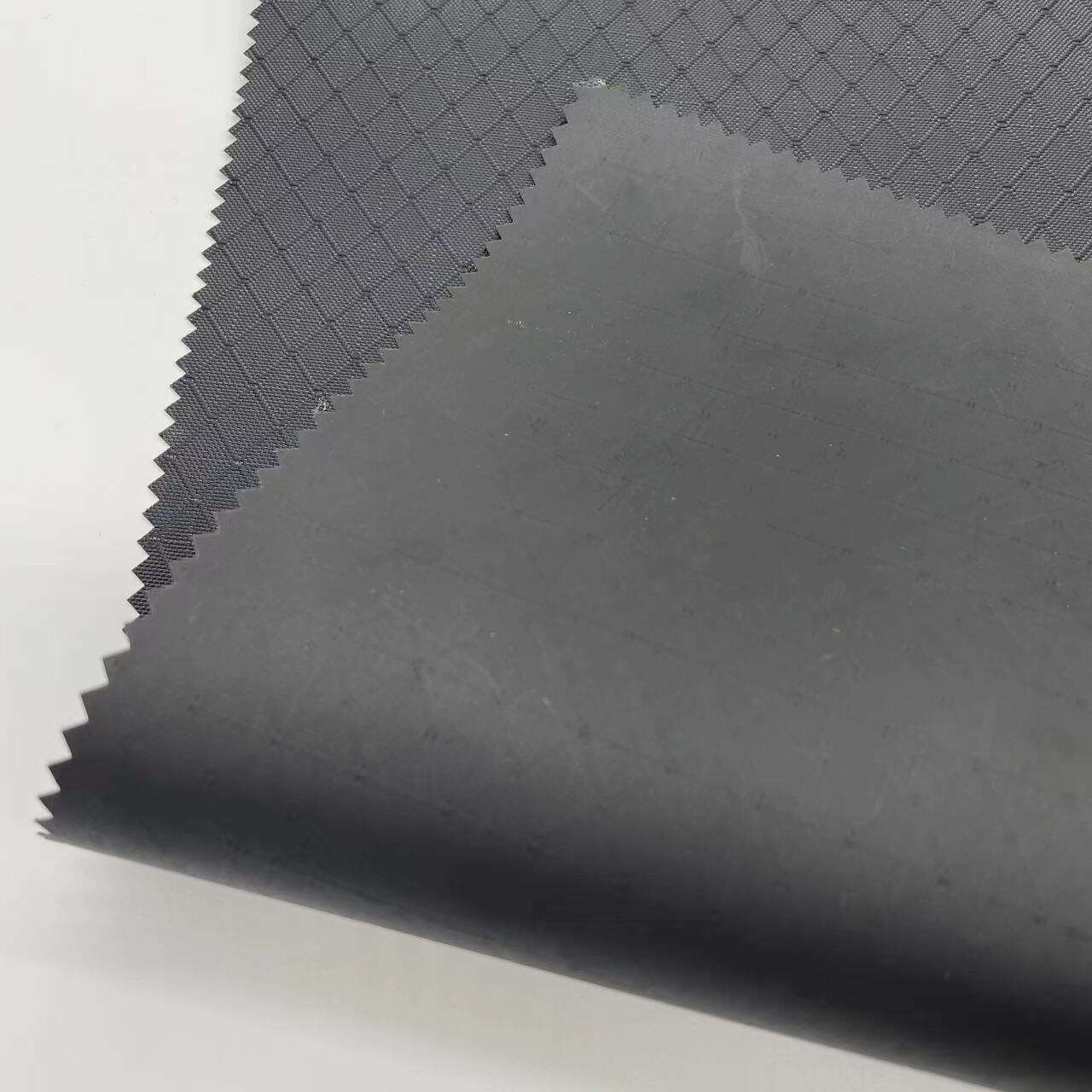

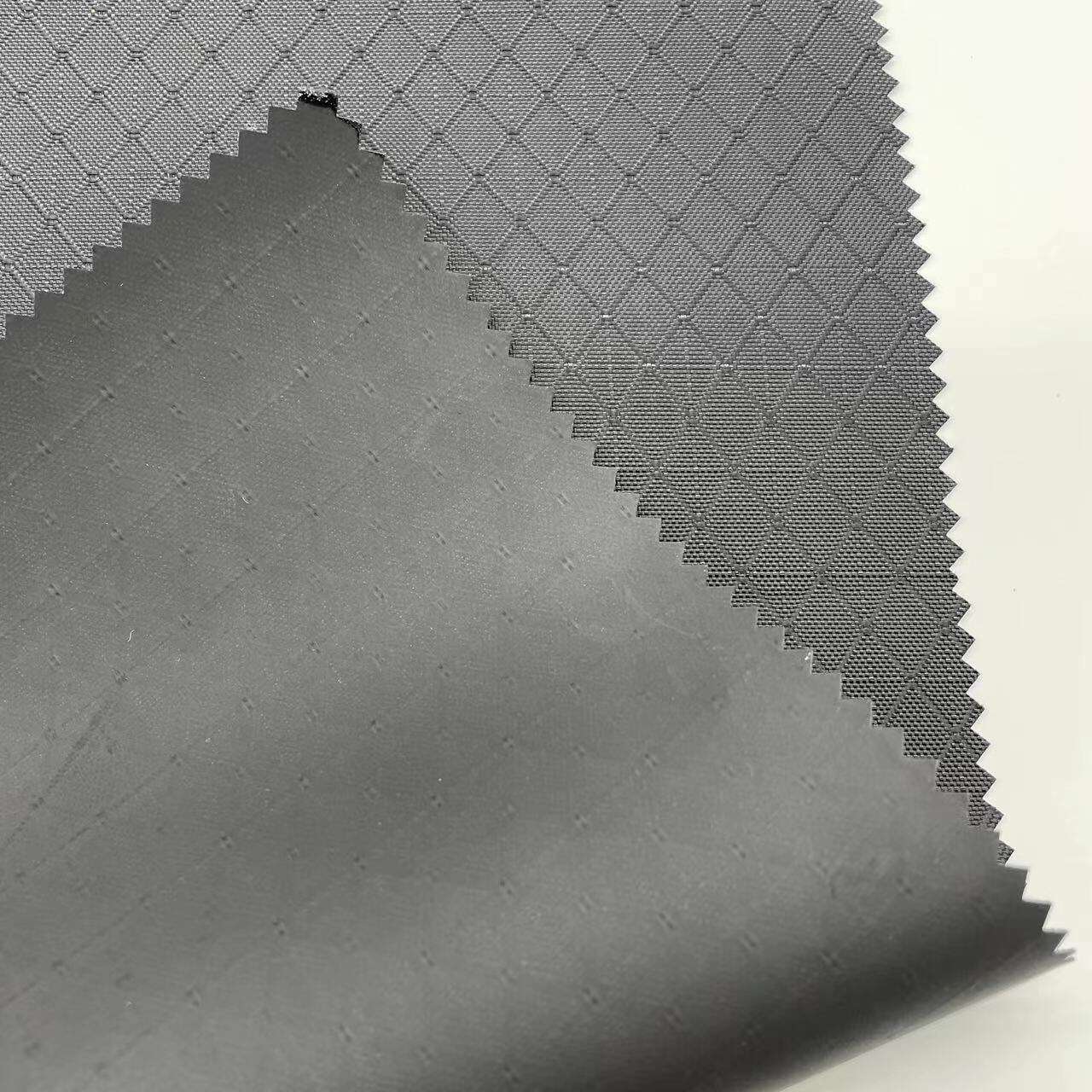

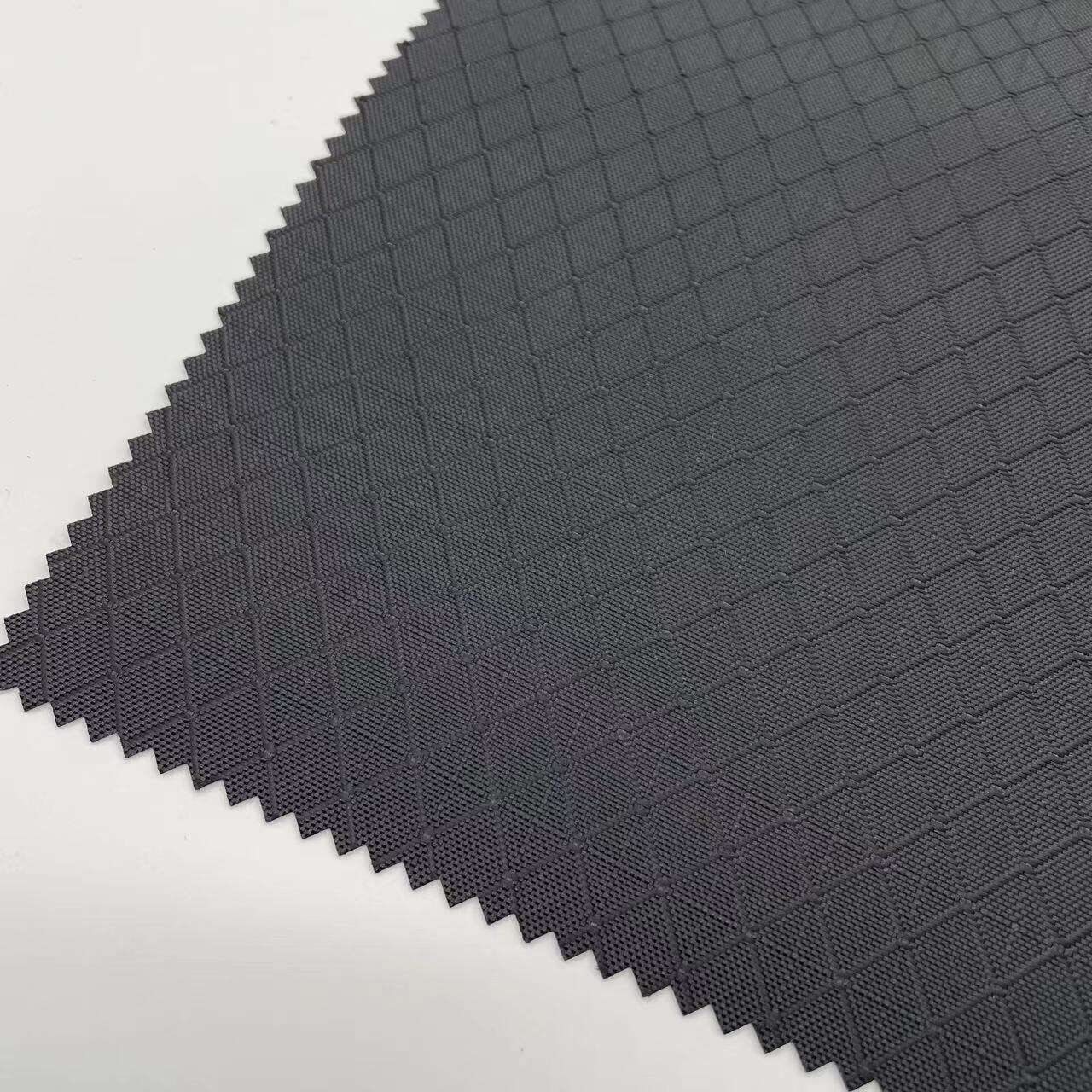

