Two kinds of man-made fibers, nylon and polyester are produced these days for uses in numerous items from clothes to bags. Many kinds of materials are popular because they have various qualities that make them useful. Nylon is made from oil which are natural resources whereas polyester is a type of plastic that was created through different kinds or chemical processes. If you touch both the materials, polyester will have a smooth and soft feel on your skin. In comparison, nylon is much rougher to the touch. One really cool thing about nylon is that it is super stretchy and bounces back like a champ, where polyester does not wrinkle very well. This results in polyester clothing that looks prim and proper for much longer without requiring too vigorous an ironing.

Both nylon and polyester have good as well as bad qualities. For instance, because nylon is fairly strong and wears well, it makes sense to use for rough made items like backpacks or outdoor gear. This is an ideal mattress protector for people who are frequently washing theirs, because it dries so quickly and doesnt need a tumble dry to be used- which cant be said w the waterproof protectors. But since this material is made up of nylon, it lacks breathability. Which in turn, makes it not that breathable, and this is why sometimes during hot days you might even sweat to death. Polyester, on the other hand is thin and breathable which allows for air breeze over it that makes it a great choice in summer when you want to keep cool. Polyester is also generally lower in cost than nylon which can be a plus to those that maybe looking save some money. That being said, if you are making something heavy-duty (like a tent), this may not be the best fabric since polyester is less strong than nylon.

While nylon and polyester are commonly found in clothing supply chains, they take varying forms. Nylon is widely used in such familiar objects as outdoor gear, swimsuits and even stockings because of its stretchiness (2-3 times better resistance than that of wool) and durability. It can also be combined with other materials like cotton or wool to generate sturdier fabrics which have the best attributes of both. Polyester is mainly used for t-shirts, sportswear; gym shorts and other casual clothing. Interestingly, it is also a good choice for fabric that helps in sweat management by drawing moisture away from your body.

While nylon and polyester are incredibly helpful there is a definite environmental downside to manufacturing these materials and having them used. Both synthetic fibers come from petroleum, a nonrenewable resource. The energy working to come up with artificial fibers contributes a lot of vitality to the process and is also emitting noxious gases which can cause polluting of. Additionally, when we launder our nylon and polyester clothes little plastic shards of fabric can snap away from the clothing to pass down through waterways into rivers and seas lines creating hazard for marine life as well environment. That is the primary worry for me, as well as many others who consider ourselves to be protecting our planet.

Nylon and polyester clothes, in particular, can last a very long time if properly care for. And a major tip would be to NOT put these in the dryer because of how high heat can melt or ruin their shape. So these are like best hang dry to take or preserve the original shape of them. When washing these fabrics, they can only be washed in a gentle cycle and with very mild soap to avoid breakdown of the fibers. Avoid using fabric softeners too, as these can make the fibres go limp over time. In the end, hang your nylon and polyester clothing in a cool environment as to not get mildewed or musty.

