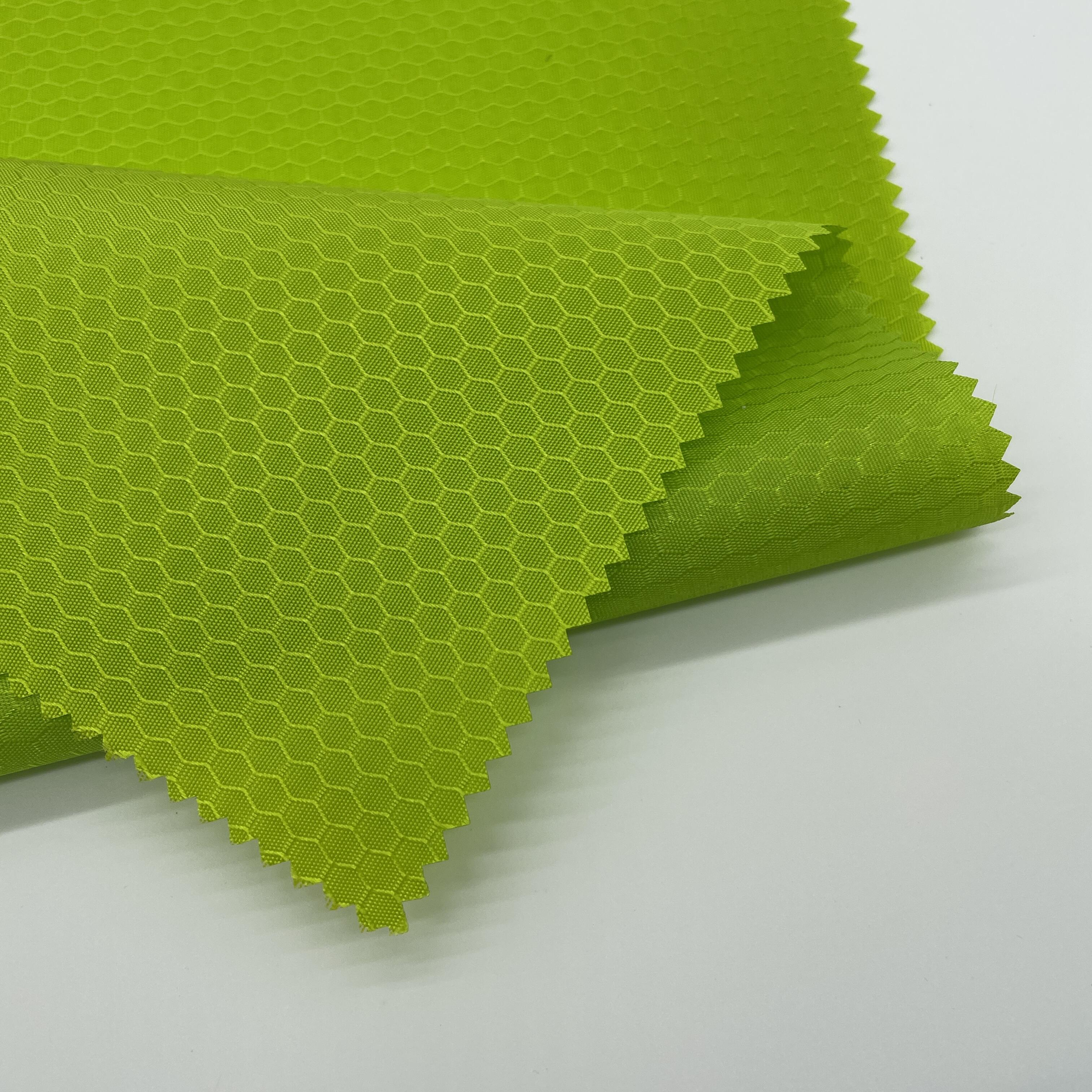

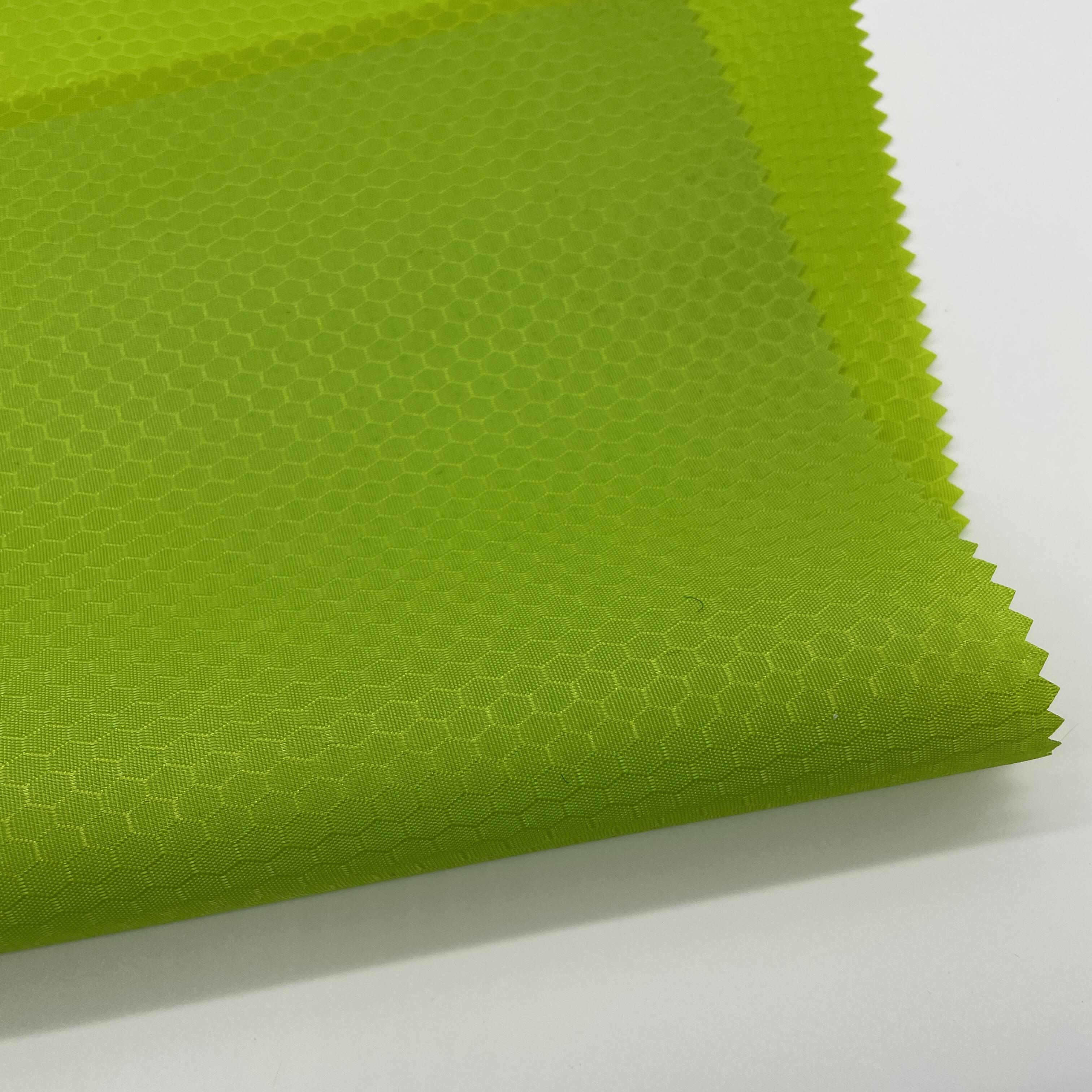

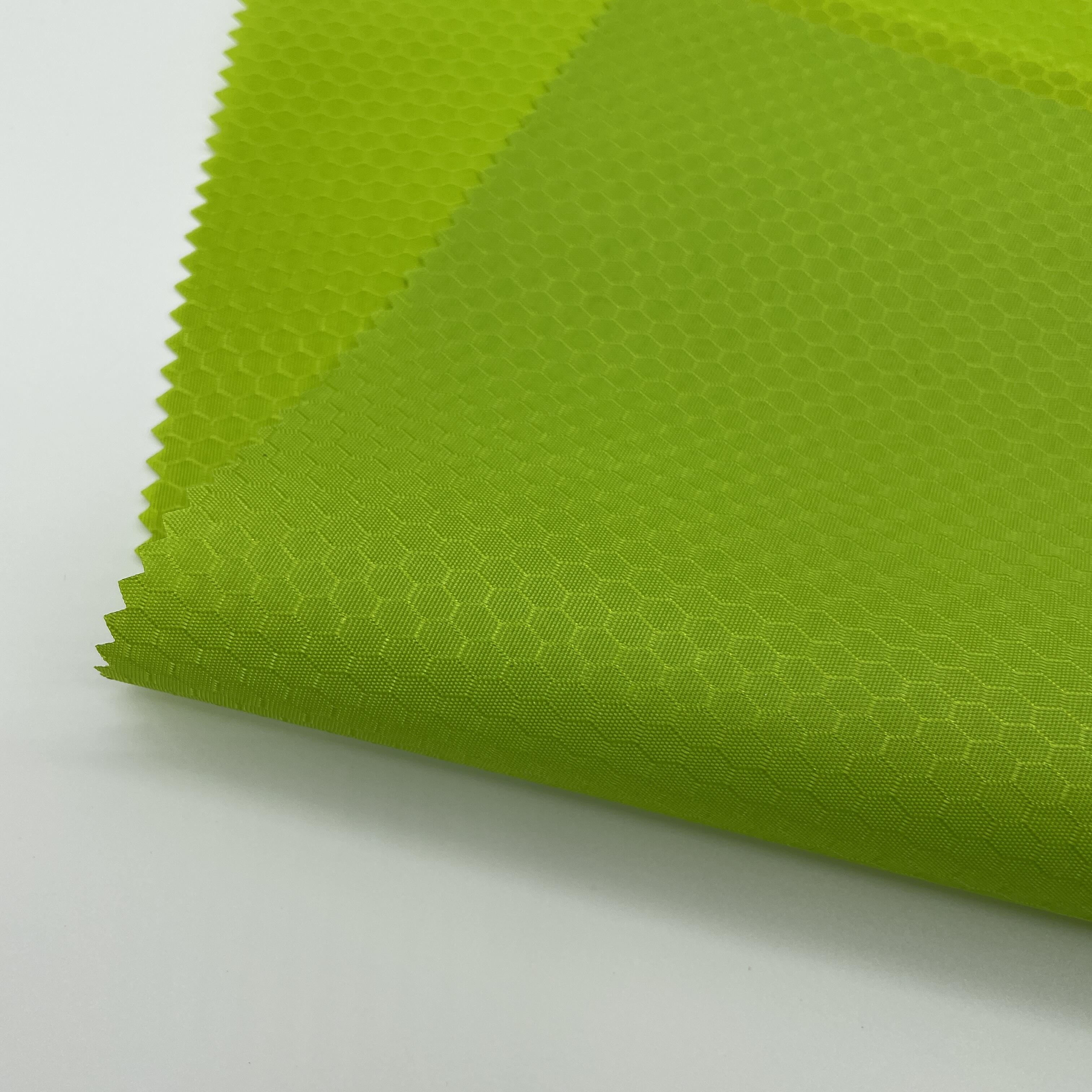

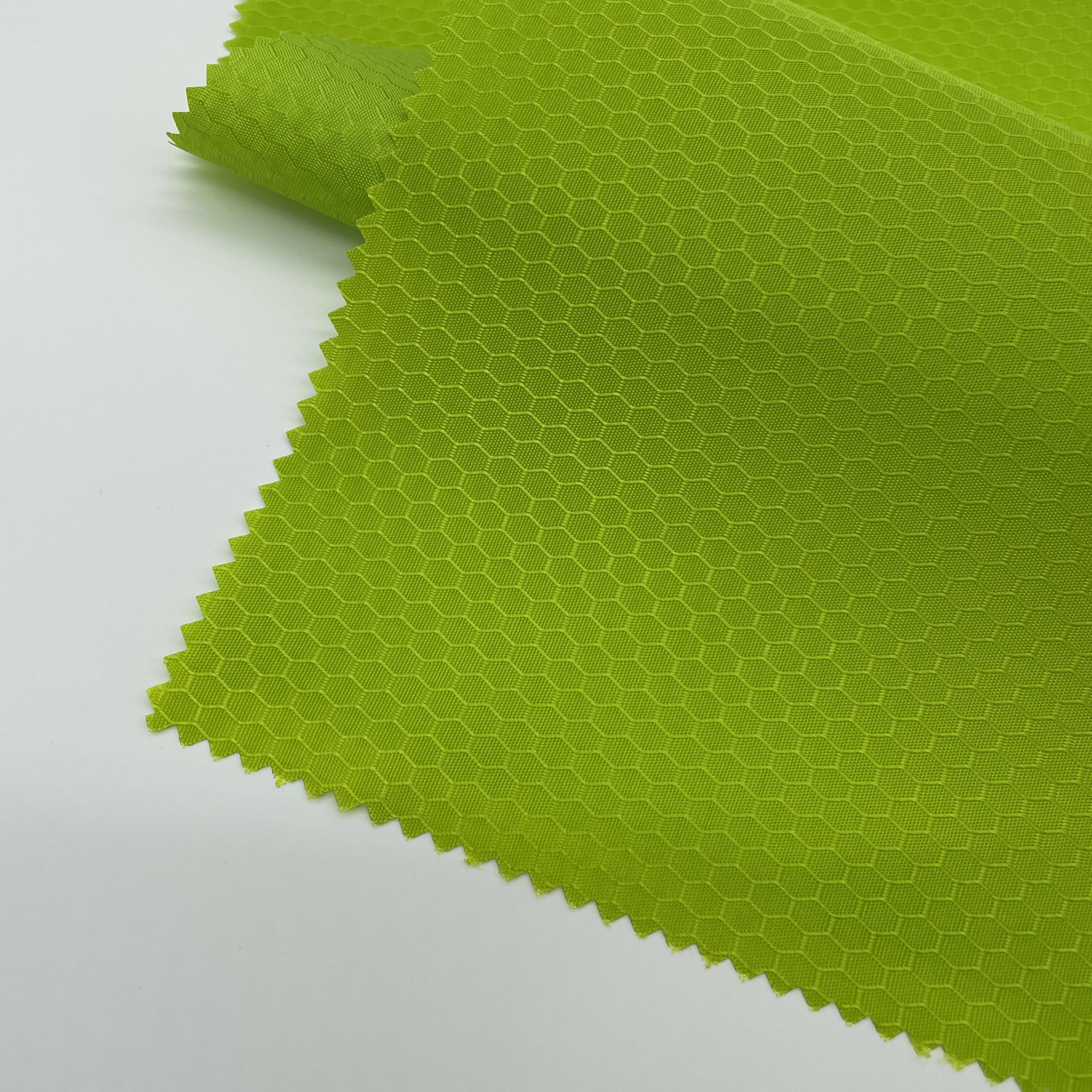

