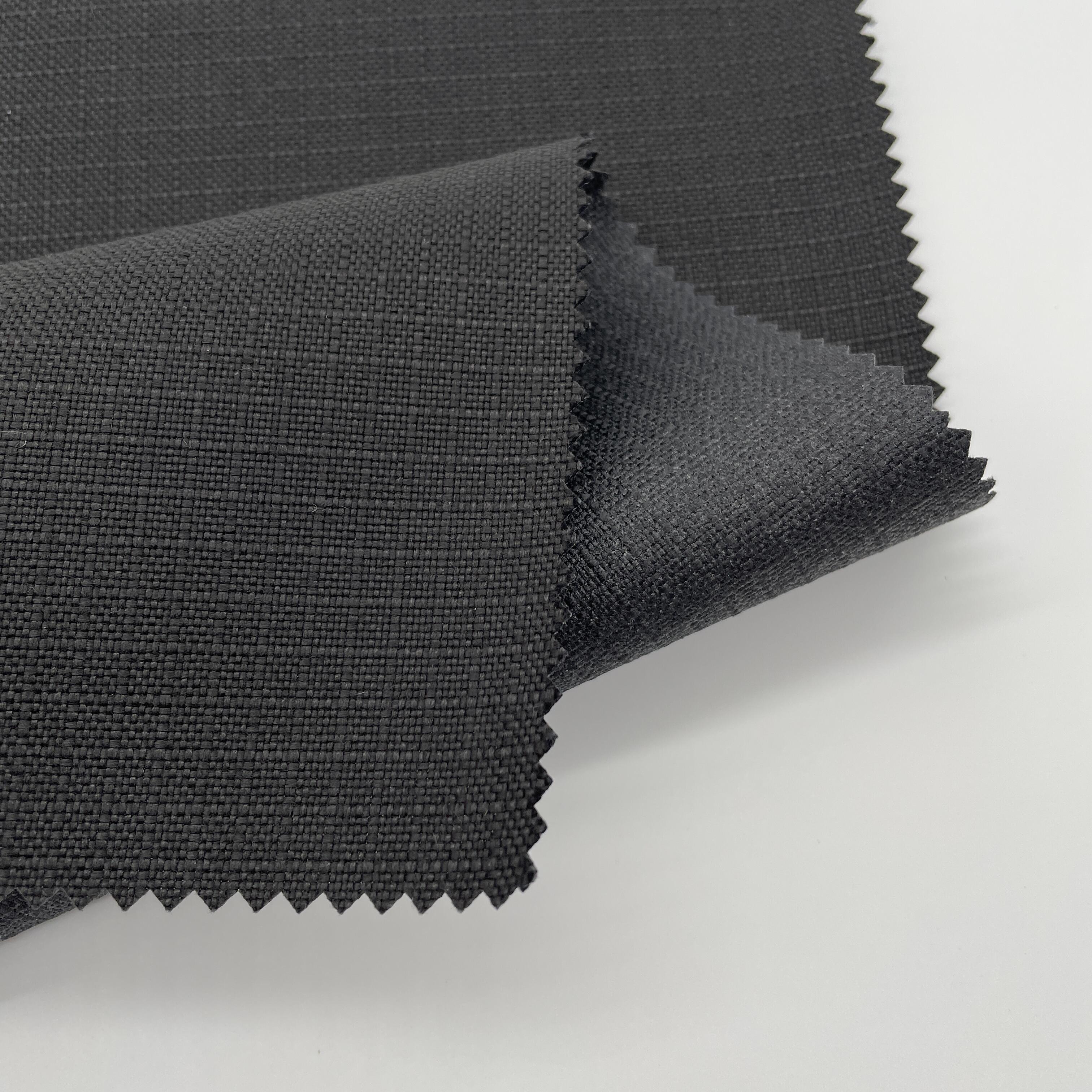

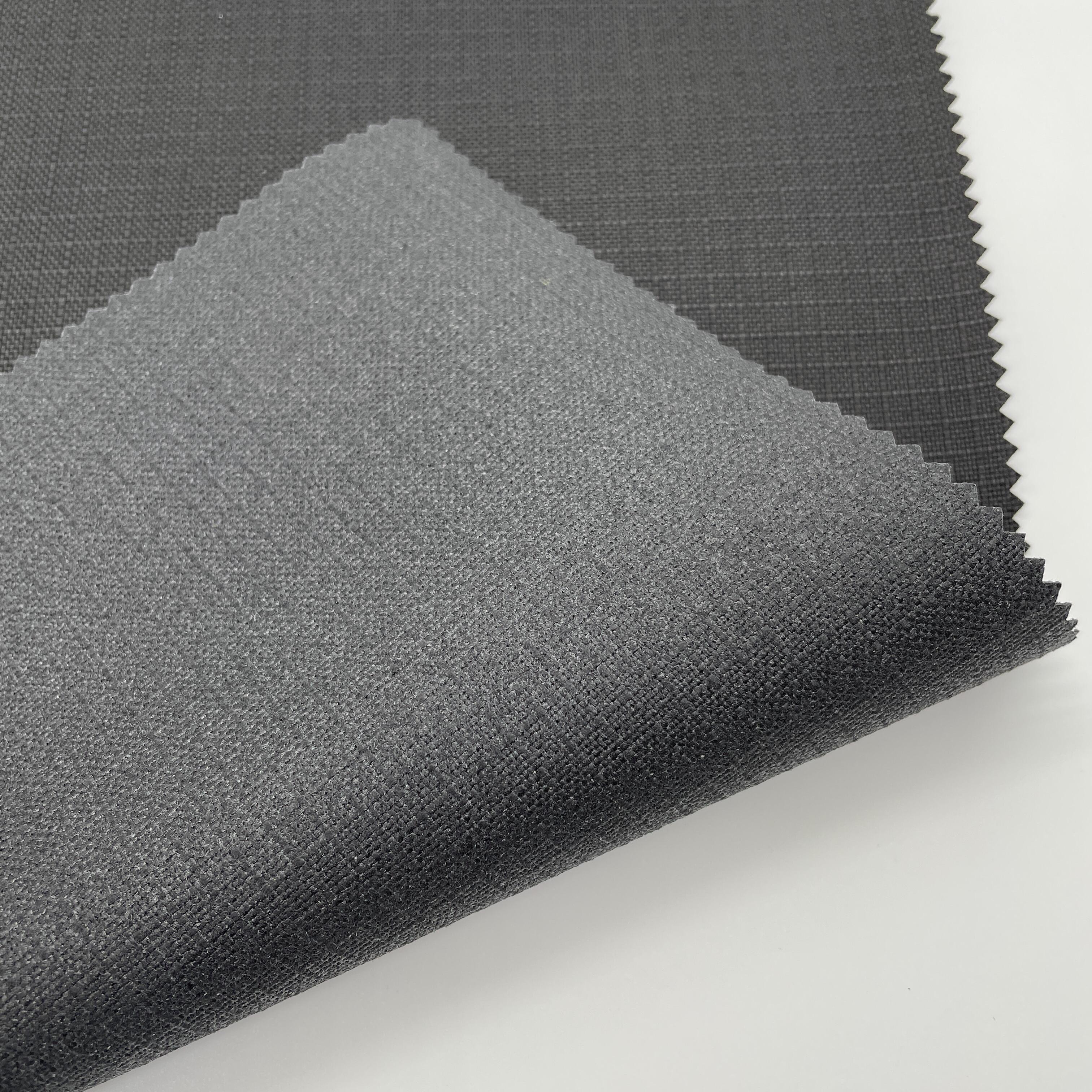

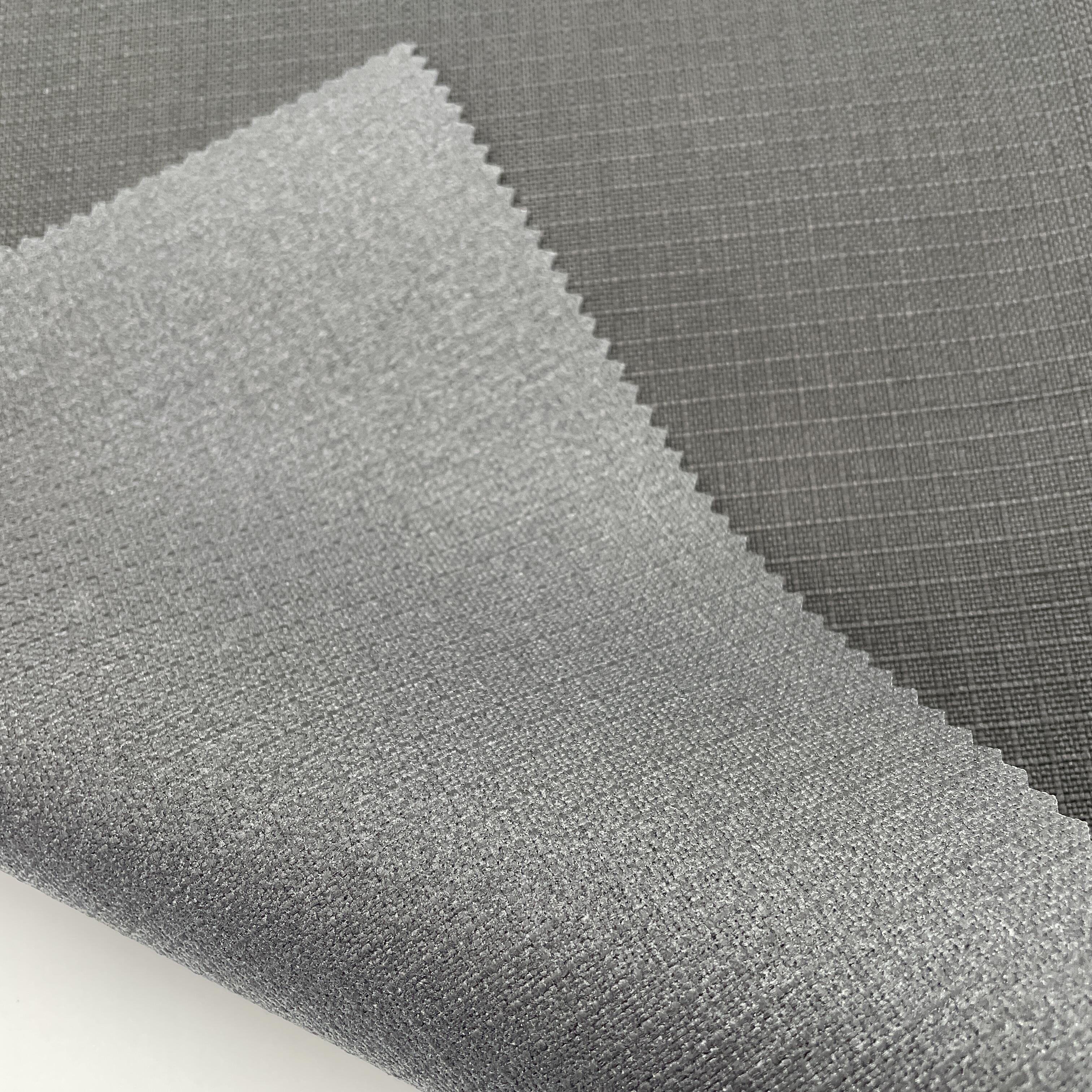