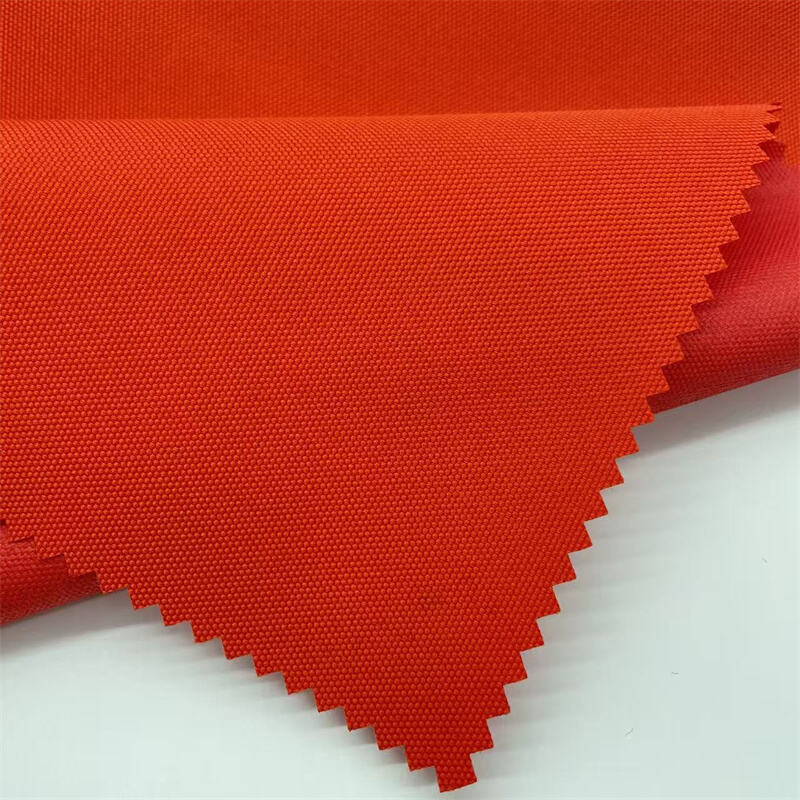

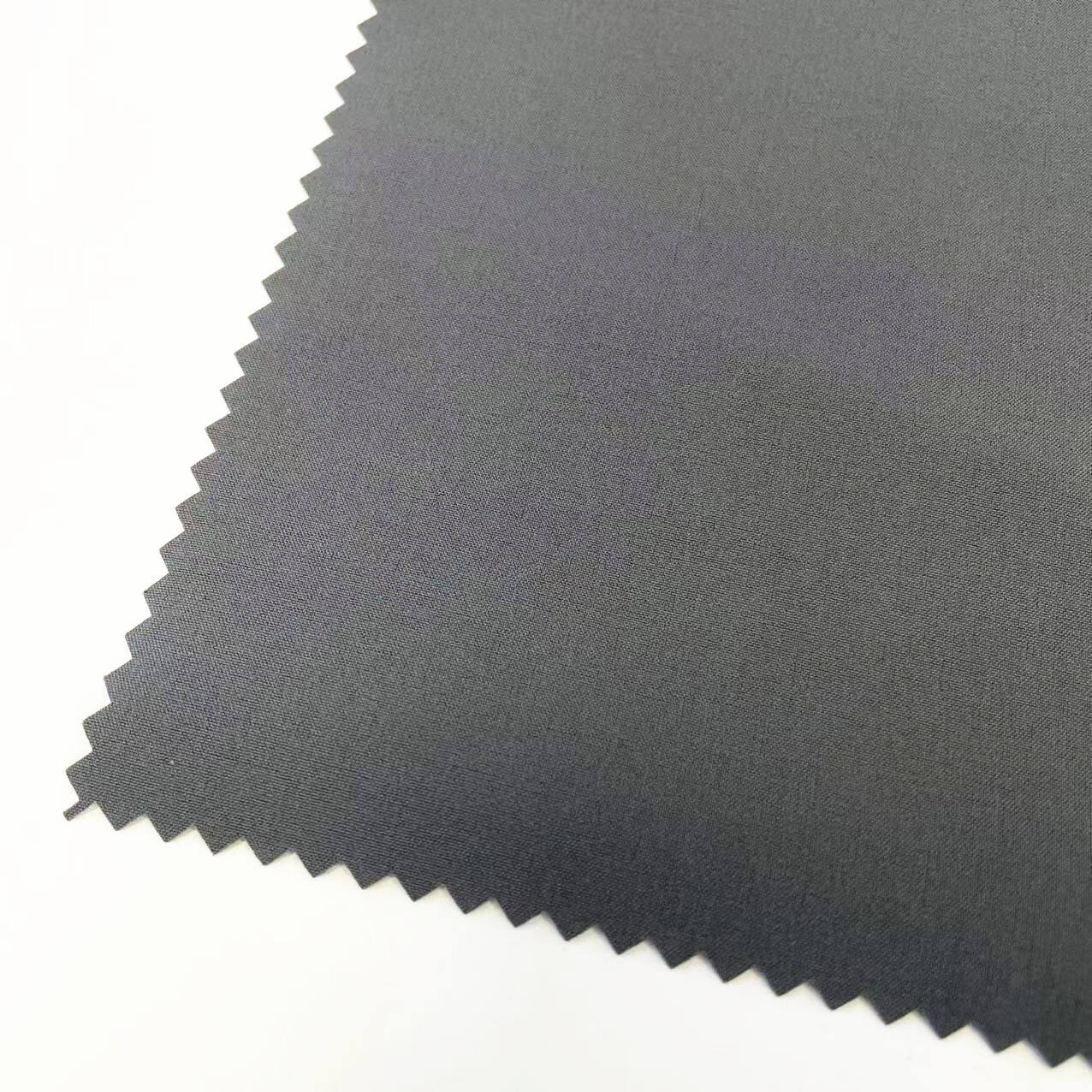

Suly Textile offers a wide range of nylon of polyester which can be adapted to meet the needs of different customers. Suly Textile is involved in the manufacturing and selling of all kinds of chemical fabric and blended fabrics, including dyeing, coatings, bonding, and laminating. We are specialized in functional fabrics like tough Water repellent fabric, high water column and breathable fabrics, Anti-UV fabric, Anti-static fabric, Moisture absorbing and quick drying fabric flame retardant fabrics, anti-heat fabrics, printed fabrics, IFR fabrics, etc which all can meet or over meet the same fabric requirements. In addition, we offer low MOQ printing for printing. We offer a wide range of fabrics to choose from and provide a single-stop solution.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our nylon of polyester 3rd party testing center who can give us fast, exact and certified testing reports. Our own sales team can respond quickly and accurately to the customer's needs. However, if a client has difficult for shipping, we also have our own shipping team that can provide a suitable solution for shipping.