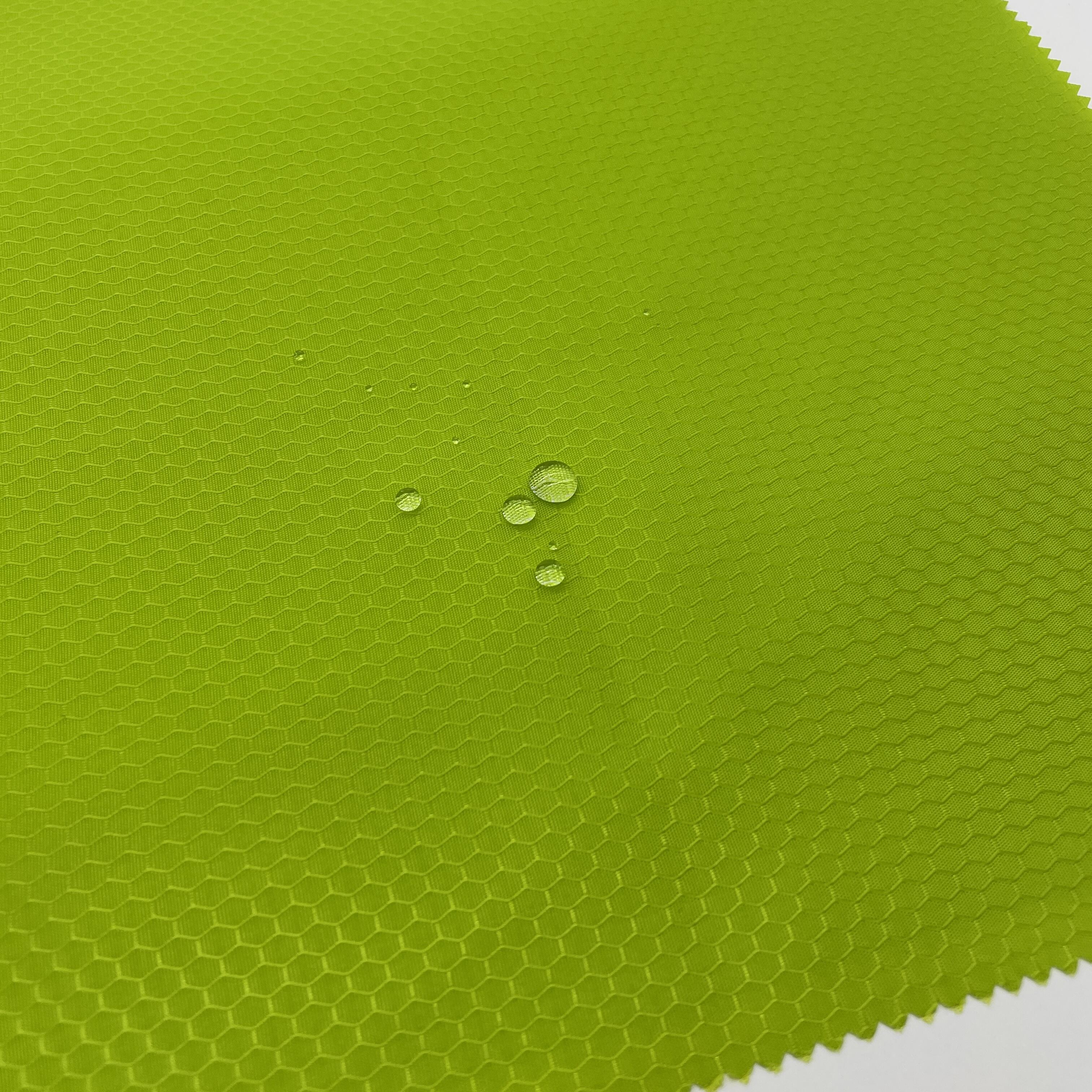

PU coating 210D nylon hexagon rip-stop fabric

| Content: | Nylon |

| Coating: | PU(Polyurethane) |

| Country of origin: | China |

| Weaving: | Hexagon |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 100yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

