Get More for Your Money with Longer Life Nylon Monofilament Filter

One crucial cost-savings area involves extending the life of a company’s nylon monofilament filters. Making use of these long lasting filters helps to reduce maintenance costs, improve efficiency and can even help 'pad' your bottom line. In this blog, we explain how you can save a significant amount of money on filter replacements by making the most of your nylon monofilament filters.

Get the most for your money, while having long lasting filters

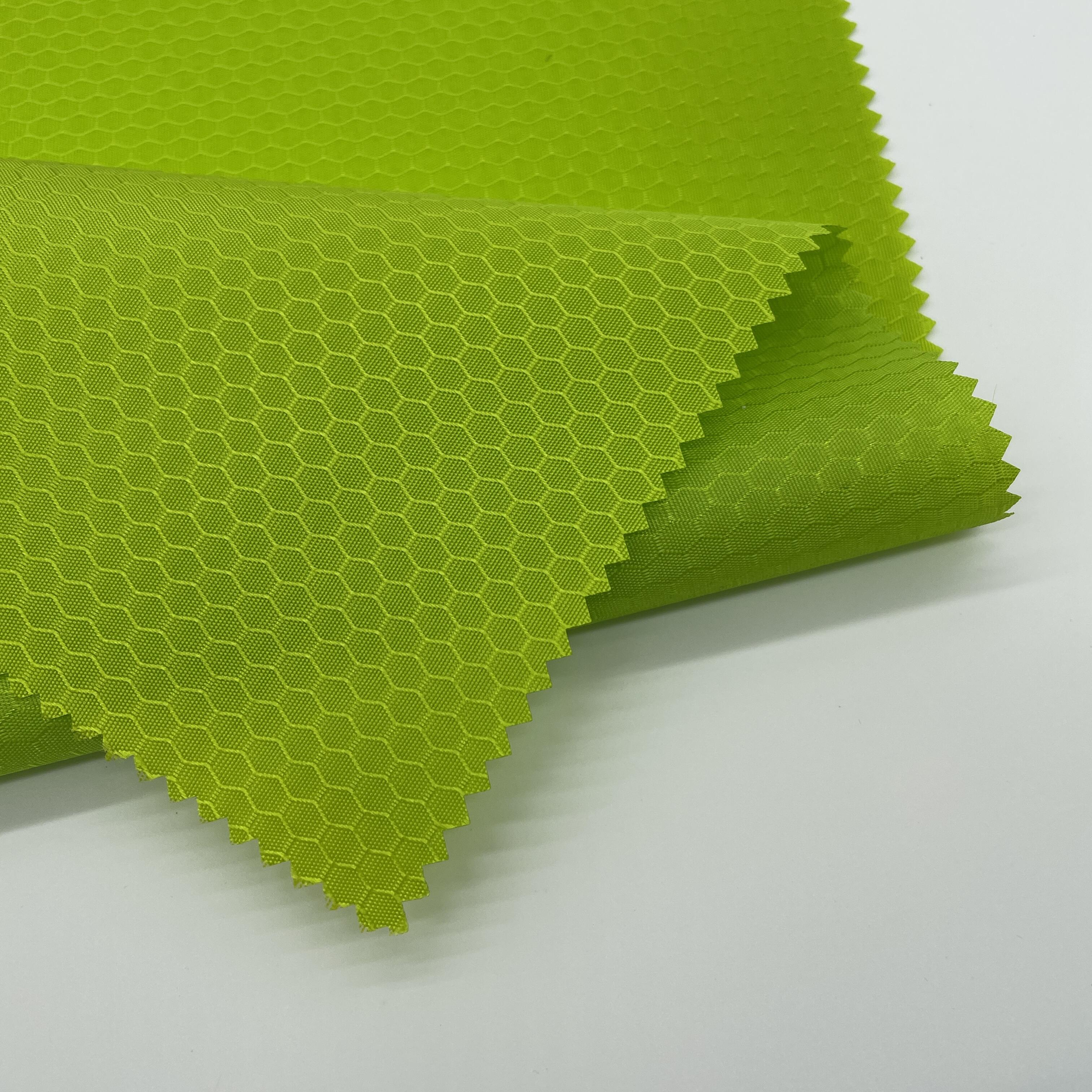

These filters are able to endure the demand of high use and can be cleaned and reused over and over again, which is an economical way to save money on your treatment. When you decide to purchase our high-grade nylon fiber through SULY Textile, you are not only improving efficiency across your manufacturing processes, but you are also decreasing how often they need changed.

Save on Maintenance with Longer Filter Life

Industrial companies can incur high maintenance costs, particularly as they need to frequently replace filters. Ongoing cost savings with nylon monofilament filters Selecting nylon and spandex fabric that last longer will be far less costly. The durable filters of SULY Textile can endure well rough conditions and easily be washed to reuse.

Increase Your Profit & Reduce your Cost by Using the Nylon Monofilament Filters

Truly every penny counts in this competitive market! With great value and long-lasting nylon spandex you’ll save big on replacement costs while noticing the difference in your bottom line. We at SULY Textile are dedicated to the optimization of our customers' process and cost efficiency. Our premium nylon monofilament filters are designed to be durable, easily rinsed and reusable.

Saving Costs With Durable Nylon Monofilament Filters

Changing out filters can be costly for any industrial business, especially when it needs to be done regularly. When you opt for our tough nylon monofilament filters, you will save a lot on replacements in the long run. Our filters are built for durability, so you only need to change them every 3-6 years, which is a more cost-effective solution compared to disposable filters.

Save thousands of dollars in replacement costs

The extending the life of your nylon monofilament filter and saving you more money, that's a win-win for any industrial manufacturer who is looking to save time and cost on maintenance. With a quality filter from SULY Textile, you can increase efficiency and reduce maintenance costs, ultimately increasing your bottom line.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