Printing on nylon is a fun and really interesting way to put funky patterns onto pieces for clothing, bags or anything else made from this specific material. The material is compatible with printing and this alone justifies a wide use of nylon fabric. This is because it is a hardy and durable material that will wear for years to come — if you use them properly. Second, it has a very light weight so that we can wear or carry. Nylon fabric repels water, making it excellent for items that might get wet. In this post, we will look at everything to know about nylon and how you can print on it with the most suitable way along with some helpful tips for outstanding results.

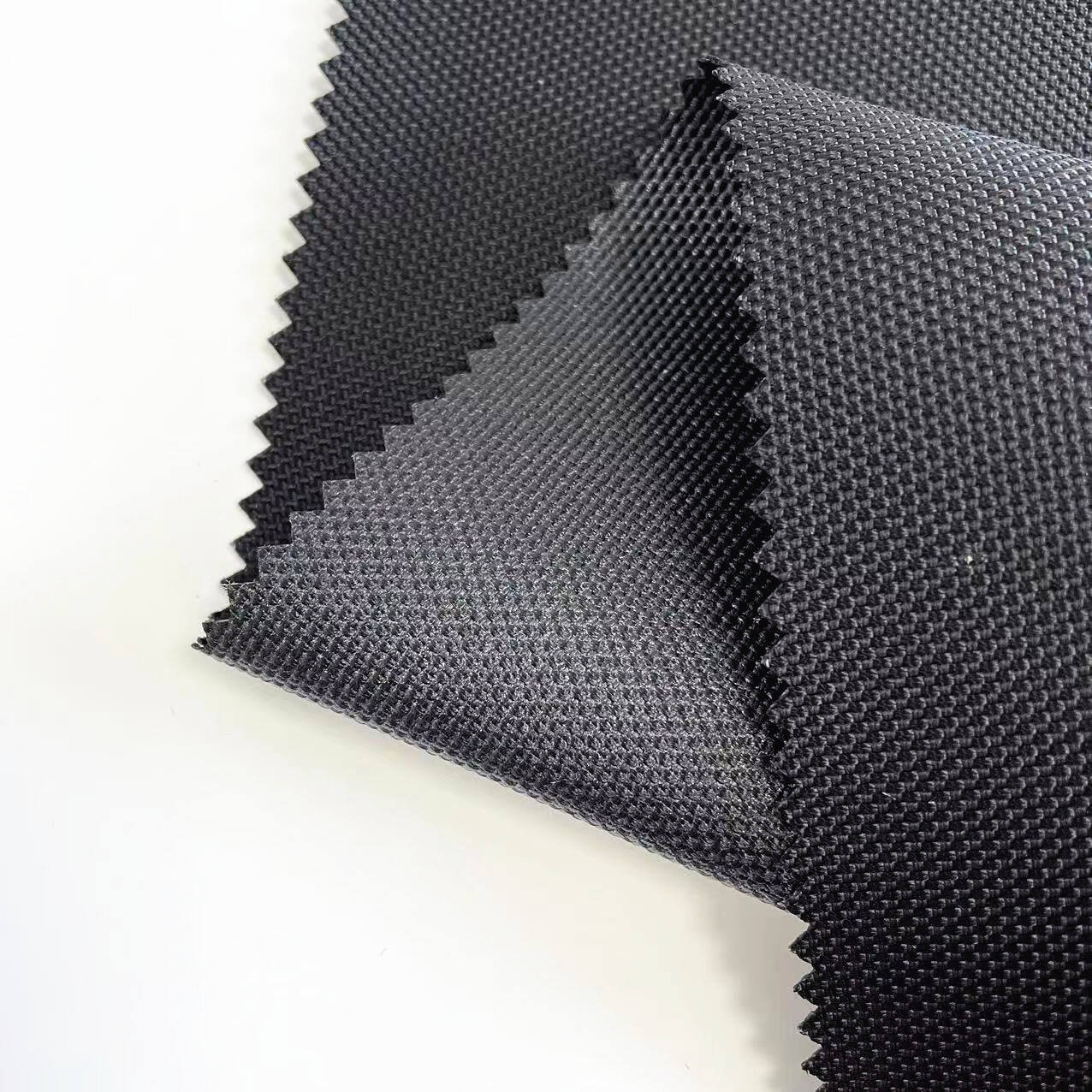

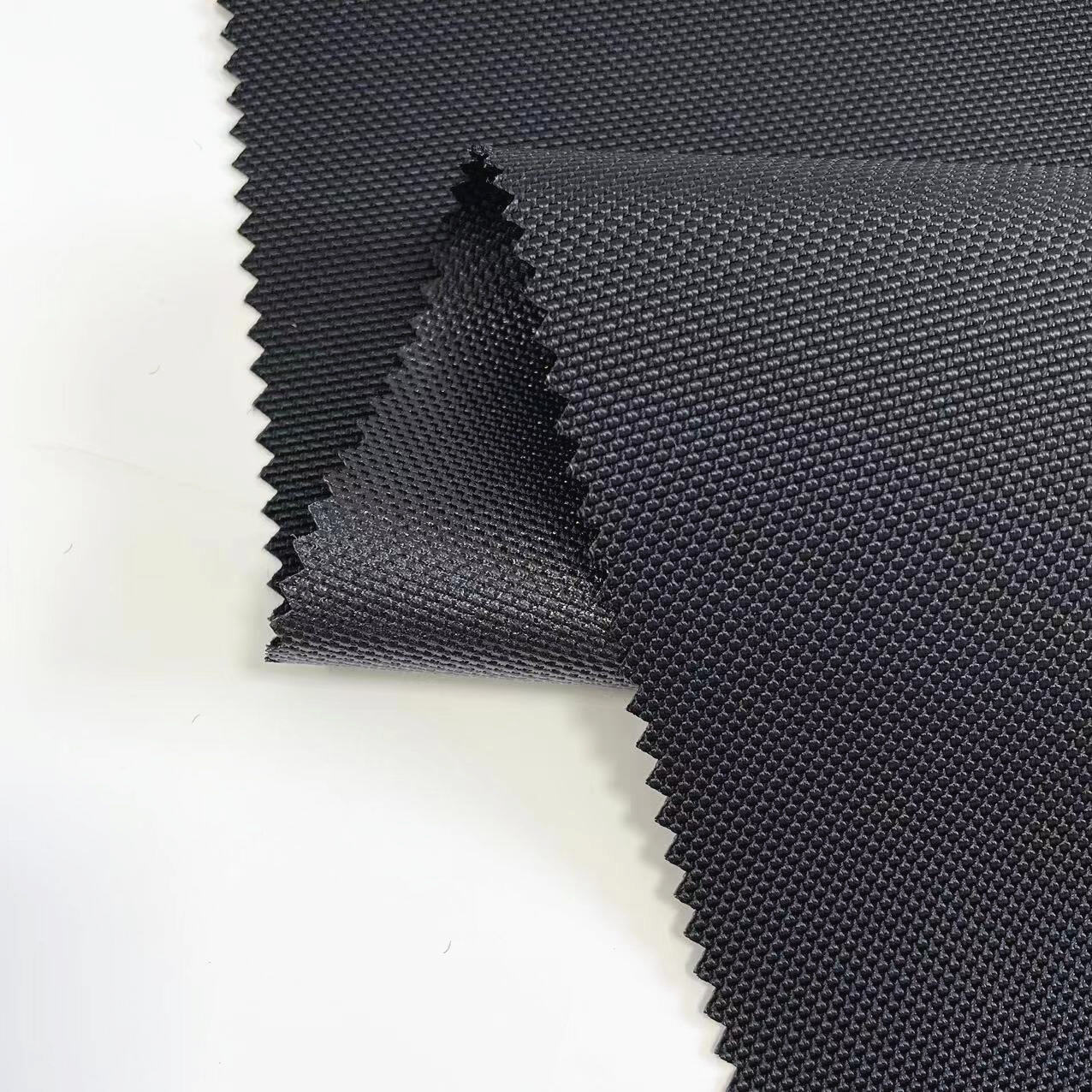

One of the best features are about nylon fabric which has become a great necessity for printing industries. Due to its strength-to-weight ratio, nylon is great. It can hold up to a lot of damage, which is why you see it used in bags and clothing. One very cool thing about nylon is that it absorbs color really well, so the prints are super bold and vibrant. Really good for those who loves to make a stand out and playful designs.