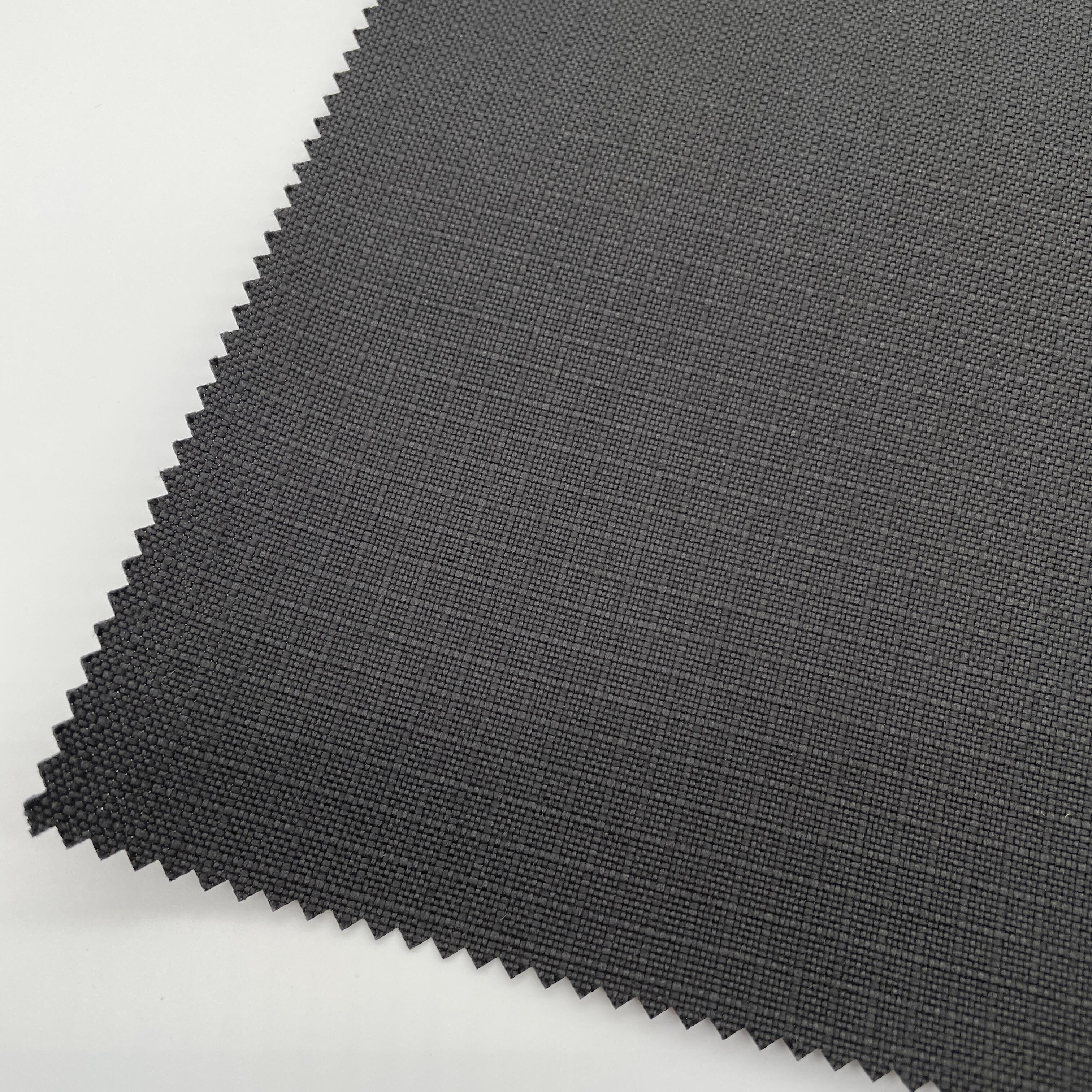

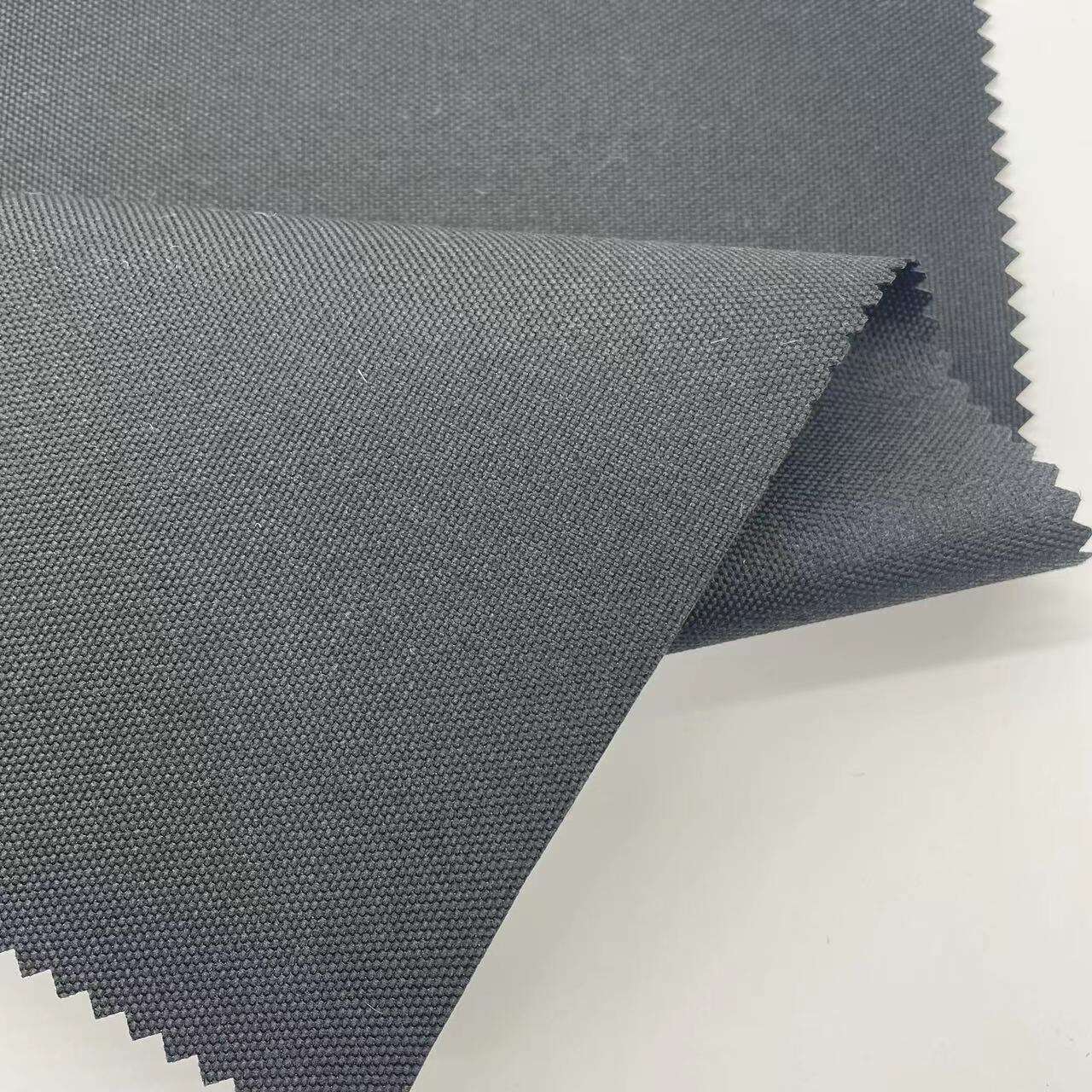

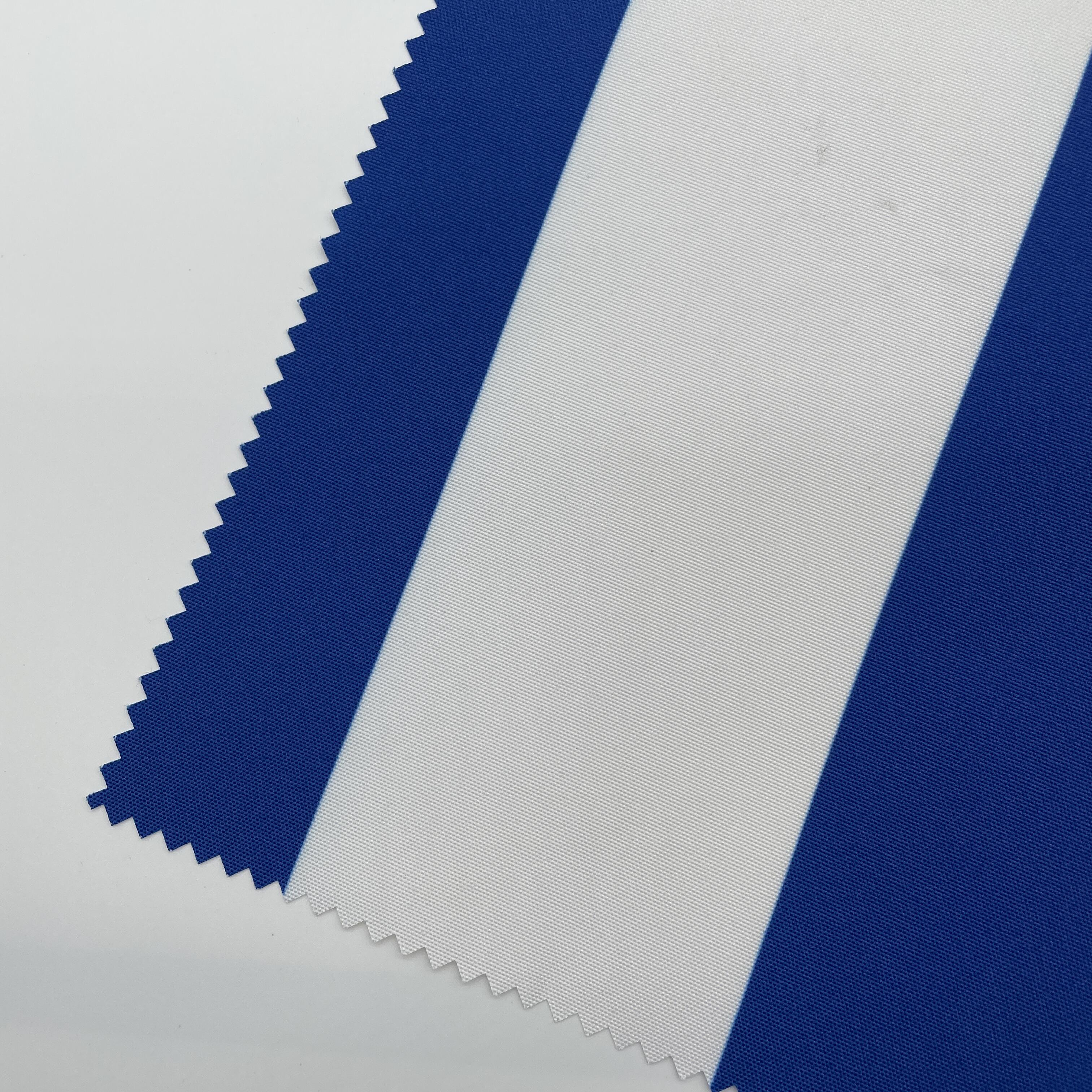

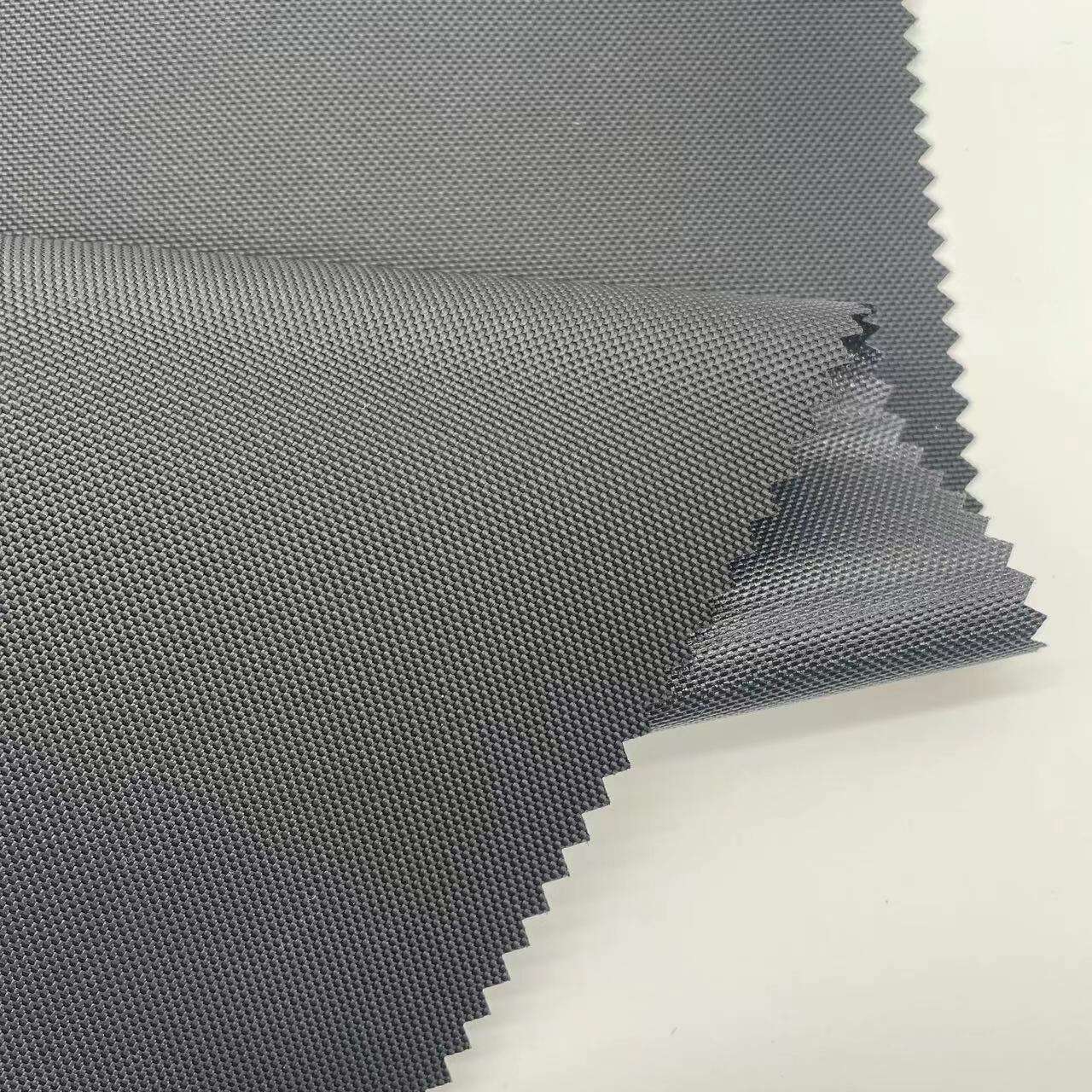