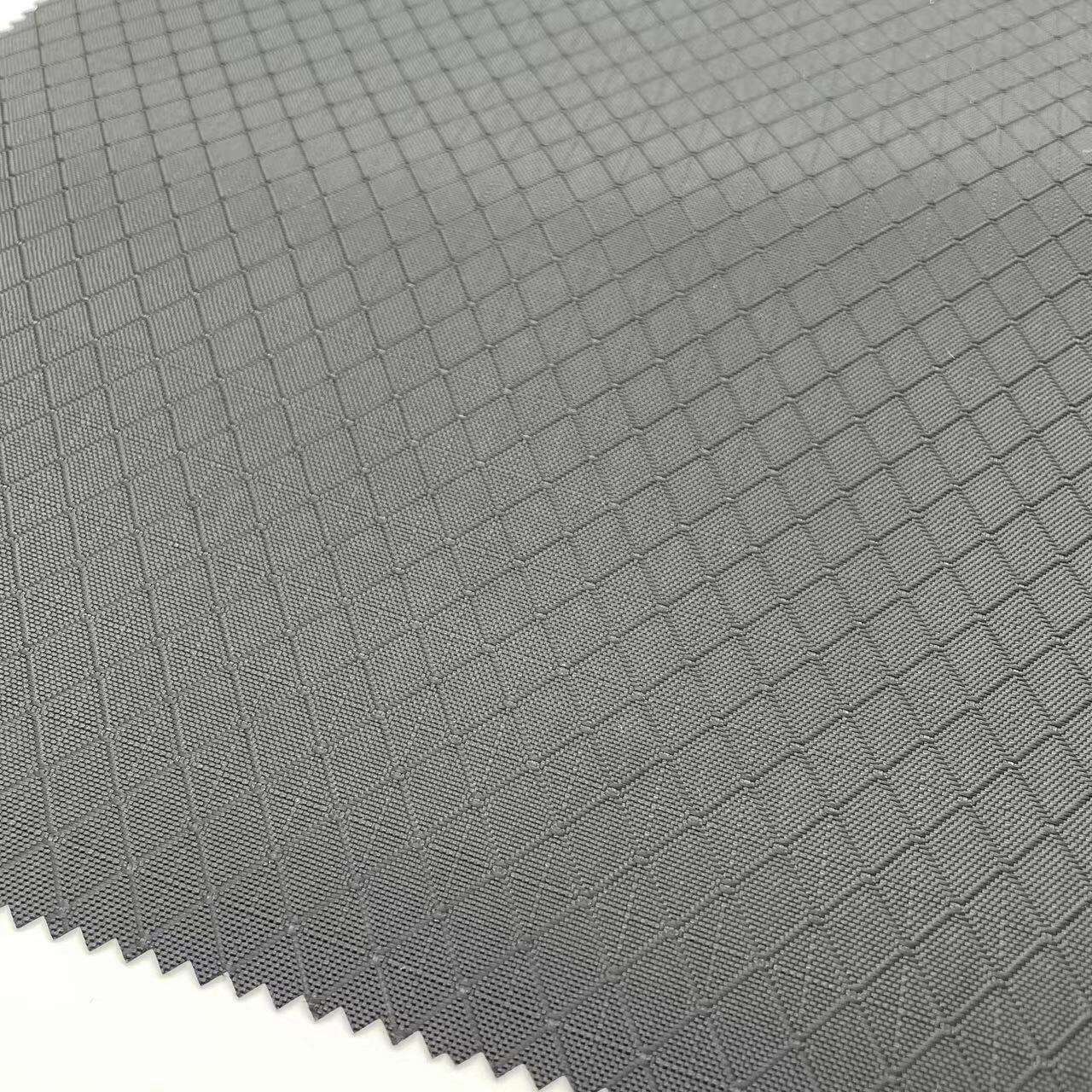

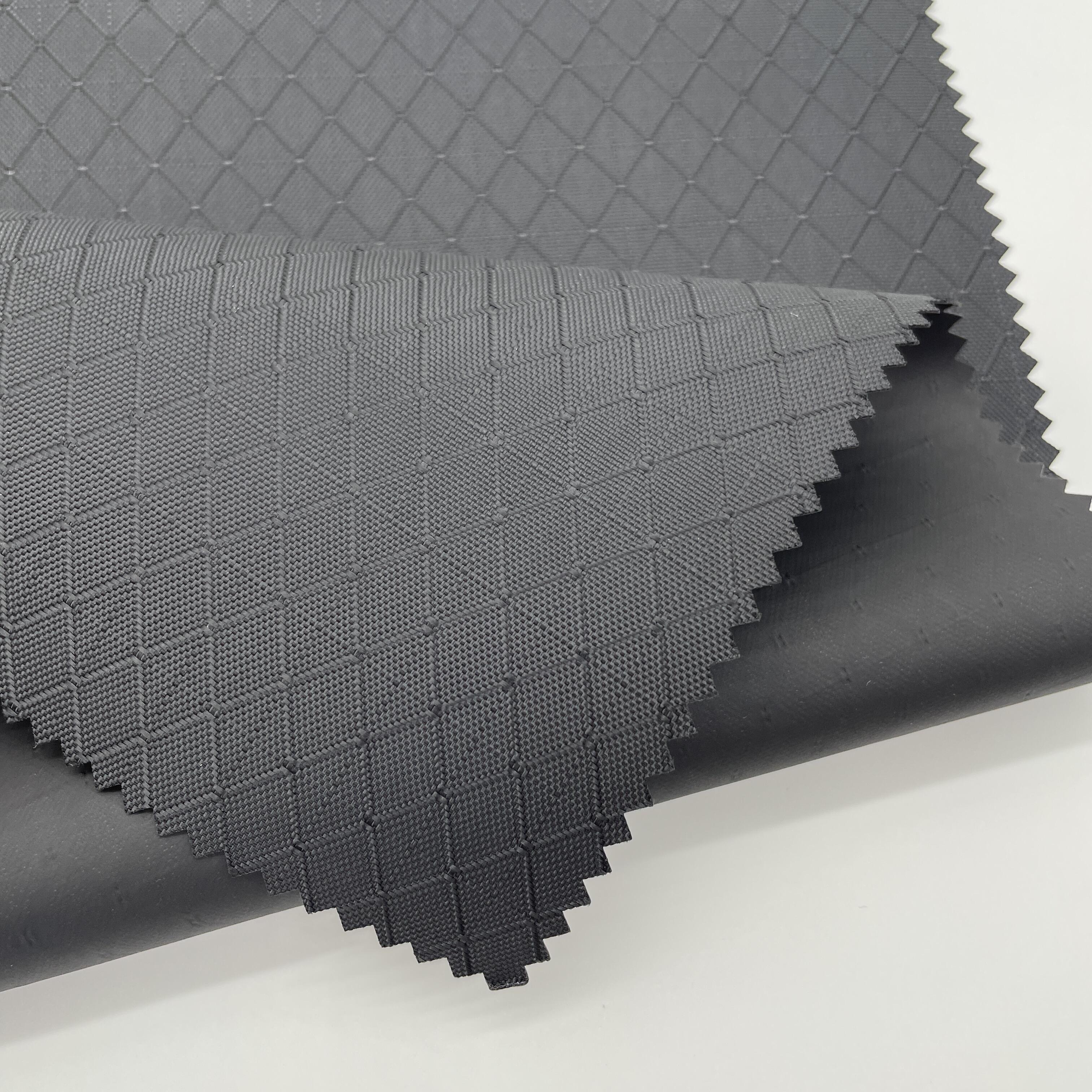

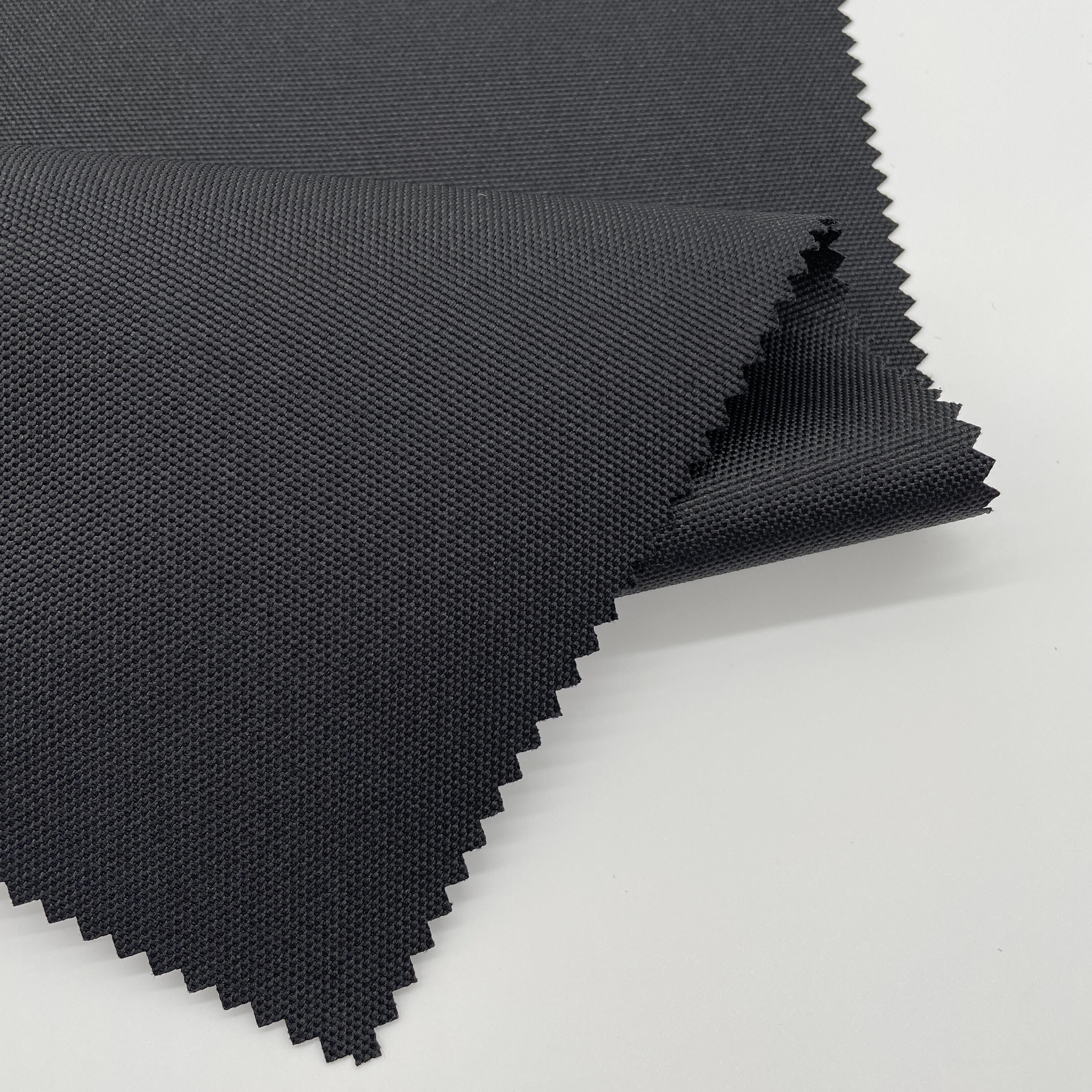

Weldable TPU coated 420D diamond rip-stop fabric

| Content: | Nylon |

| Coating: | TPU(thermoplastic polyurethane) |

| Country of origin: | China |

| Weaving: | Diamond |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 100yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

