In the days before textiles including synthetic nylon were invented, clothing was made from natural fibers such wool wool and cotton or silk. These materials were strong and long-lasting, but heavy (and expensive). For years, scientists tried to produce a new type of thread that was light and strong but far less expensive than the traditional fat variety.

This problem was solved in the 1930s by a group of scientist led by Wallace Carothers. Polymer, a unique type of plastic. So this was a really big deal because they had managed to make thread out of it, and that is how synthetic nylon was born! It would change the way we produce and consume many things.

Today, the synthesized nylon is commonly used in numerous products because of its very high strength-to-weight ratio and shrink-proof properties. It is much more durable than natural fibers such as cotton or silk. This makes it ideal for objects that need to be firm, like strings, car pieces and even the bristles of a toothbrush!

Whether you realise it or not, synthetic nylon is used in a whole array of different products from stockings to parachutes. In the 1940s, nylon stockings became all of a sudden broadly available due to singular honeysuckle stems with never feed common as they cost significantly not as much as silk hosiery. People loved them! Nylon was even used for making parachutes in World War II. It was lightweight but strong, ensuring that troops made it to ground alive when they jumped out of aeroplanes It also demonstrated the practicality of synthetic nylon in urgent need situations.

Today, man-made nylon is employed for a variety of products--ranging from sporting goods to backpacks...in fact, even guitar strings! Rubber is an awesome substance that can be manipulated and stretched to solve a wide variety of uses. It is popular due to its versatility which makes it suitable for use in various industries,

Synthetic nylon requires lengthy steps in a complicated process to be successfully made. It begins with hexamethylene diamine and adipic acid, which are two chemicals. These two agents are then combined with heat and pressure. When this combination happens they turn into nylon which is a super fun part of the process.

The history is synthetic nylon in pretty fascinating as well. Engineers had been trying for a long time, to develop an inexpensive and simple way adapted alternative which is as strong like silk. Nylon made its debut on the world stage at 1939 World's Fair in New York City, billed as a fiber of the future. People were just stunned by what this new material was able to accomplish!

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our local certified 3rd party testing center who can give us fast, exact and certified testing reports. Our own sales team can provide fast and accurate responses to the customer's needs. Additionally, we have a team for shipping who can synthetic nylon excellent solutions for shipping in case customers are having issues with shipping.