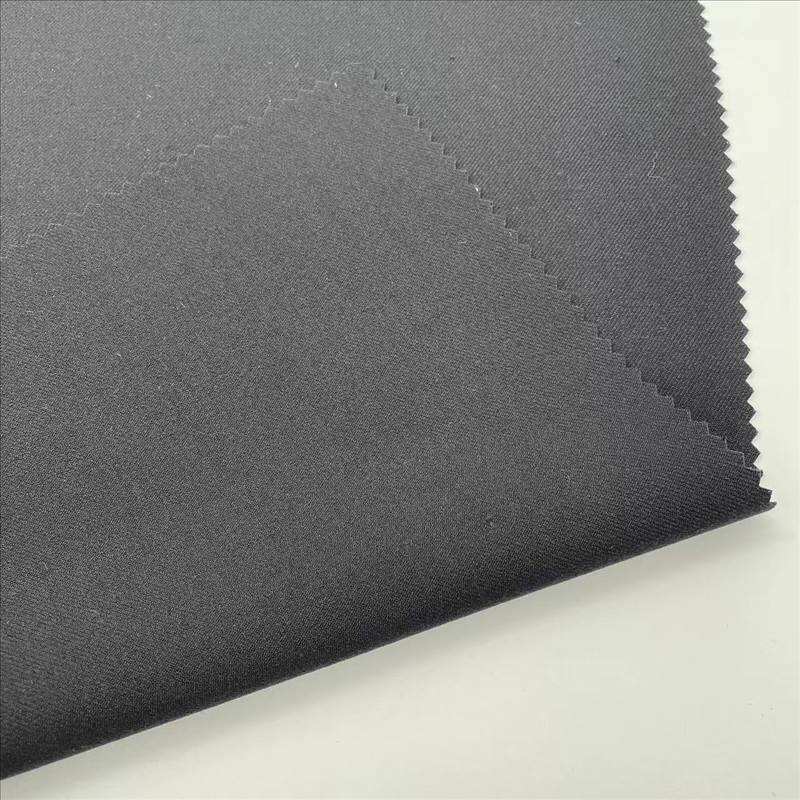

5MM rip-stop 1000D Textured Nylon fabric with PU coated

| Content: | Nylon |