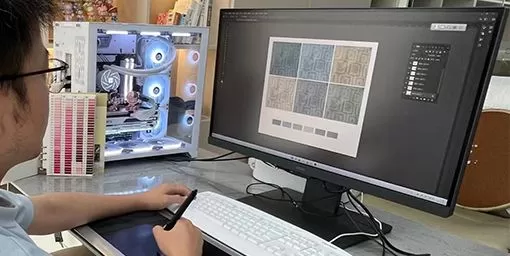

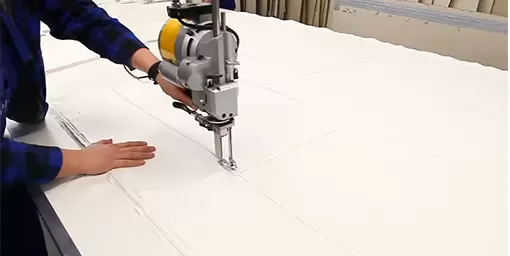

- Process flow

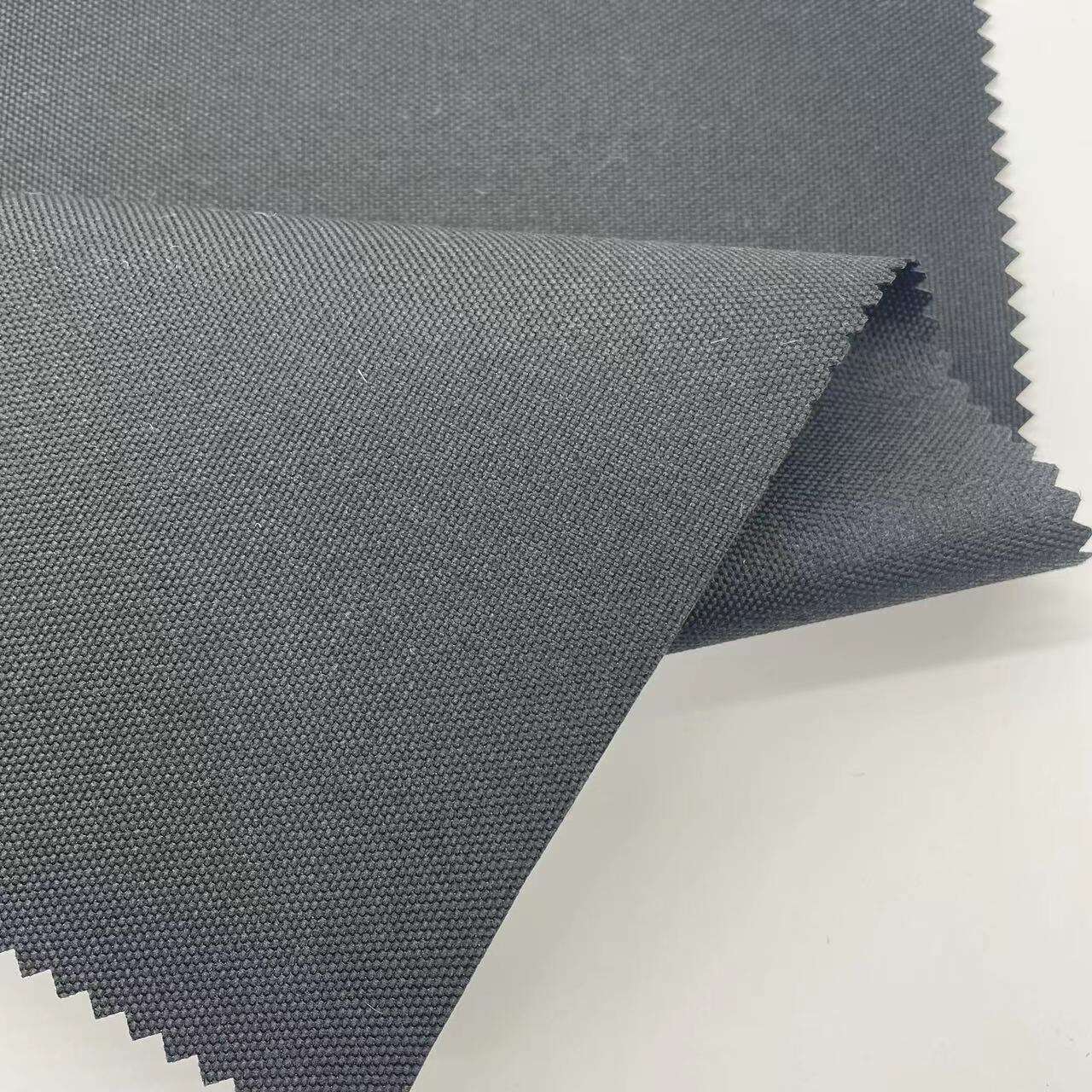

- Related products

- Inquiry