Being resistive to water is another key benefit of nylon fabric. This means it can be dried soon and does not get spoilt easily by water (0). This makes nylon great for products such as swimwear, outdoor gear or anything you plan on getting wet. Thus, if you have the intent of creating something that should look good and last under any weather condition then nylon fabric is your go-to guy.

If we print on nylon fabric then a particular process is followed so that the design will not peel off and looks good. It is essential that you wash the fabric since it could be covered in dirt, dust or even oil. This is also necessary as it helps the ink in printing to get a grip. Stretch the fabric over a frame or secure it against a flat surface to ensure that your prints remain in place even when you print with them after washing.

Once you need to do this put together a sketch on paper, or onto your computer. This design Is then placed onto the nylon fabric utilizing a certain printing ink transfer practice. Screen printing, dye sublimation and digital prints are some common examples of the methods mainly associated with this practice. Some of these methods have their own strengths and cater more naturally to particular types of designs. You print the fabric: Heat to ensure proper penetration of ink and longevity of print.

This also greatly impacts the final results: excellent ink and equipment. High-quality inks are essential for creating vibrant, long-lasting prints. Also, proper equipment is needed to make sure that the ink gets precisely placed on fabric. Lastly, observe how they show the drying and curing process after printing. This part right here is super important as it will alter how your fabric takes the print. A good dry and cure helps the print stay vibrant longer without fading or cracking as well.

This kind of fabric is very useful in many areas due to the printed nylon fabric available. It has become common in swimwear, activewear and outddoor clothing within the fashion industry. Things like the durability and water resistance of nylon. It is also a favorite staple for the home decor, where printed nylon manufactured in North America serves as curtains, bedding and upholstery furniture pieces.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our local certified 3rd party testing center who can give us fast, exact and certified testing reports. Our own sales team can provide fast and accurate responses to the customer's needs. Additionally, we have a team for shipping who can printing on nylon fabric excellent solutions for shipping in case customers are having issues with shipping.

