Polymerisation Reactant"(Source: thefabriccorp.com) The small building blocks contained in nylon(Nylon is one kind of a fabric), these are actually called as polymers. These polymers are akin to inter connected long chains. This cool material was actually invented in a lab by a man named Wallace Carothersway back in the 1930s. He was employed by a company called DuPont and his task involved finding novel methods with which to create plastic. But one day he was experimenting with something and discovered how to make an incredibly tough, stretchy material. This incredible new substance would have many applications, such as toothbrush bristles and hosiery (a type of clothing women like to wear).

So, how is nylon made? So, nylon is made by combining different kinds of chemicals and heating them. When heated it turns into these chemicals to a liquid that polymer solution. And this magic juice can then be converted into powerful fibers. The manner in which these fibers can be woven or otherwise placed together will produce a strong and resilient structure, much like trying to bend papyrus without breaking it.

The parts are molecules, and these small pieces give nylon much of its strength. These long chains of molecules are what make up the polymers. That specific configuration turns nylon into a uniquely strong and flexible material. Chains is a term loosely banded about by scientists that are just control nuts like us. In this way, they can produce stronger or more elastic nylon as required.

There are many advantages rather than disadvantages in the use of plant-based nylon. For example, it can help us to minimize our reliance of oil.Oil is the finite source [1]. It also helps to reduce the pollution that we create in nylon production. Furthermore, making things with plant-based materials is simply better for the Earth since it consumes less of our resources, thus more sustainable in the long term.

Biotechnological processes offer one futuristic possibility to create nylon that is kinder to the environment. Called biological synthesis, in this process scientists enlist the help of living organisms (such as bacteria) to create those chemicals that are required for nylon manufacture. This solution is less costly to resources and waste, so it helps preserve our planet.

Back in its early days, nylon was primarily used for the military. It was used to create parachutes, ropes and other important items that soldiers required. With time passed, nylon gains acclaim in daily wear. These days we have found many different ways to use nylon, for example backpacks and jackets but not even underwear because everyone is wearing it.

Of course, the way we manufacture nylon has also changed a great deal over all those years. In today, there are plenty more eco-friendly types of nylon that can be produced as well. Indeed, nylon is being used to make even stronger clothing all the time; newer formulations of this fabric are able to withstand more abrasion maintaining their appearance until several washes down.