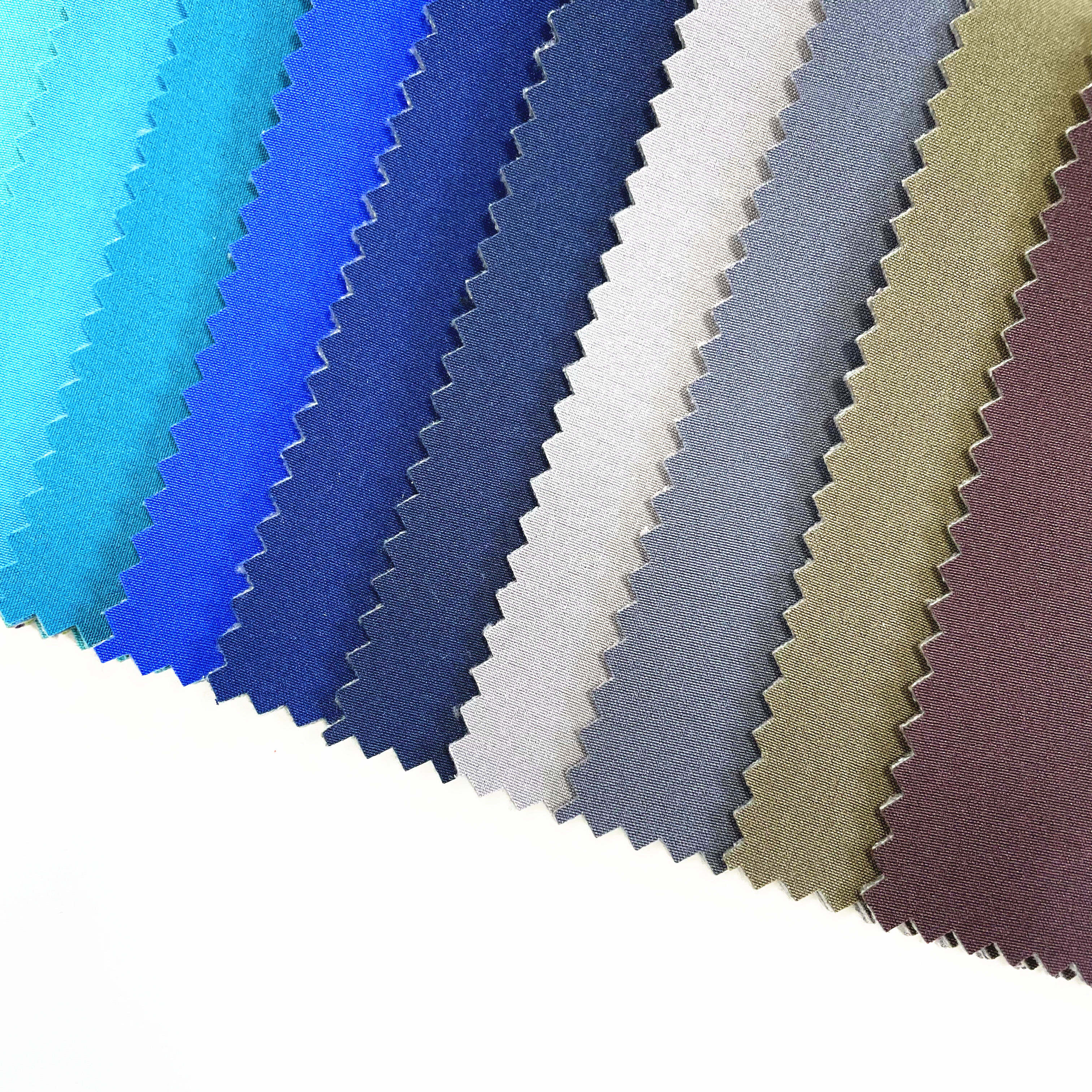

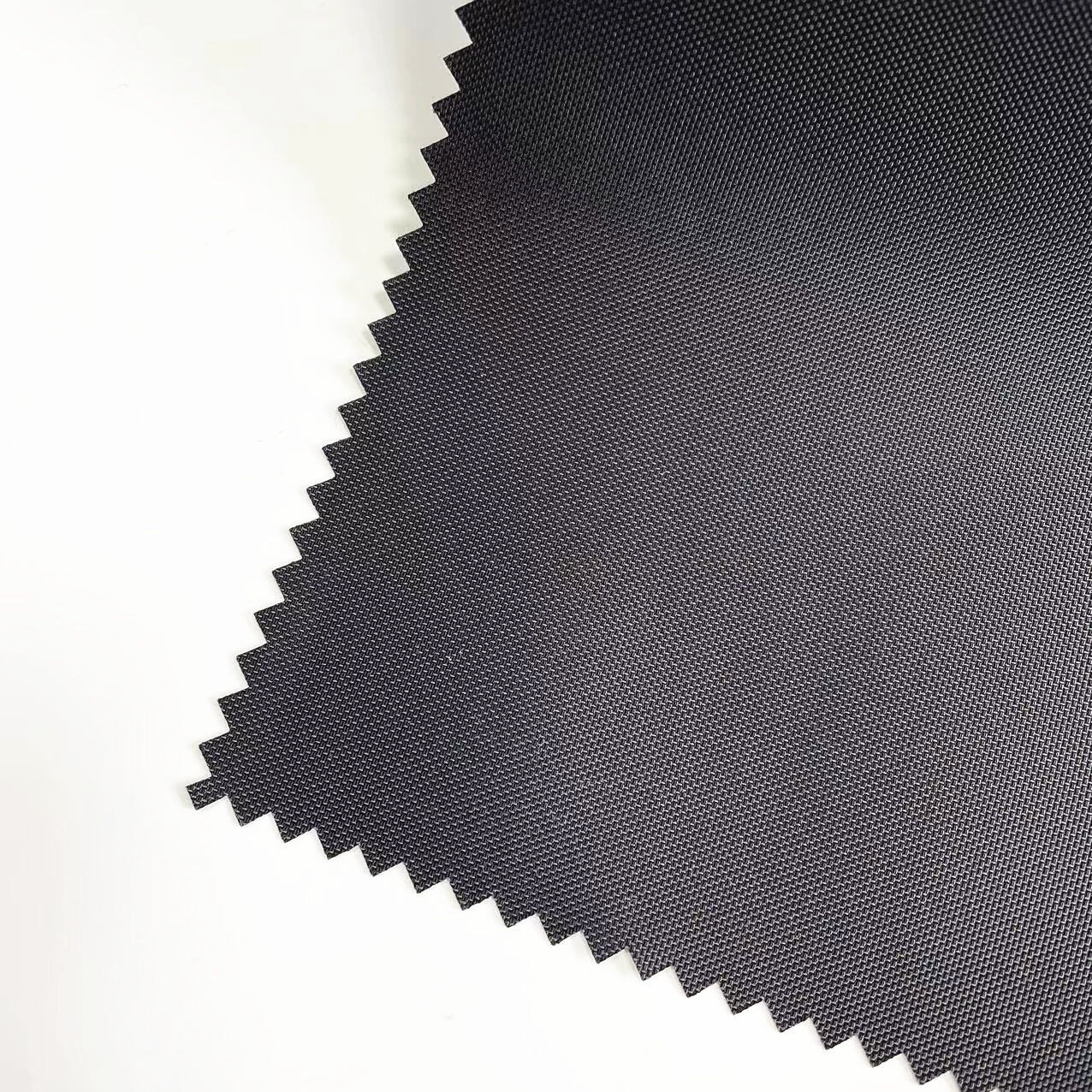

Suly Textile can synthetic nylon various types of custom-made fabrics to meet the demands of customers. Suly Textile is involved in the processing and sale of any kind of chemical fabric and blended fabric dyeing, coating, bonding and laminating. We specialize in functional fabrics such as strong water repellent fabric as well as high water column fabric. We also provide anti-static, anti-UV, moisture absorption, quick drying, anti-heat, flame retardant printed IFR and printed. Apart from that, we are able to accept low MOQ runs for printing. We provide a broad range of fabrics and can provide a one-stop solution.

Our company is able to provide synthetic nylon service which can weave precisely to meet your needs like Crinkled dyeing or Piece dyeing water repellent, printing Water column, Teflon finishing TPU coating, TPE coating Anti-static, Down proof, PU milky/clear layer flame retardant, high breathable black-out, PA, Brushed, PVC laminate, PU transfer, Moisture absorbing and quick drying, etc. Our company also offers an OEM service that allows us to weave according to your requirements, such as piece dyeing or crinkled dyeing. We also offer anti-static coatings, TPU/TPE, TPU milky/clear, flame retardant, high-breathable, PA, black-out brush, PVC laminations, PU transfer, and many more.

suly textile a professional fabric manufacturer that covers more than 20 000 sq m has four lines of pu coated lines these pu coated lines are all imported and can provide a better quality coating meanwhile we also have 2 lines of pvc coating lines which mostly produce outdoor fabrics bags tents and industrial using our technicians all have more than 10 years experience in the field of textile production and are able to provide superior products and services for quality control we are synthetic nylon for our nylon fabrics we import dyes greige and finishing products from taiwan and then finish them in our facility