| Coating: | PU(Polyurethane) |

| Country of origin: | China |

| Weaving: | Plaid |

| Minimum Order Quantity: | 1000Yards |

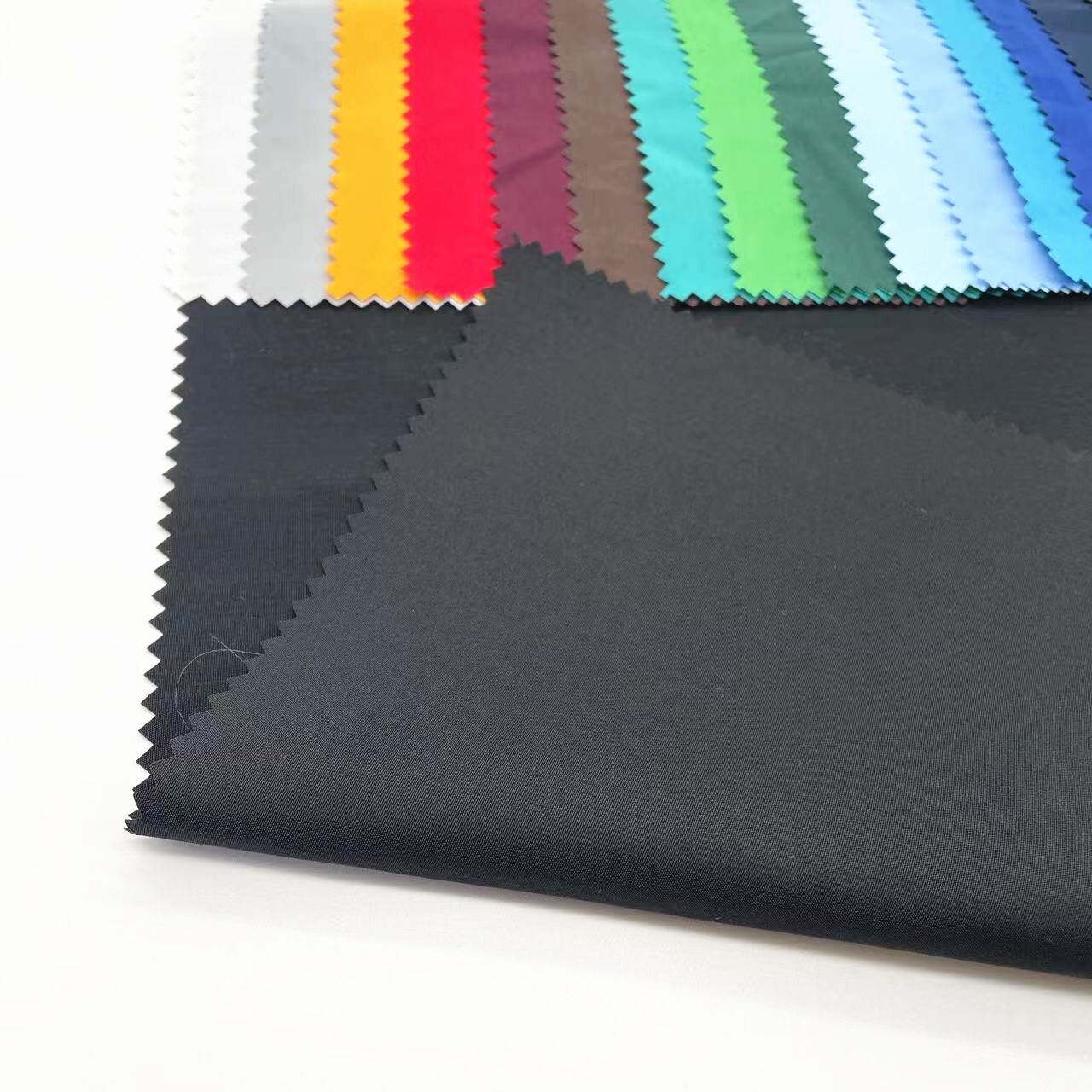

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 100yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