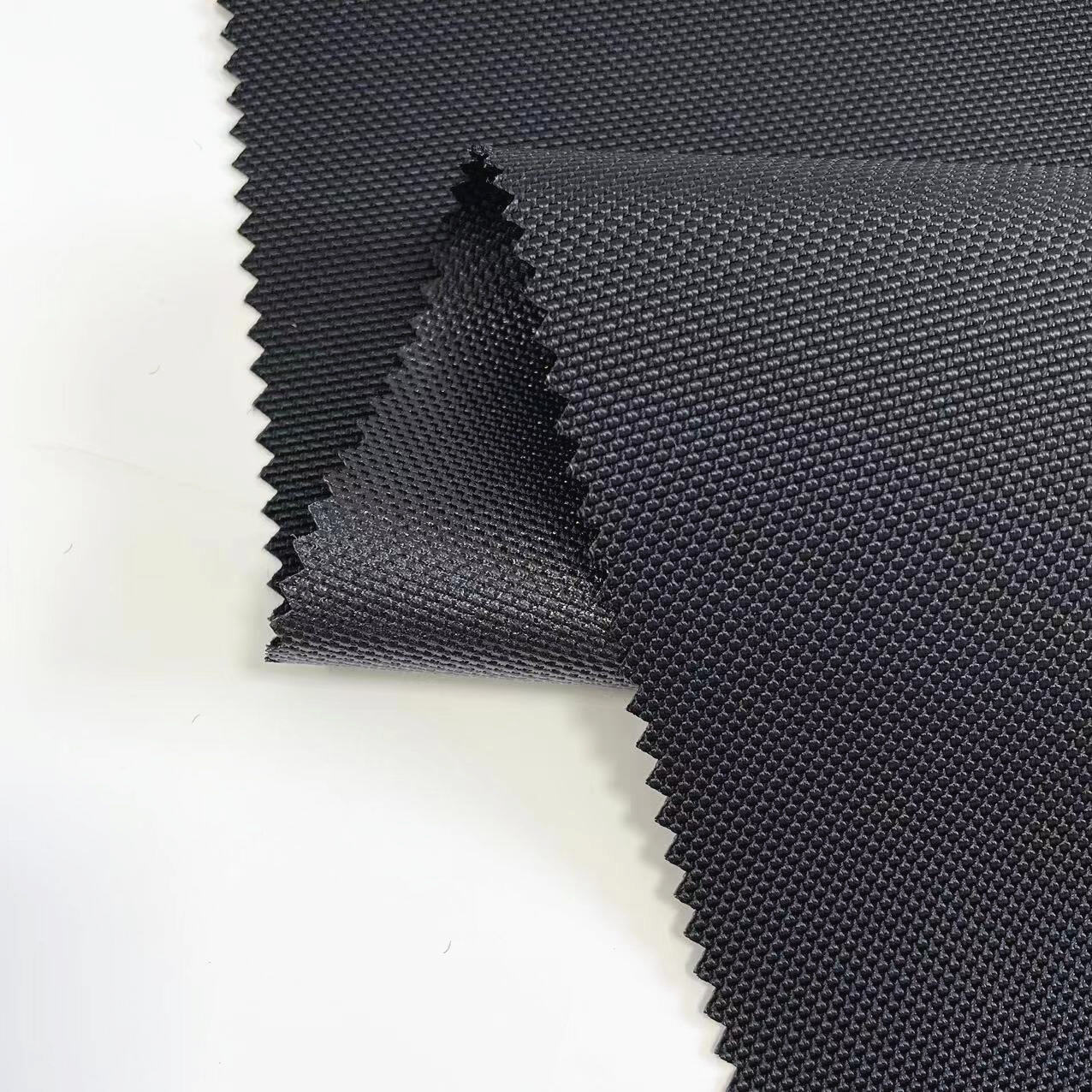

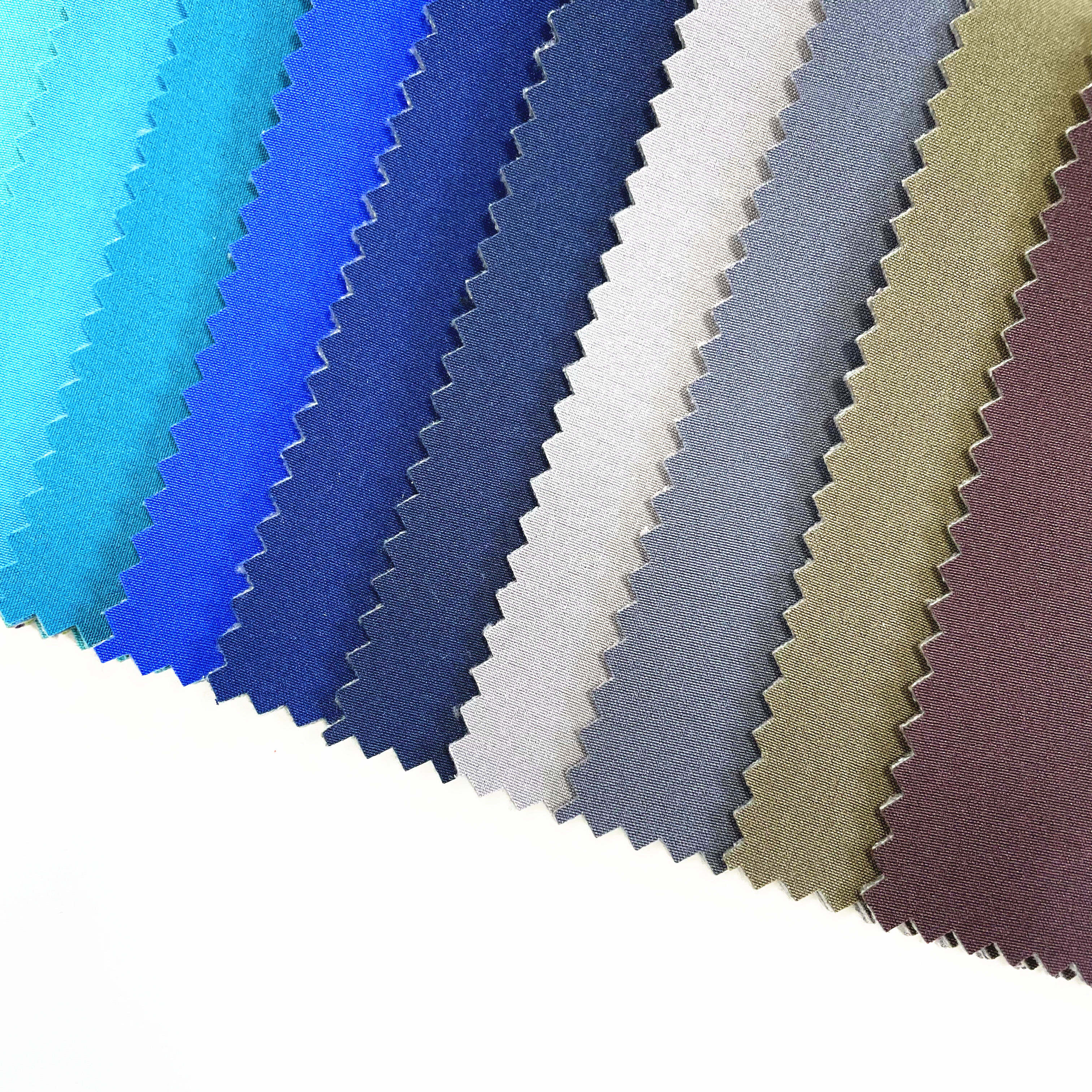

Suly Textile can nylon made from various types of custom-made fabrics to meet the demands of customers. Suly Textile is involved in the processing and sale of any kind of chemical fabric and blended fabric dyeing, coating, bonding and laminating. We specialize in functional fabrics such as strong water repellent fabric as well as high water column fabric. We also provide anti-static, anti-UV, moisture absorption, quick drying, anti-heat, flame retardant printed IFR and printed. Apart from that, we are able to accept low MOQ runs for printing. We provide a broad range of fabrics and can provide a one-stop solution.

Company main product: Softshell fabric, Hard shell fabric, RPET fabric Fabric for workwear, Bag fabric, Down jacket fabric, Aramid fabric Cordura Fabric that is nylon made from etc. In addition, our company offers custom-made service that can tailor-made to meet your requirements, such as Crinkled dyeing, Piece dyeing water repellent, printing Water column Teflon finishing, TPU coating, TPE coating, down proof, Anti-static, PU clear/milky coating and Flame retardant coating. High breathable coating, PA coating Cire, black-out coating, Embossed, Brushed, PVC lamination, PU transfer coating anti-UV, moisture absorption and quick drying, etc. Our product is widely utilized to make hiking jackets, skiing jackets, sports jackets down-proof outdoor clothing and children's sportwear, women's dress, etc.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our local certified 3rd party testing center who can give us fast, exact and certified testing reports. Our sales team is able to give quick and precise responses to the customer's needs. We also have a shipping staff that can offer solutions for shipping when the customer is having nylon made from with shipping.

Suly Textile, a professional fabric producer with a total of 20,000 sqm, includes four lines of coated PU lines. These lines coated with PU are all nylon made from and can provide a better quality coating. We also have two lines of PVC coating lines that primarily produce outdoor fabrics bags, tents and industrial using. Our technicians all have over 10 years of experience in the production of textiles and can provide a more controlled quality services and solutions. We are famous for our nylon fabric. We import dyes, greige, and finishing from Taiwan and finish them in our manufacturing facility.