Parameter

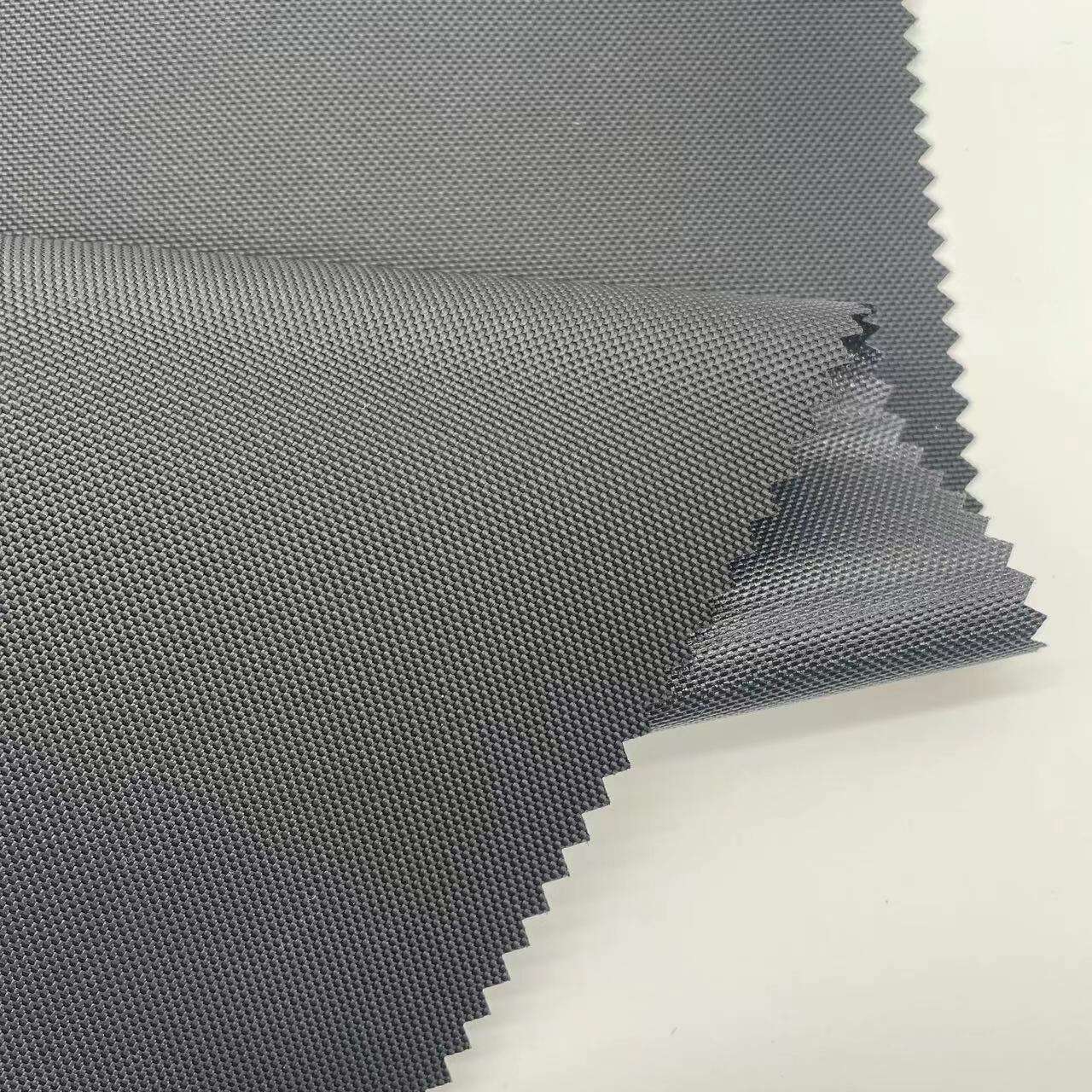

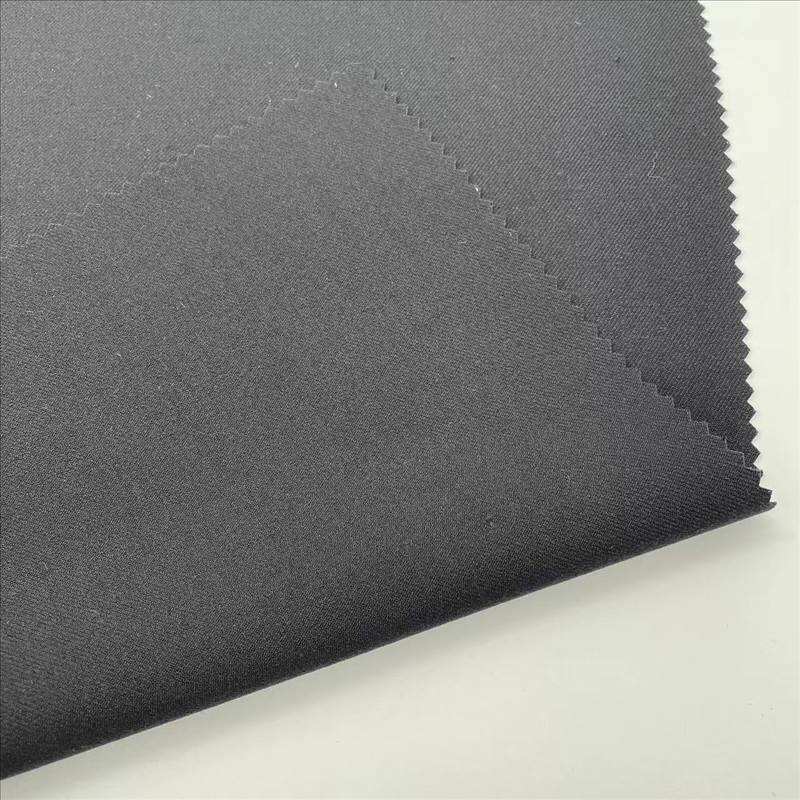

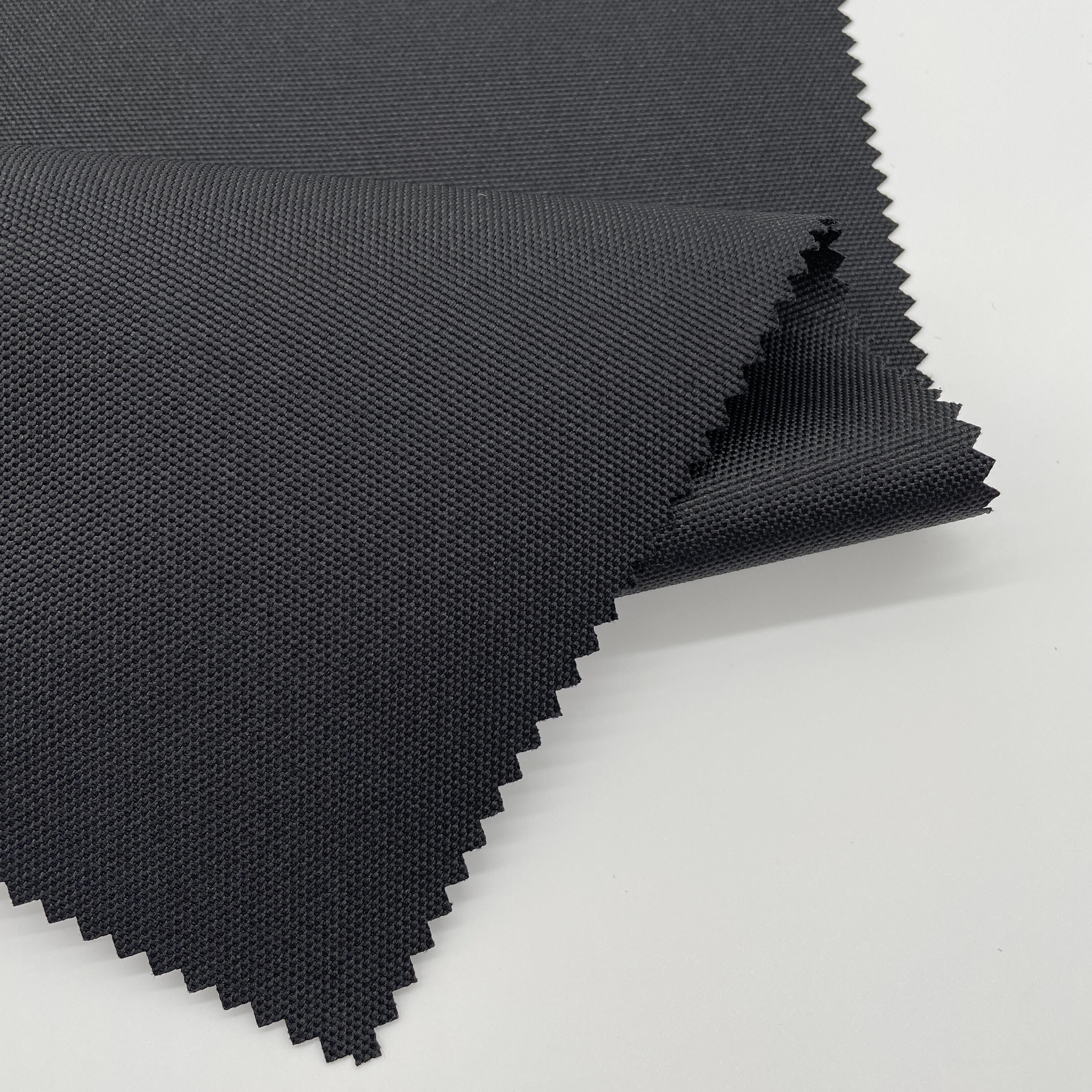

210D Nylon hexagon rip-stop Oxford is a lightweight, flexible, tear resistance fabric. It has a hexagon rip-stop weave which makes the fabric tear resistant. Our 210D hexagon Nylon fabric is coated with urethane.