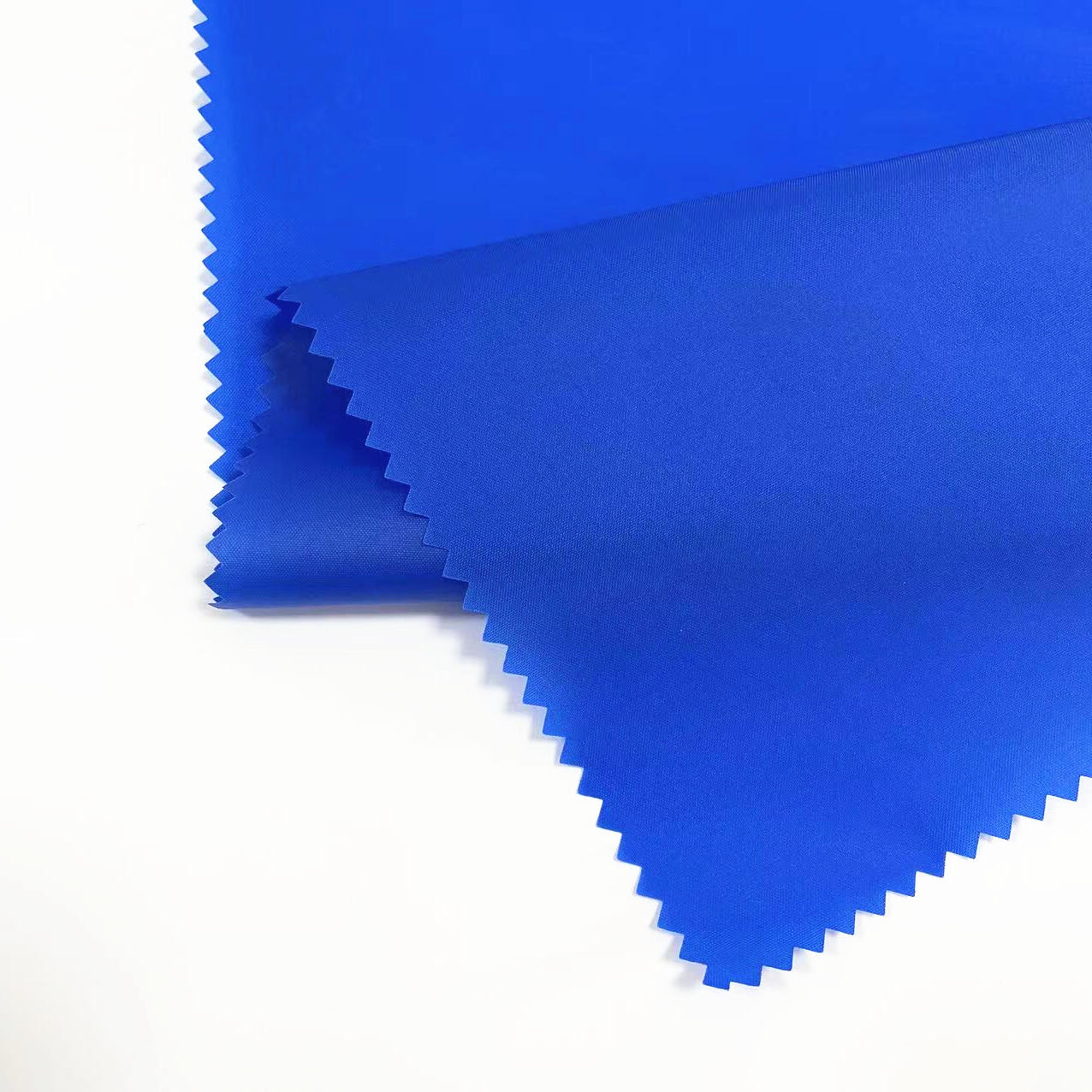

Our company offers an OEM service that can weave precisely to meet your needs such as Crinkled dyeing or Piece dyeing Water repellent, printing, Water column, Teflon finish, printing on nylon fabric, TPE coating Anti-static, Downproof, PU milky/clear coating flame retardant, high breathable, PA, Black-out, Brushed, PVC lamination, PU transfer, Moisture absorption and quick drying, etc. In addition, our company offers the OEM service, which will weave specifically according to your needs, including Crinkled dyeing water repellent, printing water column, Teflon finishing, TPU coating, TPE coating, Down proof Anti-static, PU milky/clear coating, Flame retardant coating, High breathable coating, PA coating Cire, black-out coat embossed, brushed, PVC lamination and PU transfer coating anti-UV, moisture absorbing and quick drying, etc. Our product is widely utilized to make hiking jackets, skiing jackets, sport jackets, down-proof camping jackets, outdoor camping, children sportwear, women dress, etc.

suly textile a professional fabric manufacturer that covers more than 20 000 sq m has four lines of pu coated lines these pu coated lines are all imported and can provide a better quality coating meanwhile we also have 2 lines of pvc coating lines which mostly produce outdoor fabrics bags tents and industrial using our technicians all have more than 10 years experience in the field of textile production and are able to provide superior products and services for quality control we are printing on nylon fabric for our nylon fabrics we import dyes greige and finishing products from taiwan and then finish them in our facility

Suly Textile can provide various types of custom-made fabrics that can meet different customers' requirements. Suly Textile is involved in the manufacturing and selling of all types of chemical fabric and blended fabrics for coating,printing on nylon fabric, bonding and laminating. We are specialized in functional fabrics such as strong water repellent fabric as well as high-water column fabric. Additionally, we provide anti-static, anti-UV, moisture absorption, quick drying, anti-heat, flame retardant printed IFR and printed. We also allow printing at a lower MOQ. We provide a broad range of fabric options and offer a complete solution.