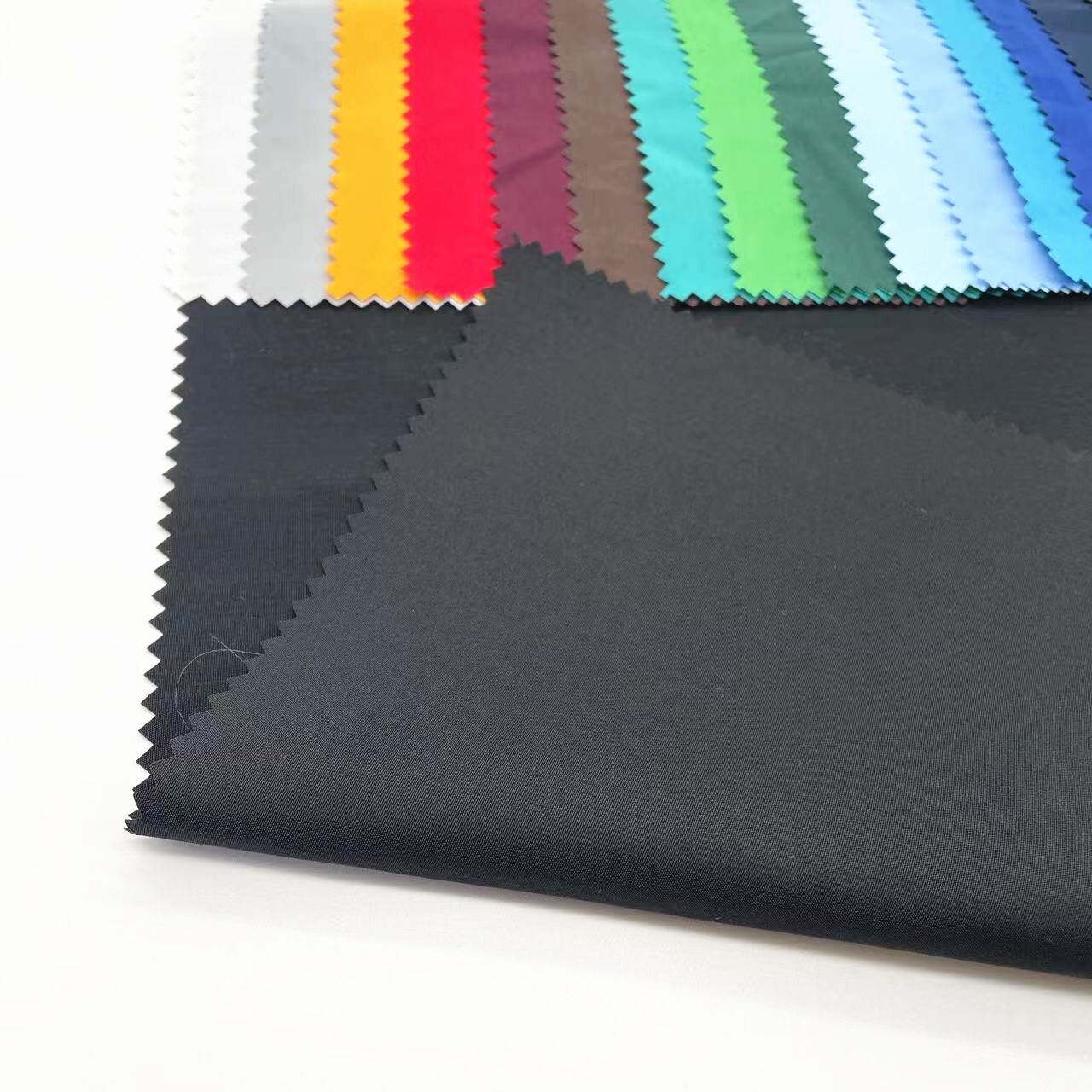

Weldable TPU coated 70D rip-stop nylon taffeta fabric Medical Inflatable Products

| Content: | Nylon |

| Coating: | TPU(thermoplastic polyurethane) |

| Country of origin: | China |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 100yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