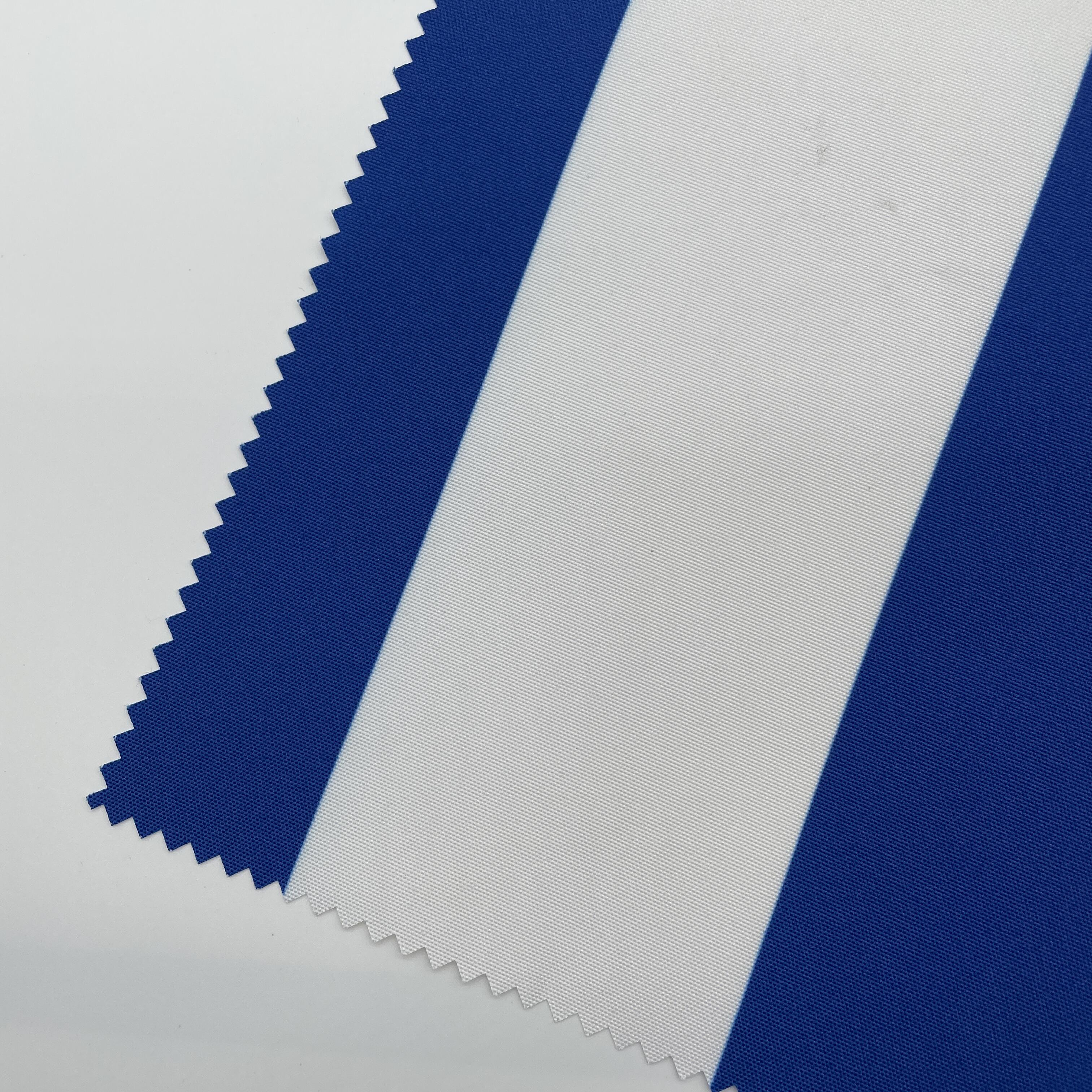

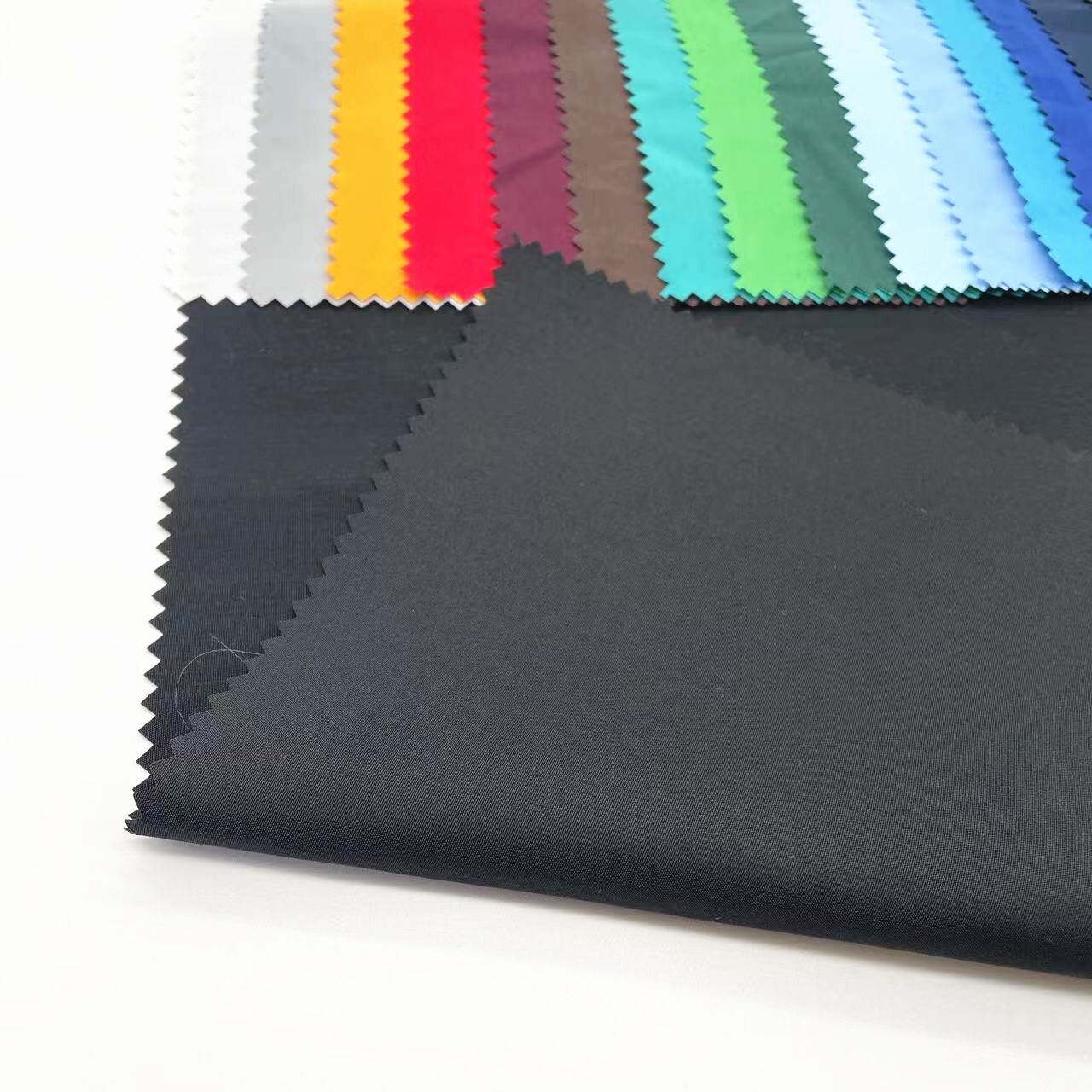

210D nylon oxford has many designs like hexagon, squares, diamonds, plaid, dobby, etc. Different designs means the fabric weaving and style is different. 210D nylon oxford not only can be coated with PU, also can be coated with TPU, PVC or TPE for different using.

210D Nylon Hexagon Rip-stop Oxford Fabric

In the world of advanced technical textiles, innovation in weave structure represents the next frontier in performance enhancement. Our 210D Nylon Hexagon Rip-stop Oxford fabric introduces a groundbreaking approach to material durability and aesthetic distinction. Unlike conventional grid patterns, this engineered textile features an intricate hexagon rip-stop weave that provides superior tear and snag resistance across multiple stress points. This innovative construction makes it an exceptional choice for applications where maximum durability meets modern design, including technical outdoor equipment, specialized protective cases, high-performance workwear, and advanced tactical systems.

The unique properties of this 210D Nylon Hexagon Rip-stop Oxford fabric derive from its sophisticated manufacturing process. The hexagonal weave pattern distributes mechanical stress more efficiently than traditional rip-stop designs, creating a fabric that maintains its structural integrity under extreme conditions. The combination of 210 denier high-tenacity nylon yarns and the tight Oxford weave construction results in a material that offers exceptional abrasion resistance, dimensional stability, and overall durability. This advanced textile provides reliable performance without compromising on flexibility or comfort, making it ideal for applications requiring both protection and mobility.

Our Commitment to Technical Excellence and Customer Success

We deliver more than just innovative materials – we provide comprehensive solutions backed by rigorous quality assurance and exceptional service.