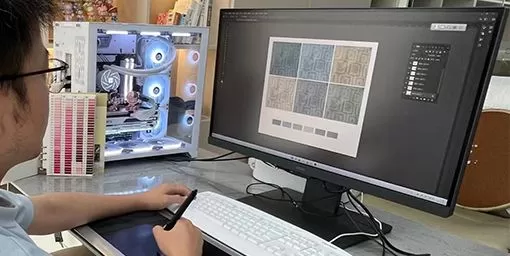

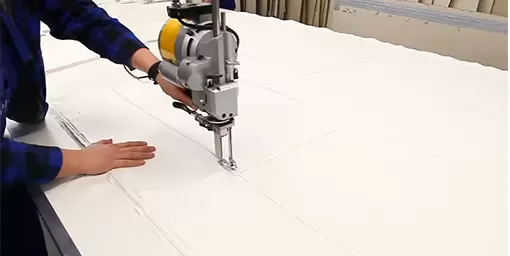

- Process flow

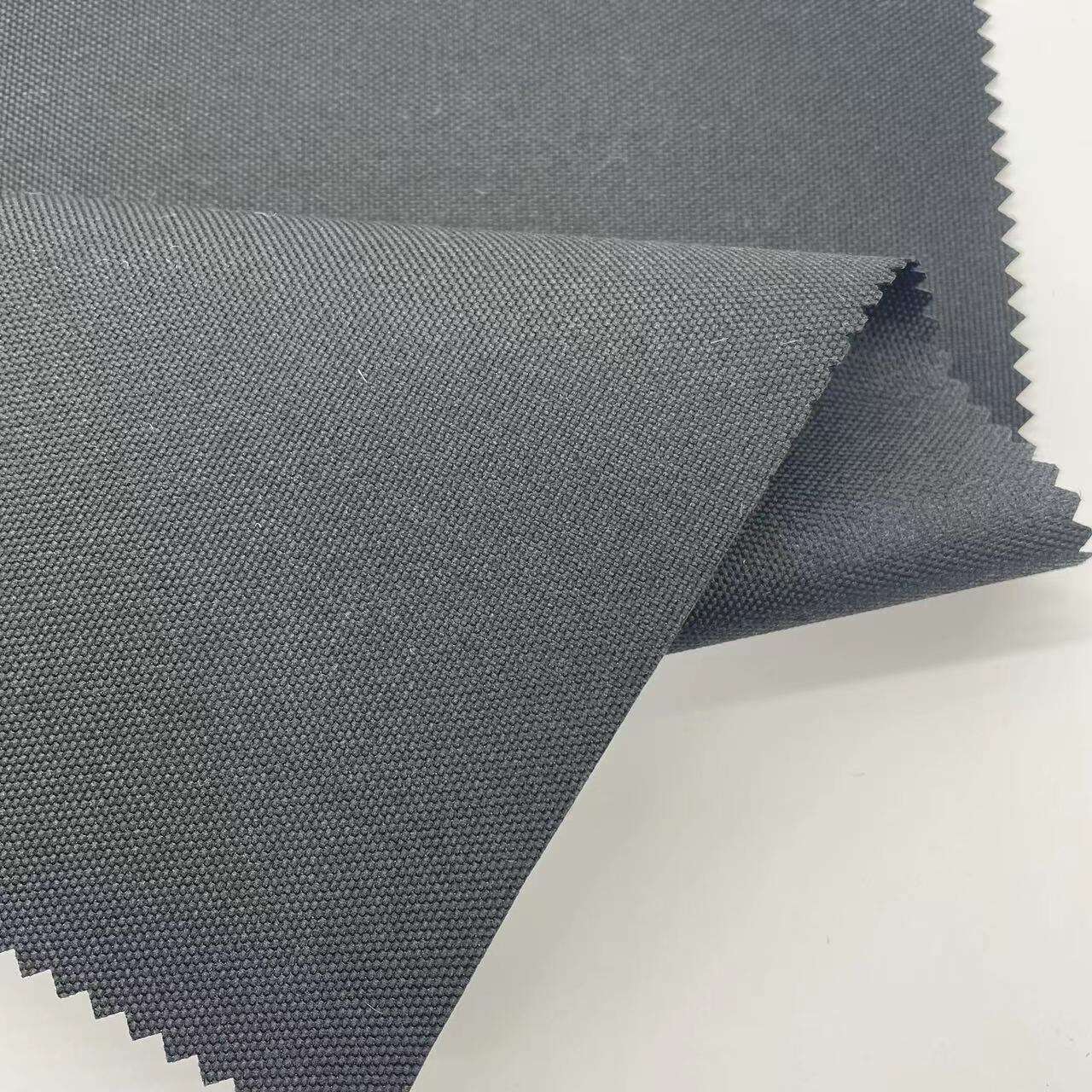

- Related products

- Inquiry

Parameter

This TPU Black Nylon can also be used for many other homemade adventure products. From cycle bags/panniers to waterproof stuffbags/dry bags. Abrasion-resistant, tear-resistant, resistant to low temperature and ageing. Can be heat-sealed to be completely airtight as well as waterproof.