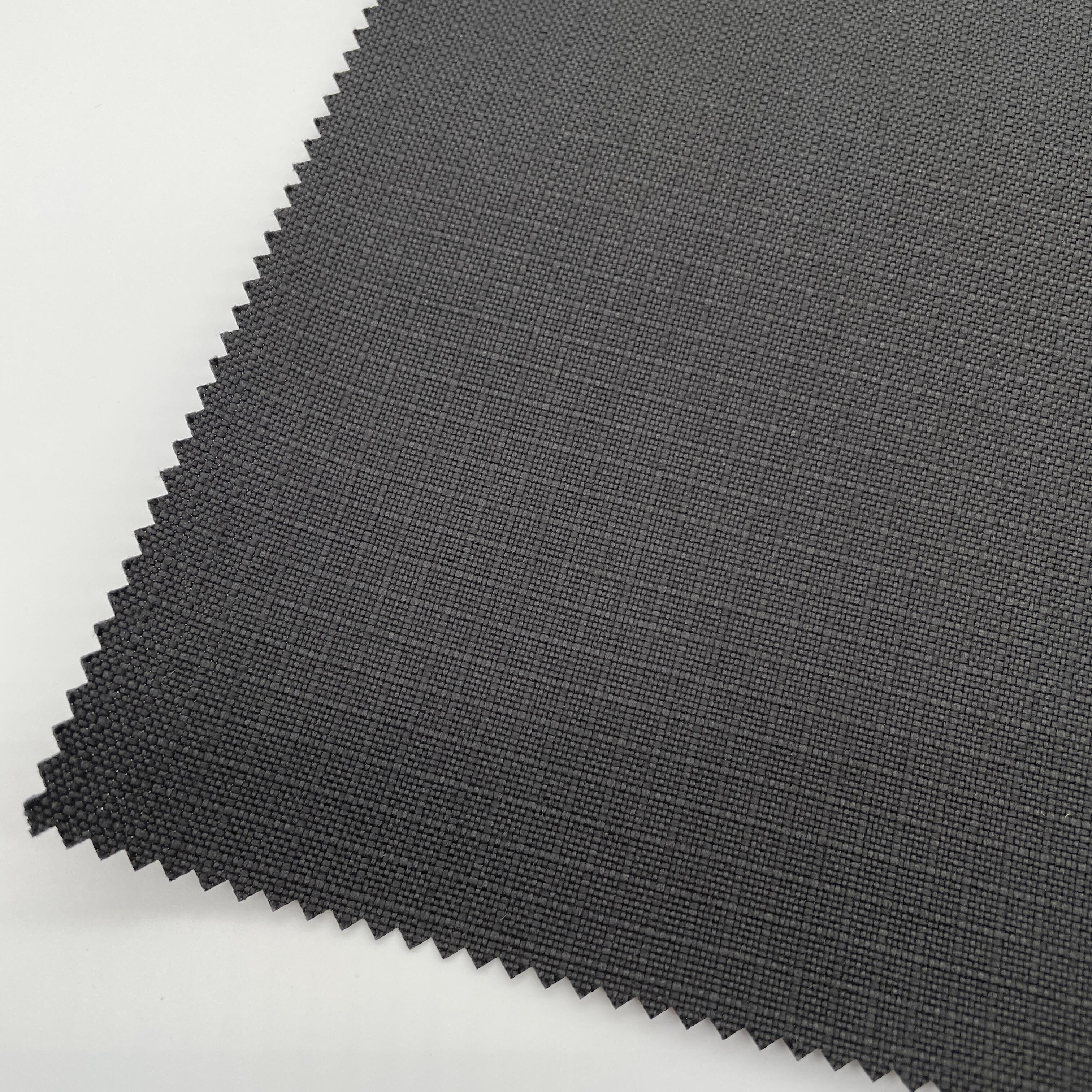

The main product of the company is Softshell fabric, Hard shell fabric nylon of polyester fabric, Workwear fabric, Bag fabric Fabric for down jackets, Aramid fabric, Cordura Fabrics that are flame retardant, etc. Our company also provides an OEM service that allows us to weave in accordance with your requirements, such as piece dyeing or crinkled dyeing. We can also offer TPU/TPE coatings and anti-static materials liquid/clear TPU, flame retardant, high-breathable, PA, black-out brush, PVC laminations, PU transfer, and many more.

Suly Textile, a professional fabric producer with a total of 20,000 sqm, has four lines of PU coated lines. The PU coated lines come from the United States and provide better quality coating. In addition, we have nylon of polyester of PVC coating lines which mainly produce outdoor fabrics bags, tents and industrial use. All of our technicians have more than 10 years experience in the field of textile production and are able to provide more efficient quality control and solutions. We are known for our nylon fabrics. We import dyes, greige and finishing products from Taiwan and finish them in our manufacturing facility.