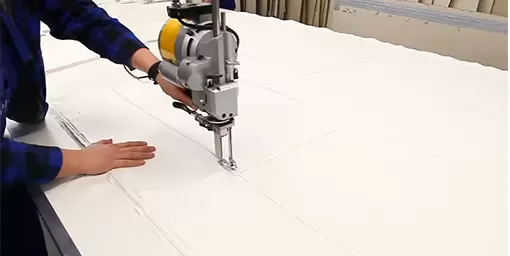

- Process flow

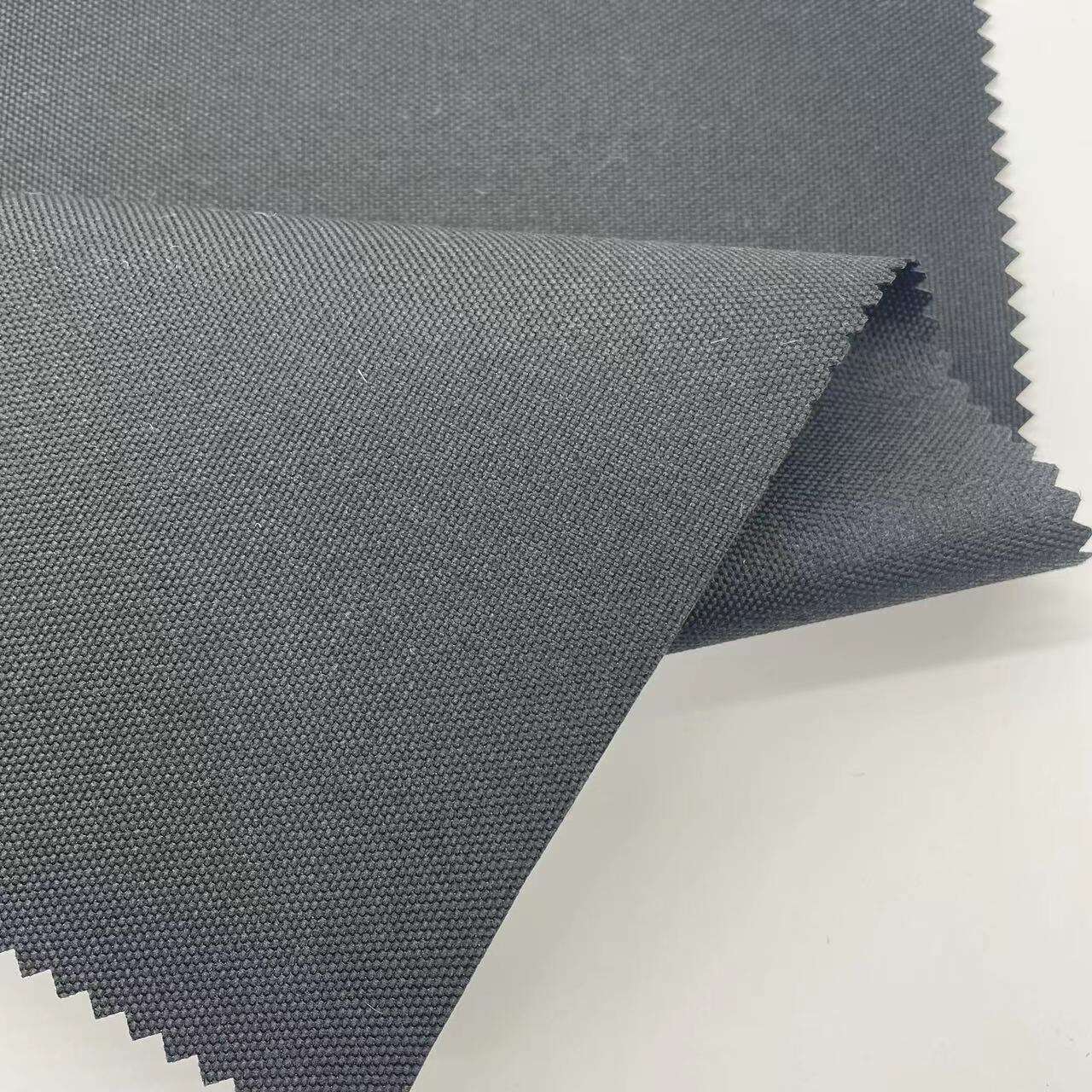

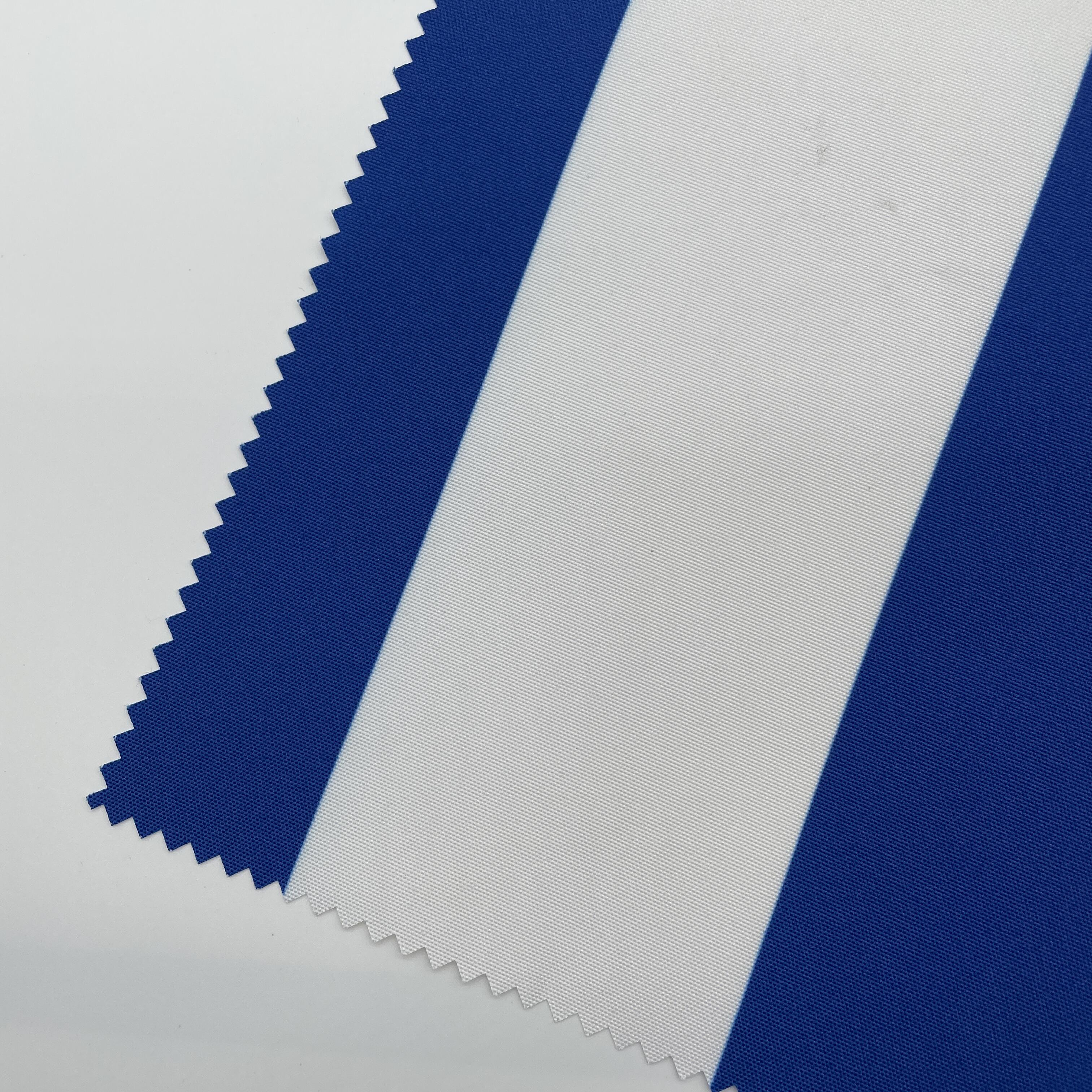

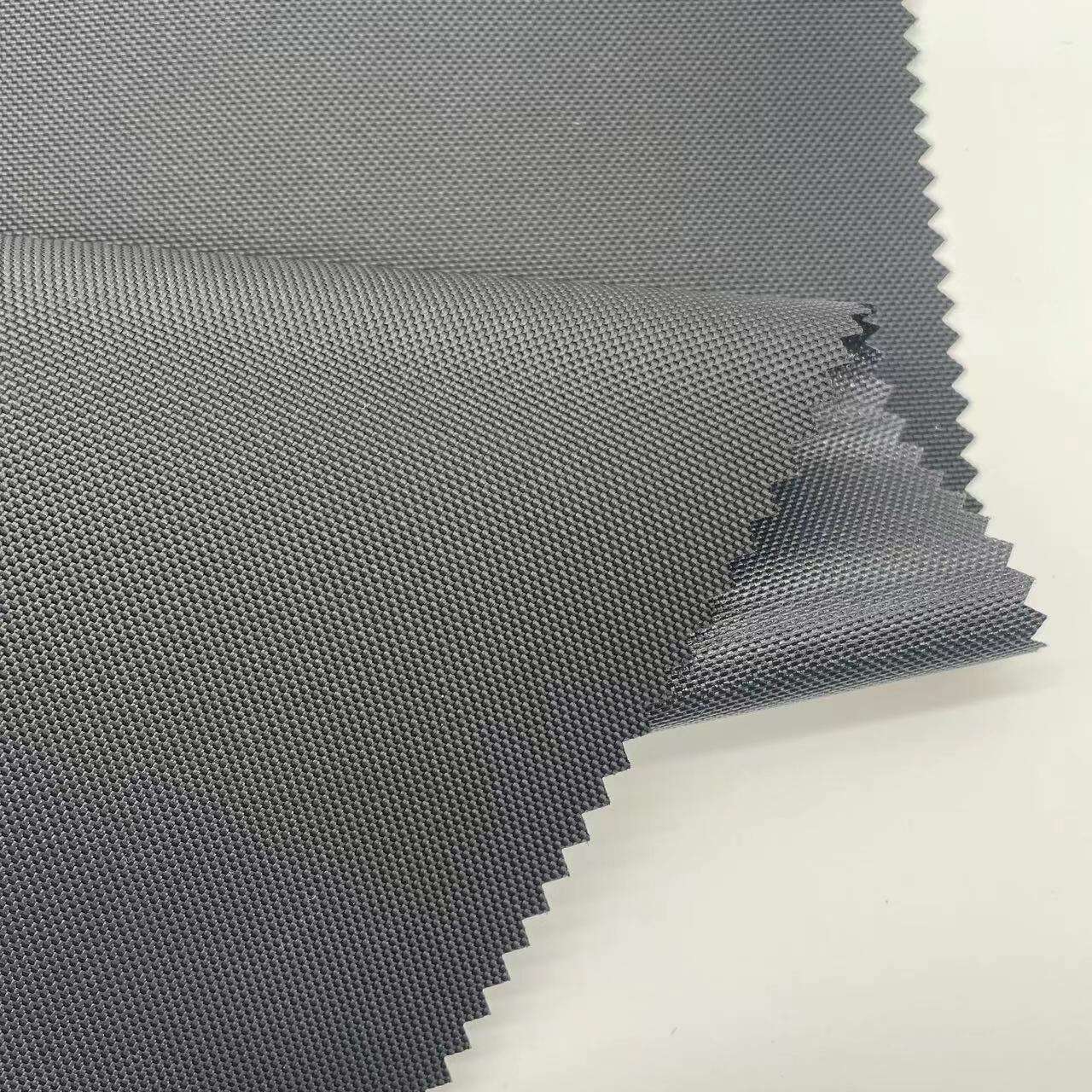

- Related products

- Inquiry

Parameter

This TPU Coated 70D Rip-stop Nylon fabric can be used for oxygen Bag; Blood Cuff; Air walker; Air Tourniquet; Reusable Pressure Infuser. Perfect when a reliably waterproof and airtight material is needed. TPU (Thermoplastic Polyurethane) is pretty similar to PVC but it is far more abrasion-resistant, tear-resistant, resistant to low temperature and aging. Can be heat sealed. It is also PFAS free.

Which iron do I use for heat-sealing?

We have used both the Jamara Pro Star iron and the Prolux Digital Iron. Or look at the Smaller Electric Iron when dealing with smaller seams and tight areas. Our fabric’s TPU coating is activated at roughly 220 degrees.

What is heat sealing?