· High Melting Point Nylon

· 420 Denier Oxford weave

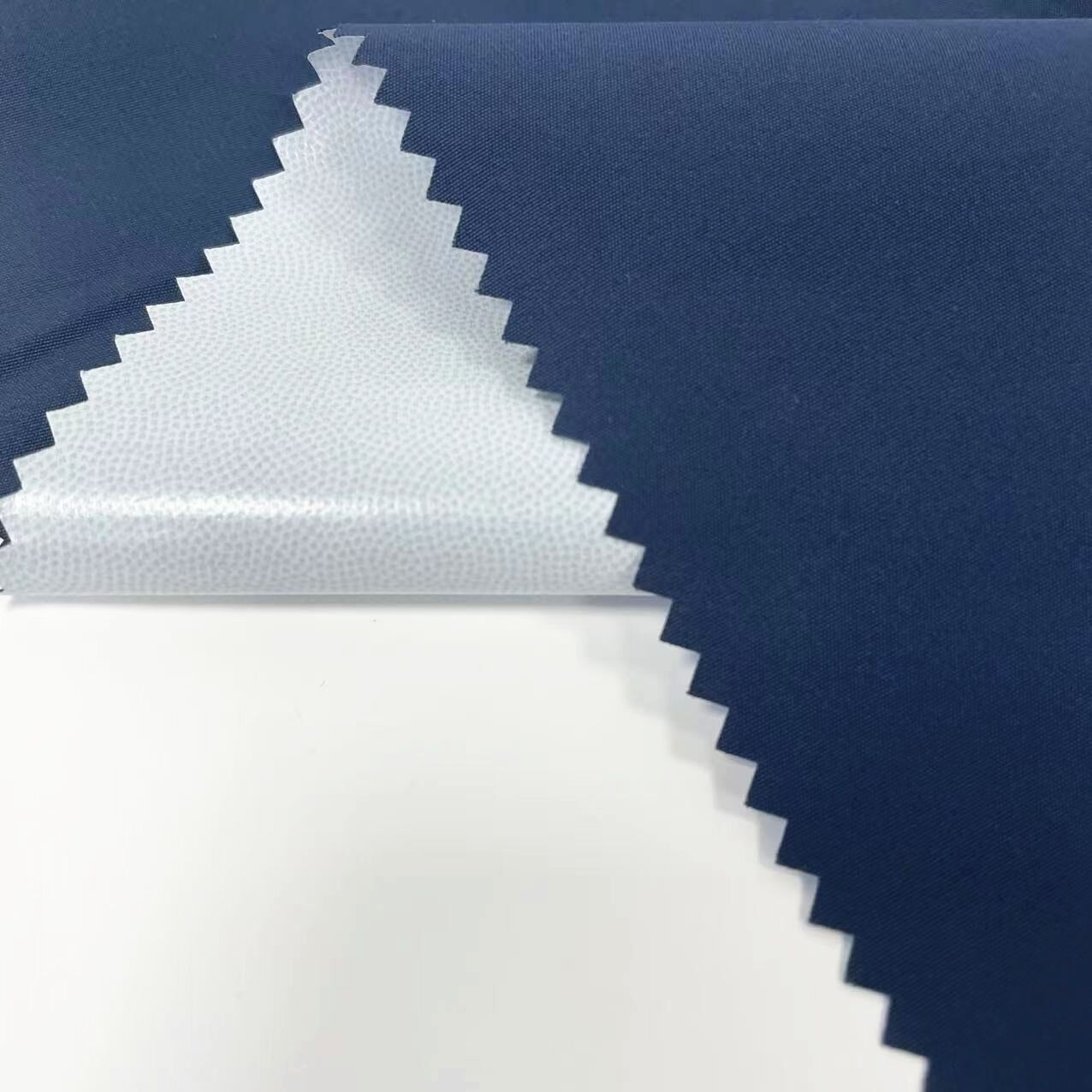

· TPU coated one side and PU coated the other

· 146 cm Usable width

· All orders are approximately 1.48 metres wide (usable width)

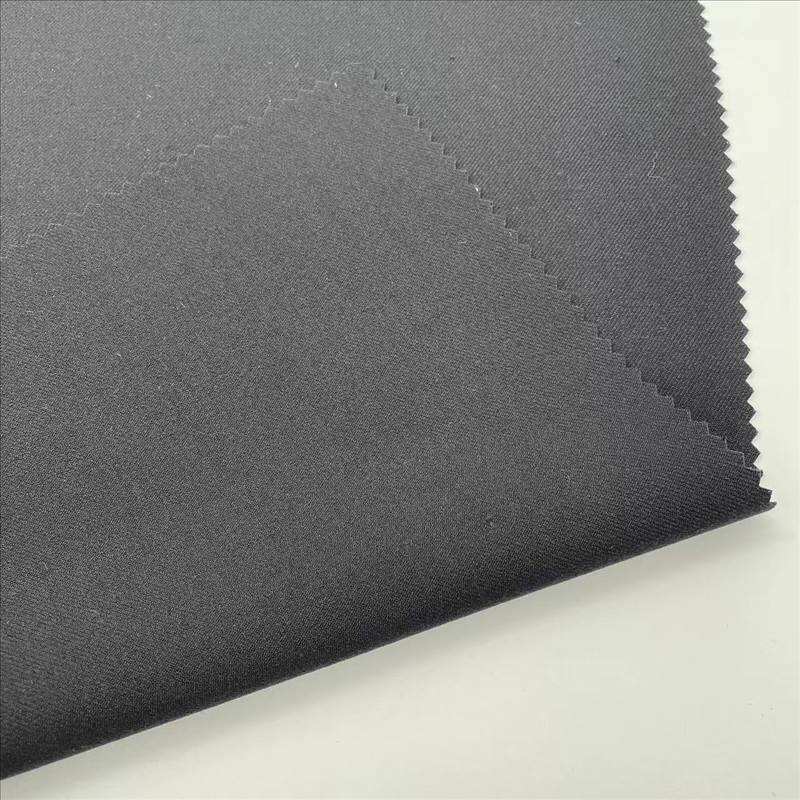

Please note: Due to the manufacturing process, the TPU surface may show streaking. Although this does not affect the performance of the product.

Commonly asked questions.

Which iron do I use for heat-sealing?

We have used both the Jamara Pro Star iron and the Prolux Digital Iron. Or look at the Smaller Electric Iron when dealing with smaller seams and tight areas. Our fabric’s TPU coating is activated at roughly 220 degrees.

What is heat sealing?

All our fabrics have a technical coating called thermoplastic polyurethane (TPU). This coating makes it possible to essentially stick the fabric together without having to mess around with glue! The TPU coating can be activated when heated with hot air or an iron.