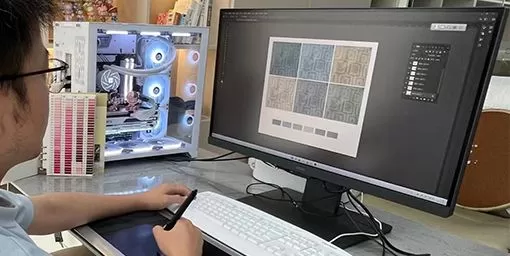

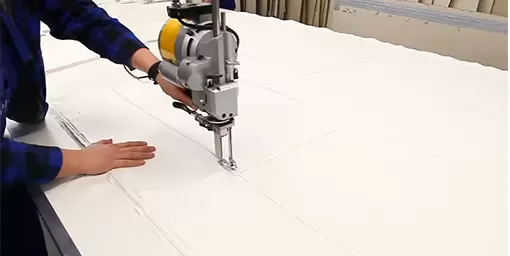

- Process flow

- Related products

- Inquiry

Parameter

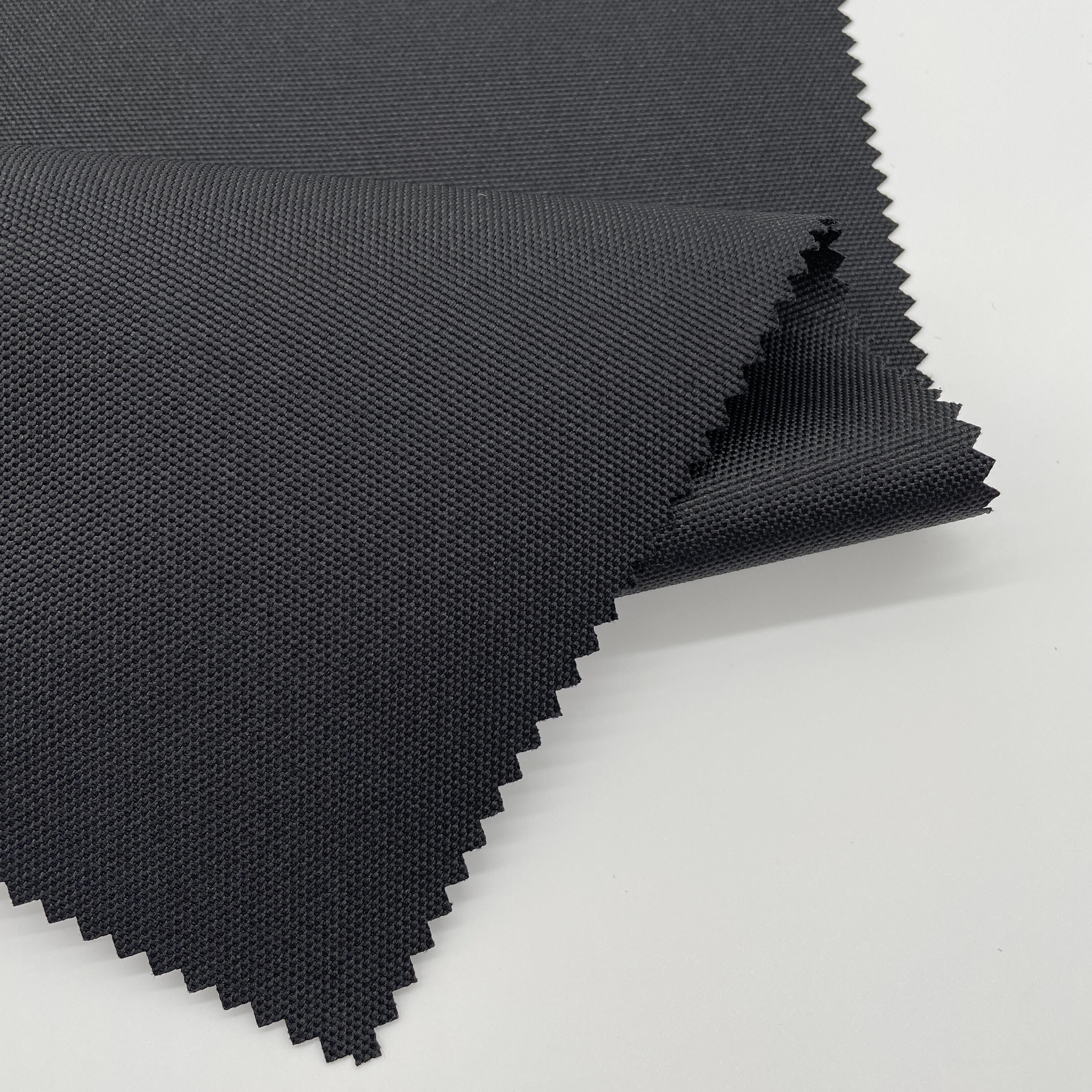

5MM rip-stop 1000D Textured Nylon fabric, a robust and versatile choice for various applications. This fabric is woven from 1000 Denier Nylon Air Textured Yarn, which provides the look and feel of cotton yarn while offering exceptional durability.

ATY known for its high-strength properties, surpasses polyester threefold and nylon 6 twofold in terms of strength. The fabric is designed with a distinctive check pattern, and the raised check pattern enhances tear resistance in specific areas. This feature ensures that the fabric can withstand rigorous use in military equipment, meeting the standards set by armies in European and American countries.

Our textured Nylon Plaid Ripstop Fabric finds wide applications in the production of tactical vests, military uniforms, shield shells, and heavy industry wear-resistant work clothes. Its durability, tear resistance, and strength make it a reliable choice for demanding environments.