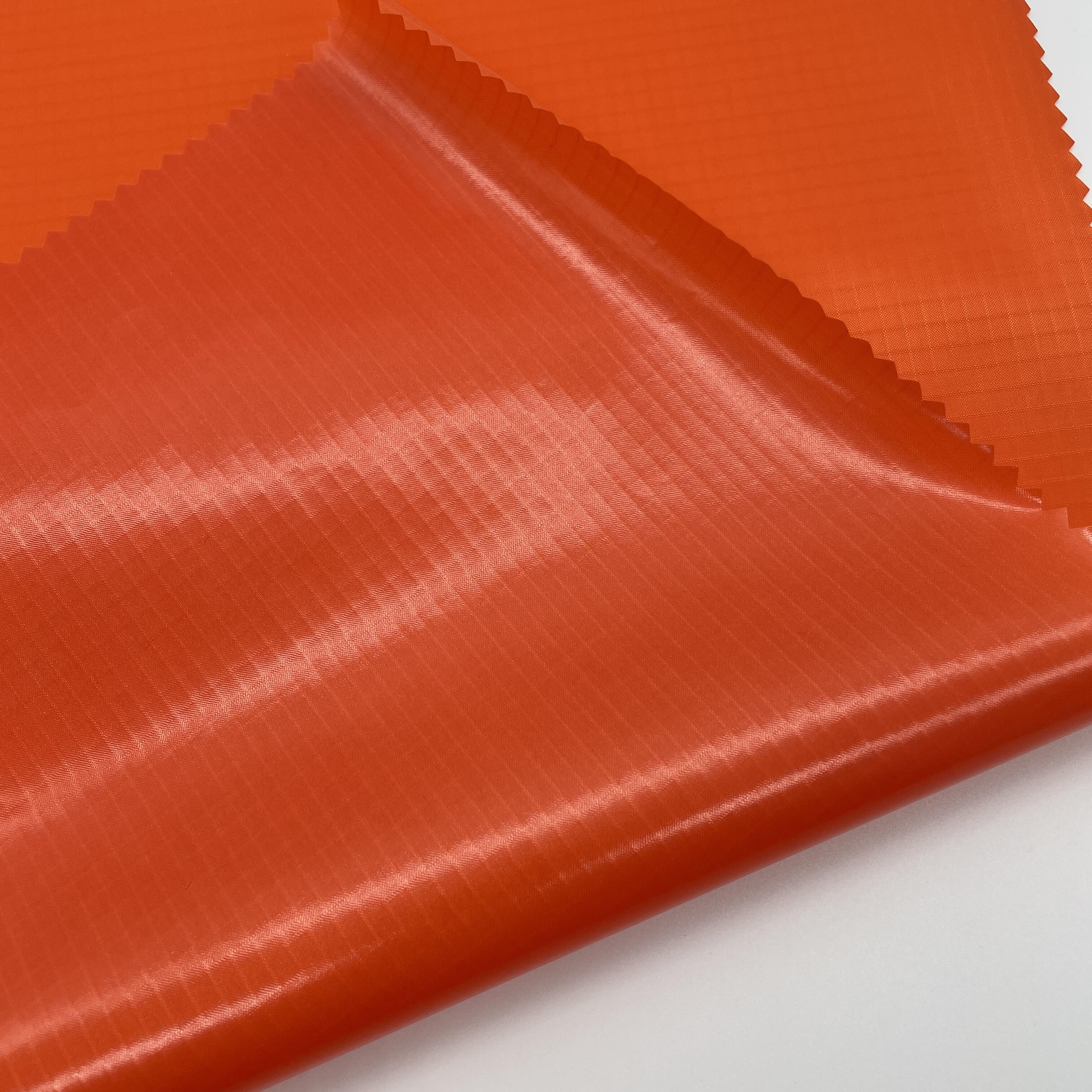

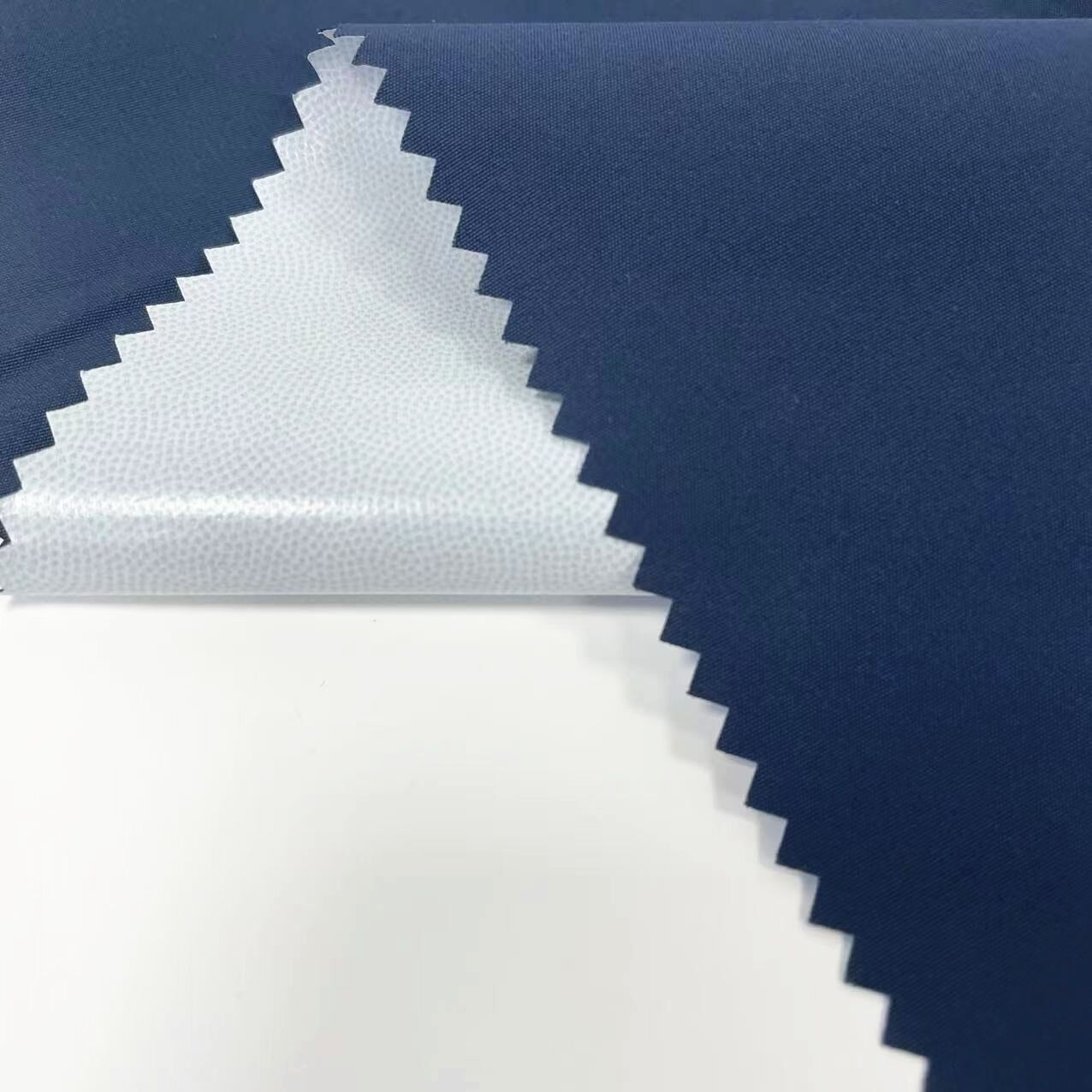

All our fabrics have a technical coating called thermoplastic polyurethane (TPU). This coating makes it possible to essentially stick the fabric together without having to mess around with glue! The TPU coating can be activated when heated with hot air or an iron.

For manufacturers of critical medical devices, material integrity is not just a specification—it is a imperative. Our Weldable TPU coated 70D rip-stop nylon taffeta fabric is meticulously engineered to serve as the foundational component for high-stakes medical inflatable products, including emergency splints, anti-shock garments, pressure mattresses, and rehabilitation equipment. This fabric combines the proven reliability of a rip-stop construction with the superior bonding capabilities of a precision thermoplastic polyurethane coating, ensuring unparalleled performance where it matters most.