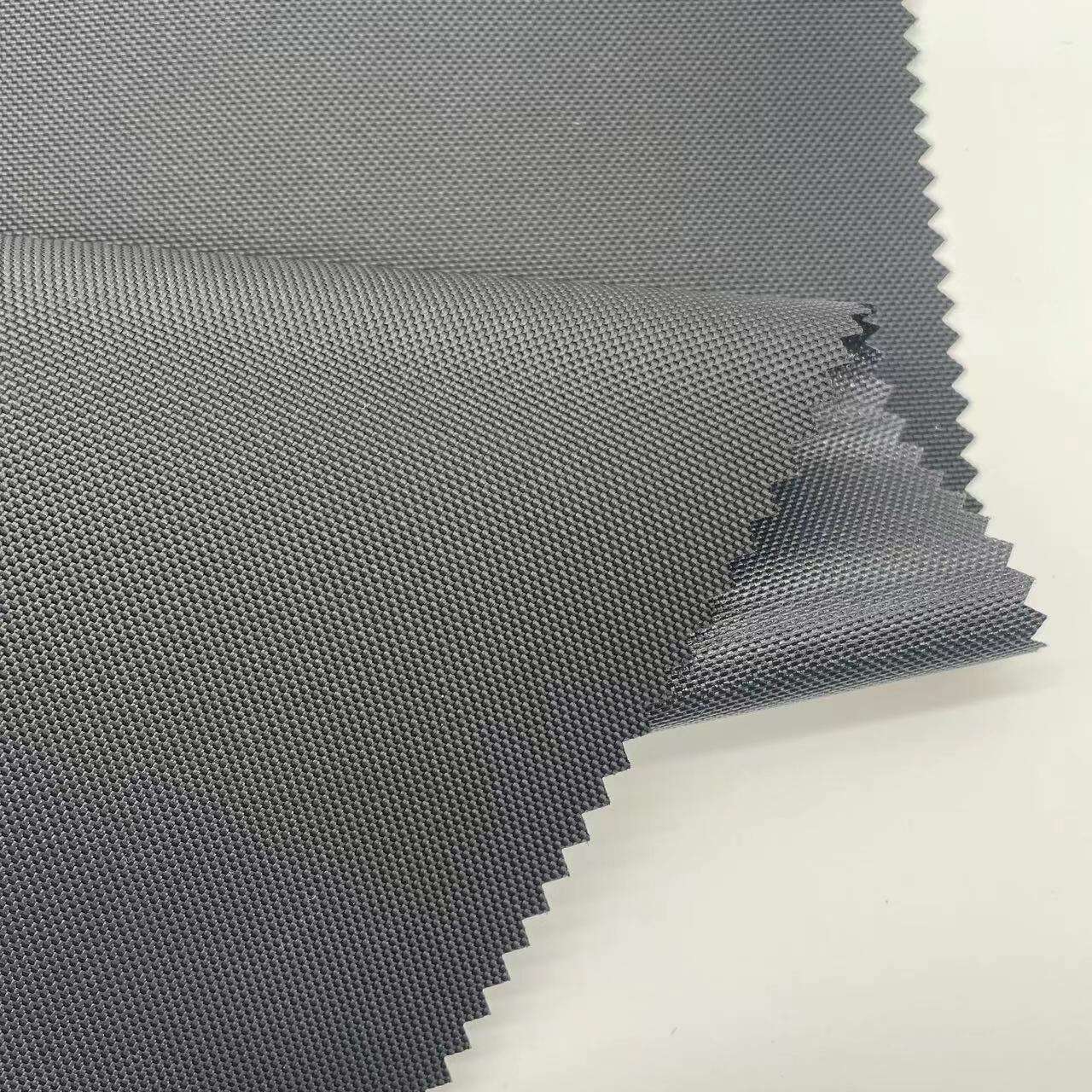

Introducing a breakthrough in technical textile manufacturing: our premium Weldable TPU coated 420D diamond rip-stop fabric. This advanced material is specifically engineered for the future of seam construction, enabling high-frequency welding (HF welding) or heat sealing to create incredibly strong, completely waterproof, and aesthetically superior bonds without the need for traditional stitching. The 420D high-tenacity nylon base provides exceptional tear strength and durability, reinforced by the classic diamond rip-stop pattern that effectively contains damage. The key differentiation is the specialized Thermoplastic Polyurethane (TPU) coating, which is formulated to melt and fuse under precise heat and pressure, creating a permanent, airtight, and watertight seal that is both lighter and more robust than sewn seams.

Our comprehensive service is specifically designed to support your innovation with this advanced material. We offer more than just a product; we provide technical partnership. Our team of experts is available to consult on the optimal welding parameters, machine settings, and design considerations for your specific application, whether for inflatable products, dry bags, marine covers, or high-performance apparel. We guide you from the initial material selection through prototyping and into full production, ensuring a seamless and successful integration of this technology into your manufacturing process.

Quality and consistency are paramount for weldable materials. Our production adheres to a rigorous quality control that focuses on the critical properties for welding. Every batch is tested for coating uniformity, melt flow index (MFI), and peel strength of welded seams, ensuring perfect performance on your production line. We provide detailed material data sheets and can supply certified test reports that verify waterproofness (e.g., 10,000mm hydrostatic head) and weld strength, giving you the empirical data needed to trust this fabric in your most critical applications.

Why Choose Our Weldable Fabric?

Selecting our Weldable TPU coated 420D diamond rip-stop fabric means partnering with a forward-thinking manufacturer that empowers you to create next-generation products. We offer not only a superior material but also the technical support to use it effectively. To fuel your innovation, we support small-batch customization with a low MOQ of 1000 meters, allowing you to develop and market groundbreaking products without a massive initial investment. By choosing us, you gain a reliable source for a fabric that delivers unparalleled waterproof integrity, modern aesthetics, and revolutionary manufacturing efficiency, setting your brand apart in a competitive market.

Applications:

This TPU inflatable fabric can be widely used in inflatable mattresses, air cushions, air cushions, air cushions, tents, waterproof bags, drying bags, storage bags, waterproof bags, drying bags, outdoor backpacks, map bags, Ipad bags, phone bags, basins , Buckets, water bags, inflatable tents, airbags, inflatable helium remote control airships, hot air balloons, etc.

The first application of TPU is as an environmentally friendly substitute for PVC, so the TPU waterproof fabric can be used wherever PVC fabrics are used.

Specifications:

| Yarn: | 420D*420D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | Diamond | Visual |