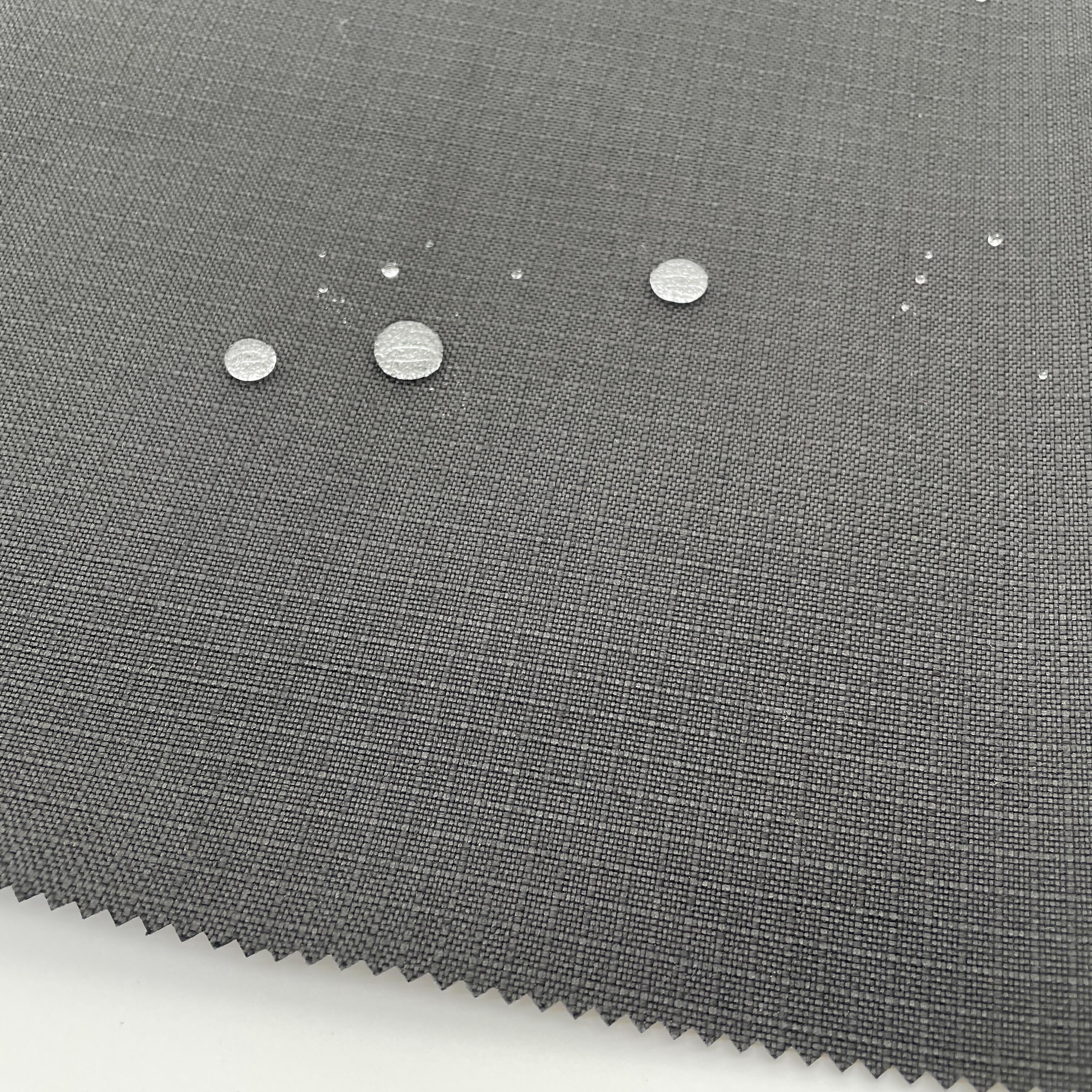

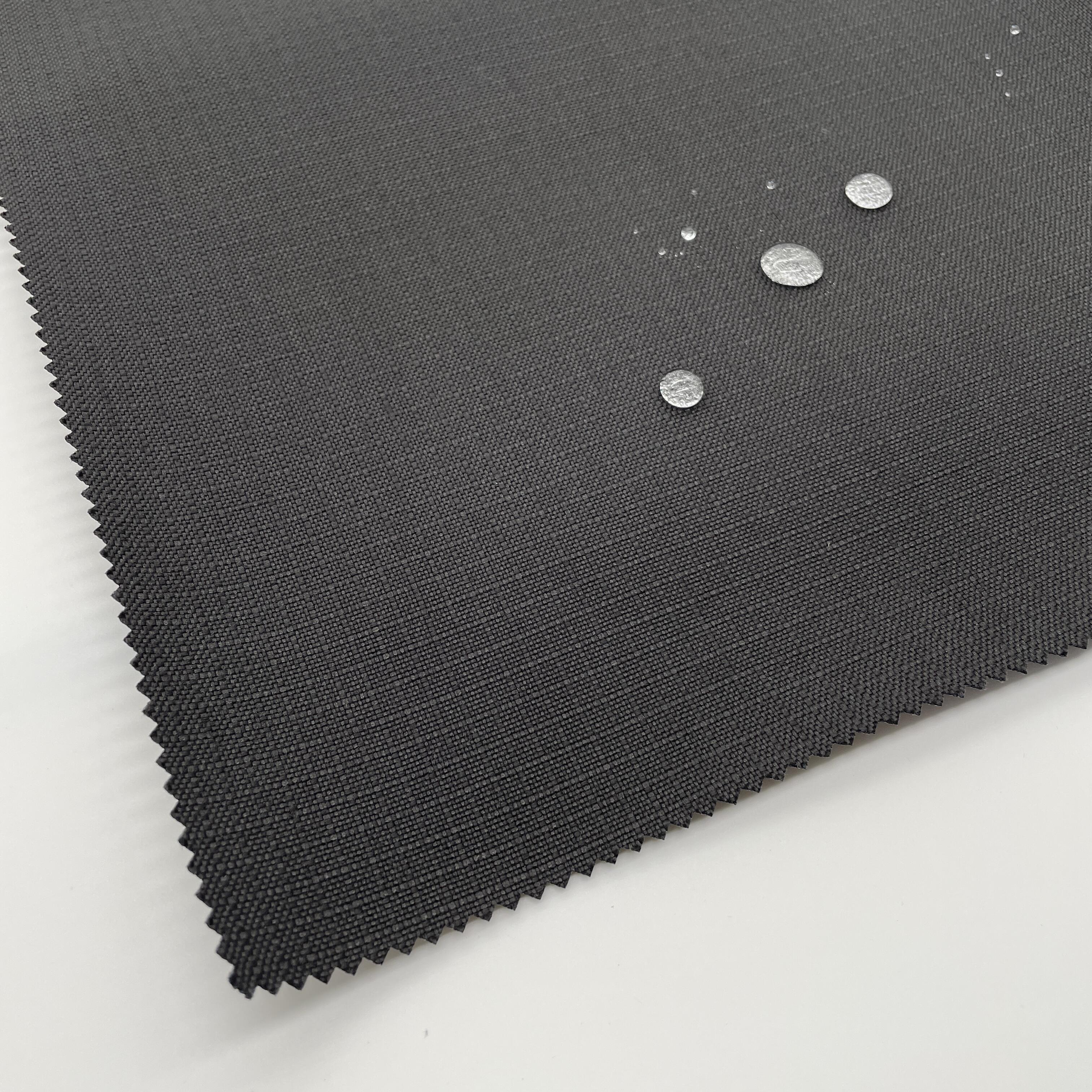

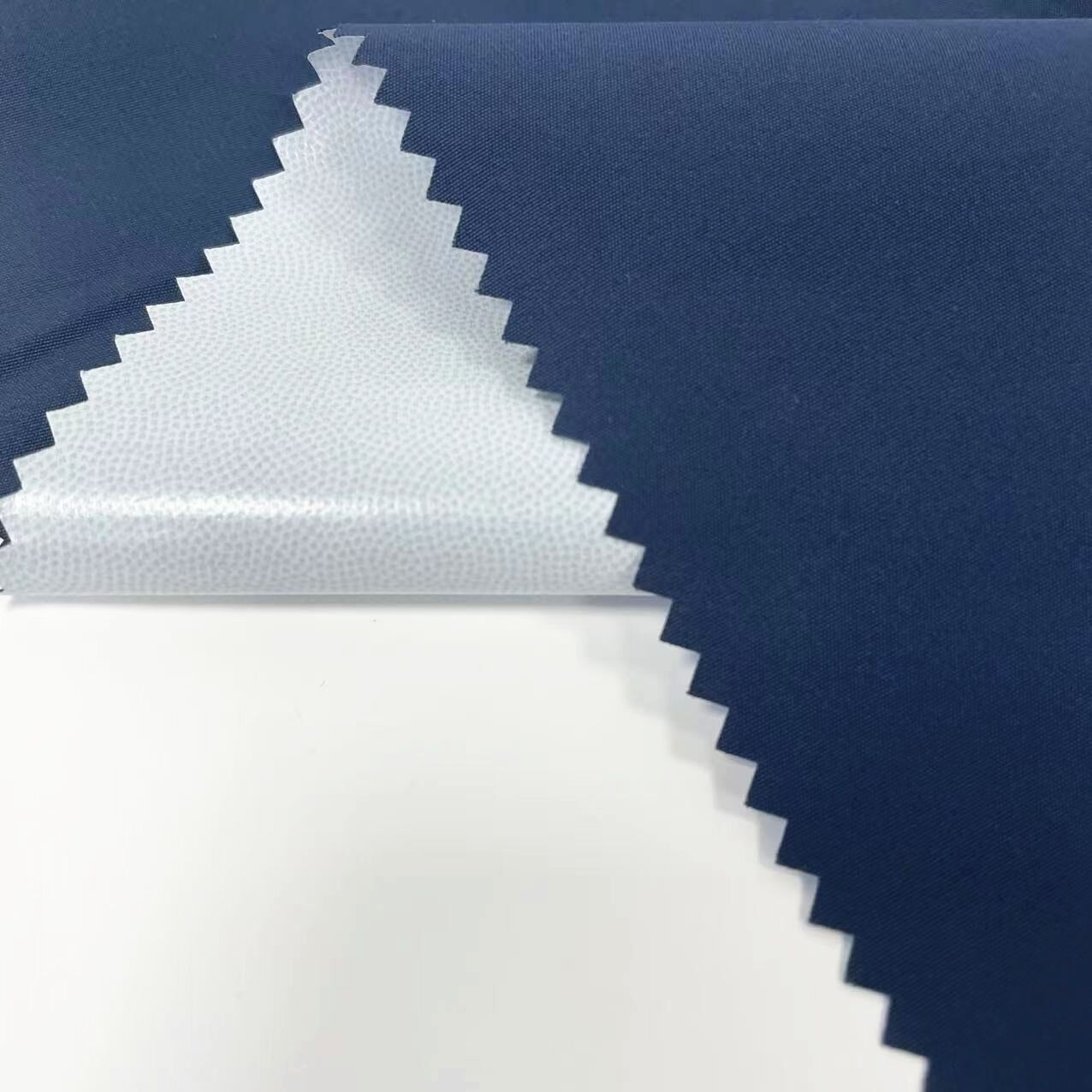

When your products face the world's harshest environments, they require a fabric engineered for absolute resilience. Our 5MM rip-stop 1000D Textured Nylon fabric with PU coated is specifically designed for this purpose, offering an unparalleled blend of extreme durability and reliable weather protection. The unique textured weave of the heavyweight 1000 Denier nylon base not only provides a distinctive, rugged aesthetic but also significantly enhances its resistance to abrasion, scuffs, and surface wear. The integrated rip-stop grid is a critical feature, effectively preventing small tears from expanding and compromising the integrity of your gear. This robust foundation is then sealed with a uniform polyurethane (PU) coating, creating a formidable barrier against moisture, ensuring your products remain dry and protected in demanding applications.

Our partnership with you begins long before production. We have designed a client-centric service process that prioritizes your unique needs. It starts with a technical dialogue to deeply understand the functional requirements of your end product. Following this, we manage the precise color-matching process in our lab and expedite fabric samples to you for hands-on evaluation and testing. Your dedicated project manager then oversees the entire production cycle, providing regular updates and ensuring strict adherence to your specifications. To empower innovators and established brands alike, we support small-batch customization with a accessible Minimum Order Quantity (MOQ) of 1000 meters, allowing you to bring specialized, high-quality products to market without excessive inventory risk.