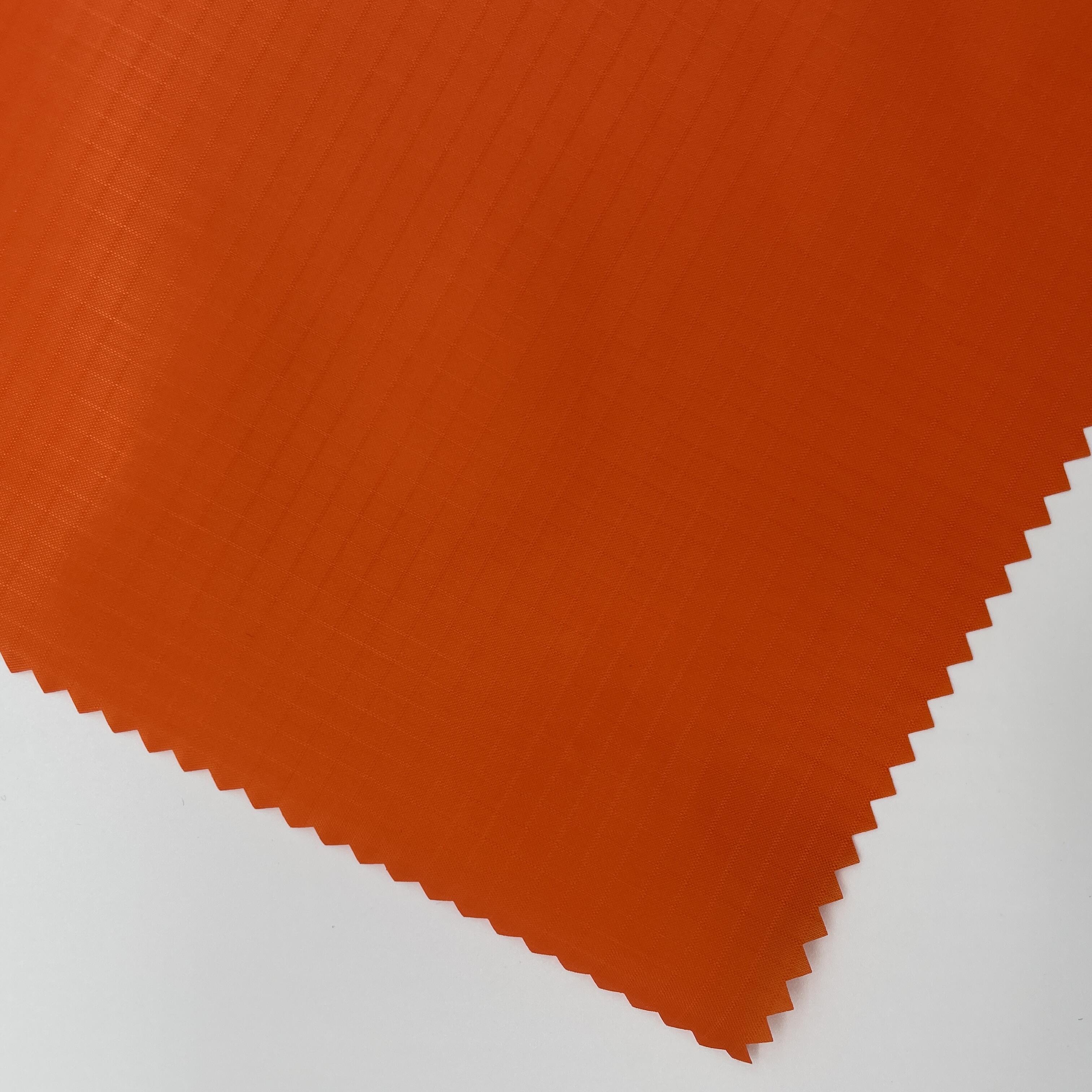

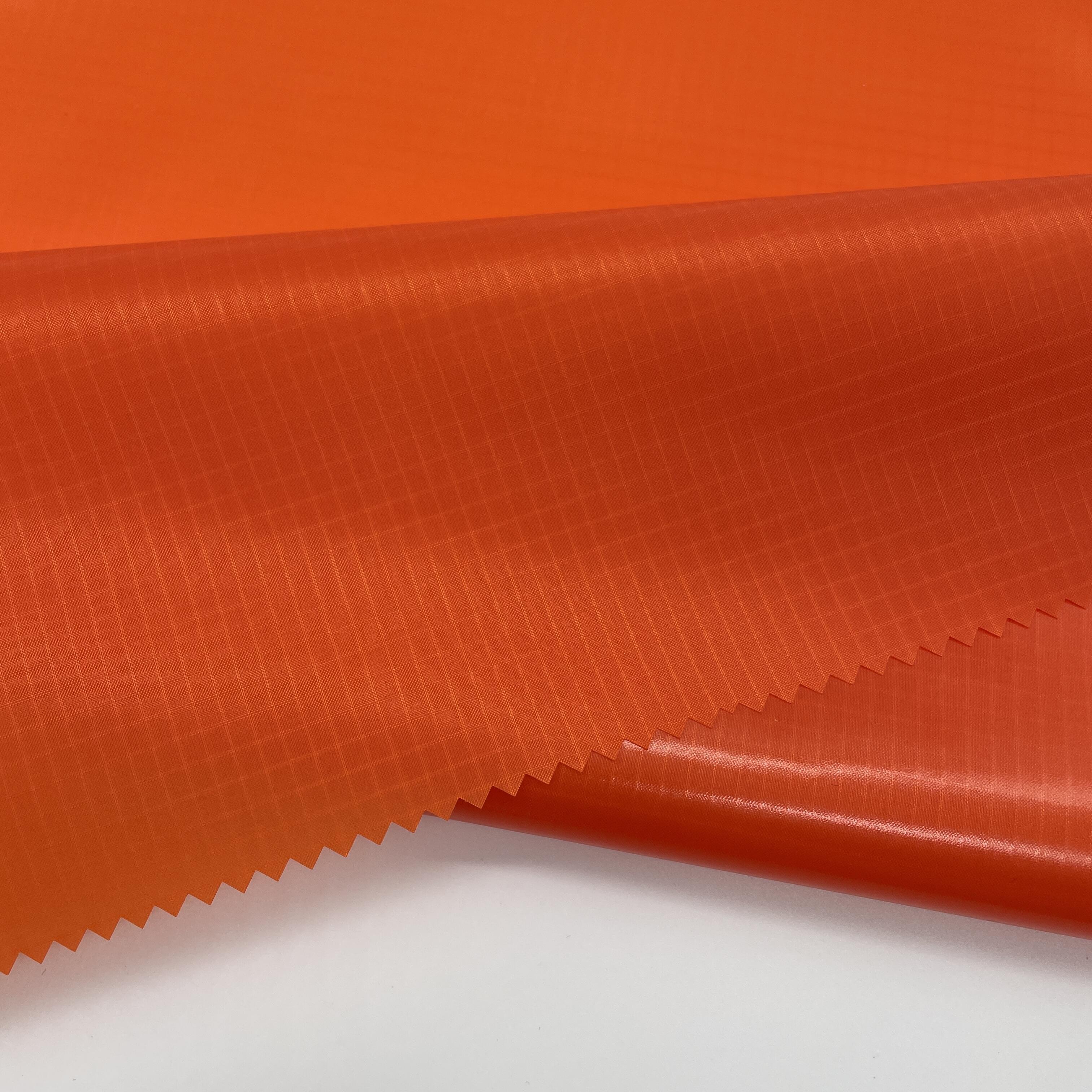

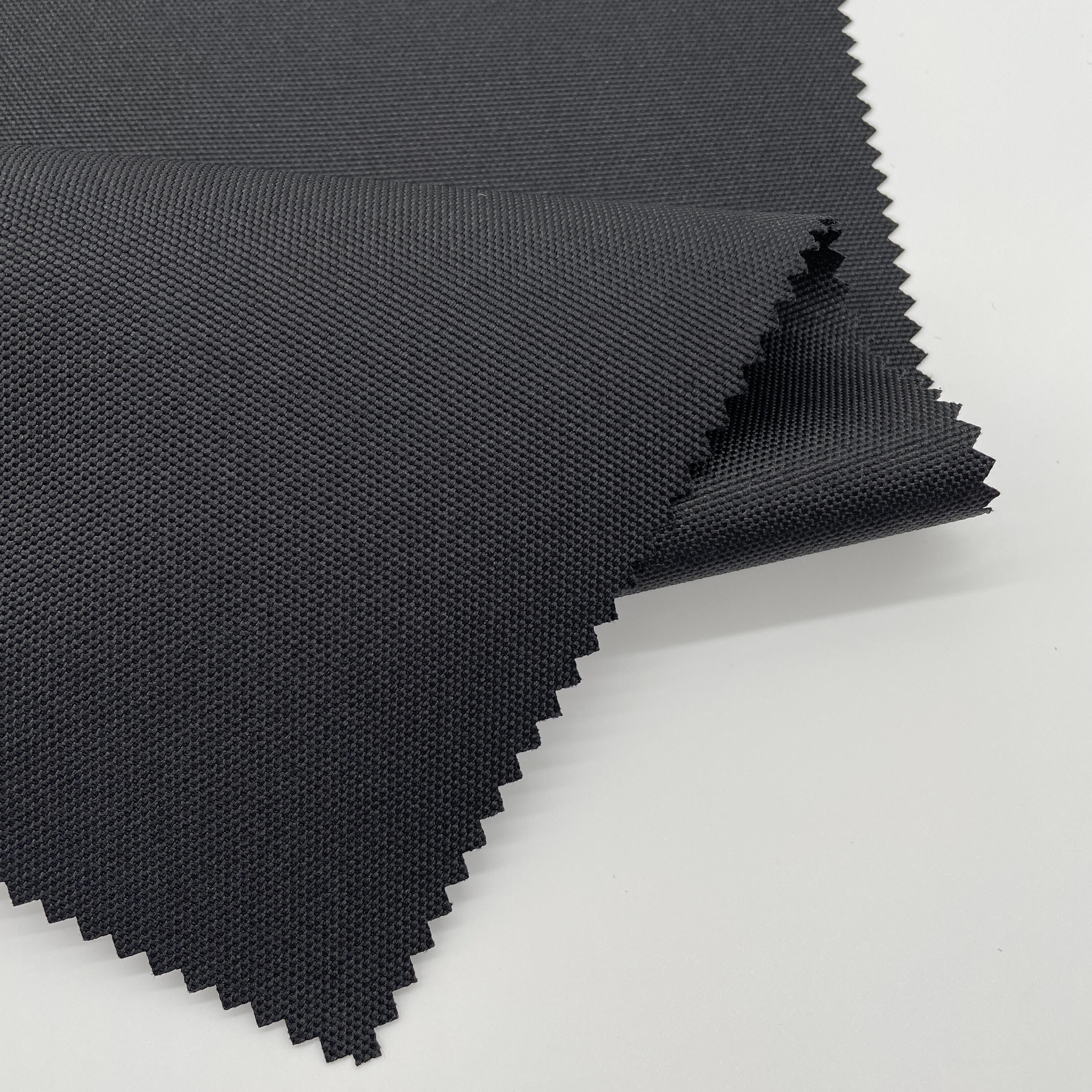

The exceptional durability of this material begins with its base substrate: a high-tenacity 70D rip-stop nylon taffeta fabric. The unique grid pattern inherent to the rip-stop weave effectively prevents tears and punctures from propagating, significantly enhancing the product's longevity and resistance to damage. This robust foundation is then uniformly laminated with a medical-grade, consistently formulated TPU coating. This specific coating is engineered for exceptional weldability, creating permanent, high-strength, and perfectly airtight seals when using RF (radio frequency) or heat welding techniques. The reliability of this TPU coated 70D rip-stop nylon taffeta fabric is what makes it an industry preferred choice for demanding medical inflatable products that must perform flawlessly under pressure.