| Density(in): | W50*F38 | ISO 7211/2 |

| Finishing: | DWR+TPU coating | Visual |

| Thickness: | 0.45MM | ASTM D 1777 |

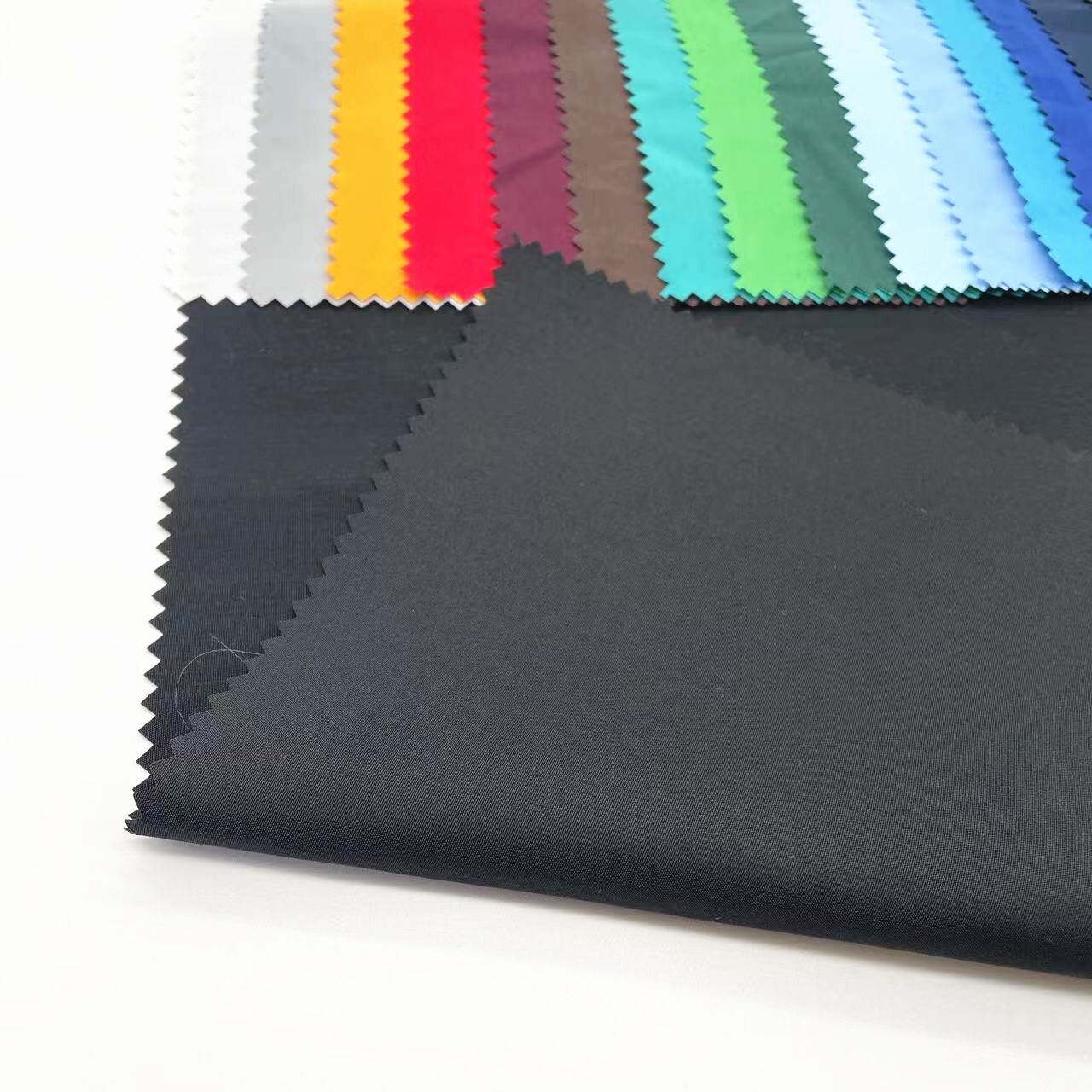

| Width: | 146CM | ASTM D 3774 |

| Weight: | 300GSM | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:20LBF, F: 18LBF | ASTM D1424 |

| Tensile strength 1'': | W:450LBF, F:430LBF | ASTM D5034-21 Grab test |

| Hydrostatic Pressure: | 1000MM | AATCC TM127 |

Competitive Advantage:

High Quality

Factory direct sell price

Durable water repellent

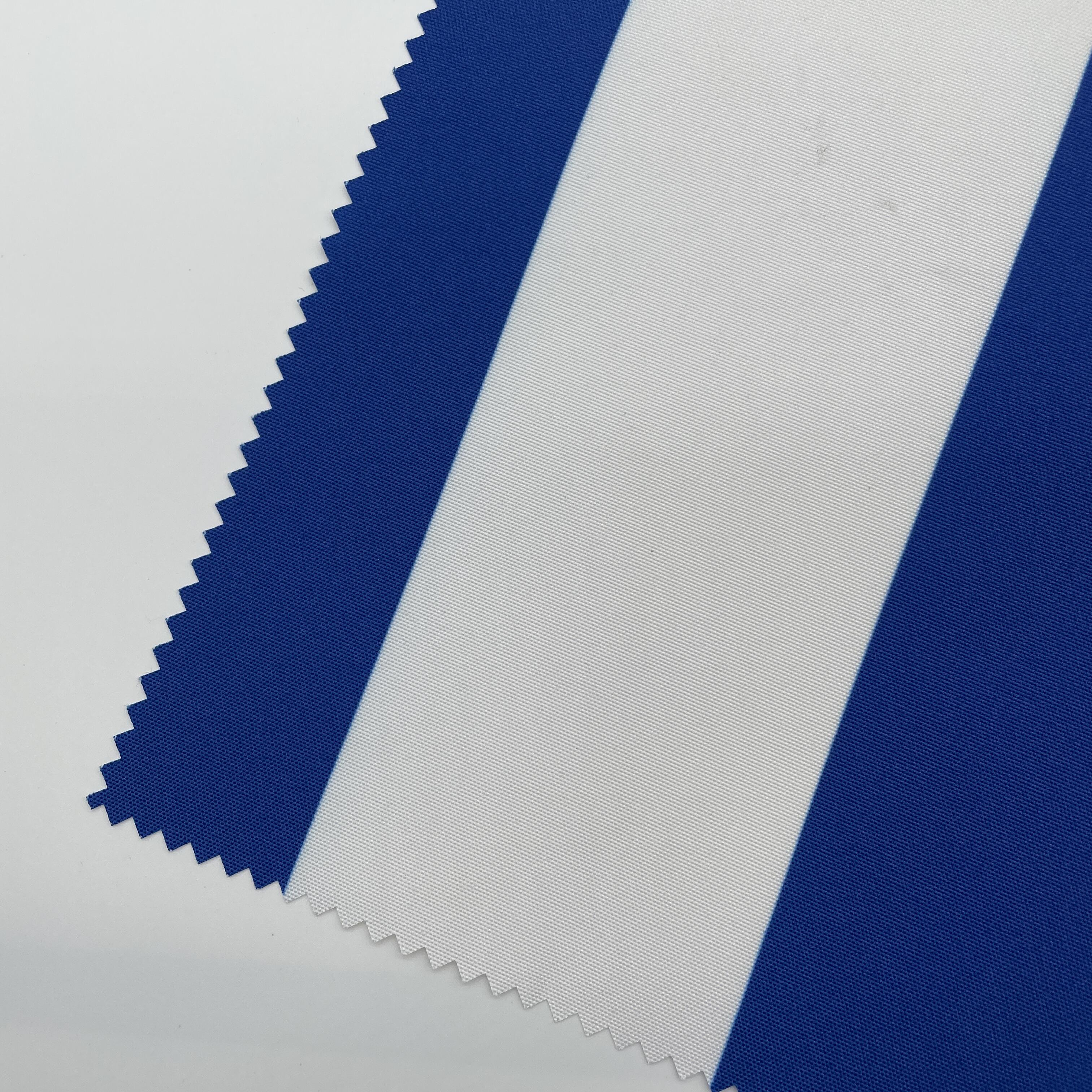

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