We anchor our manufacturing process in verifiable quality and international technical standards. Every batch of our 5MM rip-stop 1000D Textured Nylon fabric with PU coated is subjected to a multi-point inspection protocol. Our quality control team performs rigorous in-house tests for coating delamination strength, hydrostatic resistance (exceeding 5000mm), and tear tensile strength. To provide you with irrefutable proof of performance, we can supply comprehensive test reports from independent, accredited laboratories. These documents serve as a certificate of quality, building a foundation of trust and giving you the confidence to market your products with authoritative claims about their durability and waterproof capabilities.

Why Make Us Your Strategic Supplier?

Choosing our 5MM rip-stop 1000D Textured Nylon fabric with PU coated is a decision for superior performance and supply chain reliability. You are not just purchasing a material; you are gaining a partner committed to upholding the highest standards of quality and consistency. Our dedication is proven through transparent quality control and readily available certification data. Combined with our flexible, low-MOQ production model and expert technical support, we provide the critical advantages needed to develop gear that stands up to extreme use and builds a powerful reputation for durability in the eyes of your customers.

Applications:

1000D nylon plaid ripstop fabric is commonly used in applications such as patient transfer, Ulcer Management, orthopedic, blood pressure cuff, tourniquet, life jacket, immersion suit, waterproof bags, outdoor backpack, map case,accessories, ponchos, hats, banners, sleeping bags, tents, backpack lining, covers, and umbrellas.

Specifications:

| Yarn: | 1000D*1000D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | plaid | Visual |

| Density(in): | 58T | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.70MM | ASTM D 1777 |

| Width: | 60'' | ASTM D 3774 |

| Weight: | 350GSM | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:180LBF, F: 175LBF | ASTM D1424 |

| Tensile strength 1'': | W:890LBF, F:880LBF | ASTM D5034-21 Grab test |

| Hydrostatic Pressure: | 800MM | AATCC TM127 |

Competitive Advantage:

High Quality

Factory direct sell price

Durable water repellent

High strength

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