Uncompromising Quality for Critical Applications:

We operate under a quality-first paradigm, understanding that your products directly impact patient care. Our manufacturing process is governed by strict ISO-compliant protocols, and our TPU coated 70D rip-stop nylon taffeta fabric undergoes a rigorous multi-point inspection regime. This includes tests for coating adhesion strength, hydrostatic pressure resistance, air permeability, and biocompatibility (where required). We provide full traceability and detailed test reports from independent laboratories (such as SGS), giving you the documented evidence needed for regulatory submissions and your own quality assurance.

A Collaborative and Flexible Partnership:

Your success is our mission. Our service process is designed for seamless integration into your development cycle. From initial technical consultation and providing material data sheets to sharing expert welding guidelines and conducting pre-production sample approvals, we act as an extension of your R&D team. We empower innovation by offering a low Minimum Order Quantity (MOQ) of 1000 meters, allowing you to undertake prototyping and small-batch production runs without excessive inventory commitment. This flexibility, combined with our technical support, ensures a efficient and risk-mitigated path from concept to final product.

When failure is not an option, specify the material trusted by leading medical device manufacturers. Choose our Weldable TPU coated 70D rip-stop nylon taffeta fabric for your next project. Contact us to request samples and technical documentation.

Applications:

This TPU inflatable fabric can be widely used in inflatable mattresses, air cushions, air cushions, air cushions, tents, waterproof bags, drying bags, storage bags, waterproof bags, drying bags, outdoor backpacks, map bags, Ipad bags, phone bags, basins , Buckets, water bags, inflatable tents, airbags, inflatable helium remote control airships, hot air balloons, etc.

The first application of TPU is as an environmentally friendly substitute for PVC, so the TPU waterproof fabric can be used wherever PVC fabrics are used.

Specifications:

| Yarn: | 70D*70D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

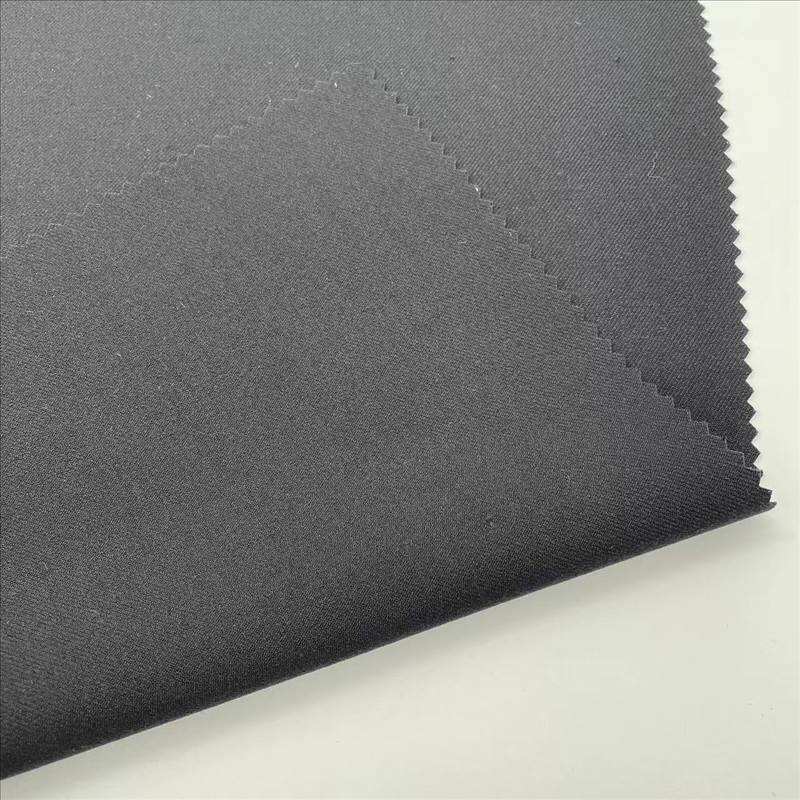

| Weave: | Rip-stop | Visual |

| Density(in): | W115*F88 | ISO 7211/2 |

| Finishing: | TPU coating | Visual |

| Thickness: | 0.12MM | ASTM D 1777 |

| Width: | 56/57'' | ASTM D 3774 |

| Weight: | 170GSM | ASTM D 3776 |

| Tear strength: | W:3.2LBF, F: 2.4LBF | ASTM D1424 |

| Tensile strength 1'': | W:248LBF, F:212LBF | ASTM D5034-21 Grab test |

| Hydrostatic Pressure: | 10000MM | AATCC TM127 |

Competitive Advantage:

Weldable

Factory direct sell price

Durable abrasion

Heat sealable

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