Precision Manufacturing and Quality Verification: Our production process adpples the highest technical standards, with every batch undergoing meticulous quality control checks. We employ advanced testing protocols to verify key performance characteristics including tear strength, abrasion resistance, and weave integrity. Customers receive detailed certification packages with their orders, including optional third-party test reports that validate the exceptional quality of our 210D Nylon Hexagon Rip-stop Oxford fabric. This transparent approach to quality assurance ensures complete confidence in your material selection.

Collaborative Development Process: We've established a customer-centric service framework that supports your product development journey from concept to completion. Our technical specialists work closely with clients throughout the sampling and prototyping phases, providing expert guidance on material utilization and performance optimization. Understanding the needs of innovators and growing brands, we maintain a flexible manufacturing approach with a low Minimum Order Quantity (MOQ) of 1,000 meters, enabling you to pursue specialized projects and market testing with reduced initial investment.

Partnership Advantages: Selecting our 210D Nylon Hexagon Rip-stop Oxford fabric means accessing specialized expertise in advanced textile applications. Our team provides comprehensive technical support, sharing insights on manufacturing best practices and performance characteristics that can enhance your final product's market appeal and functional reliability.

Discover the next generation of rip-stop technology with our innovative 210D Nylon Hexagon Rip-stop Oxford fabric. Contact us today to request sample materials and technical documentation, and learn how our cutting-edge textile solutions can elevate your product offerings while maintaining the highest standards of quality and performance.

Applications:

210D Nylon hexagon Oxford is great for outdoor gear, sporting goods, and even medical equipment.

Some common uses for this fabric include: slip covers for patio furniture or grills, flags and banners, drawstring bags, lining for bags, cases, tents, and hammocks.

Specifications:

| Yarn: | 210D*210D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | Hexagon | Visual |

| Density(in): | W101*F50 | ISO 7211/2 |

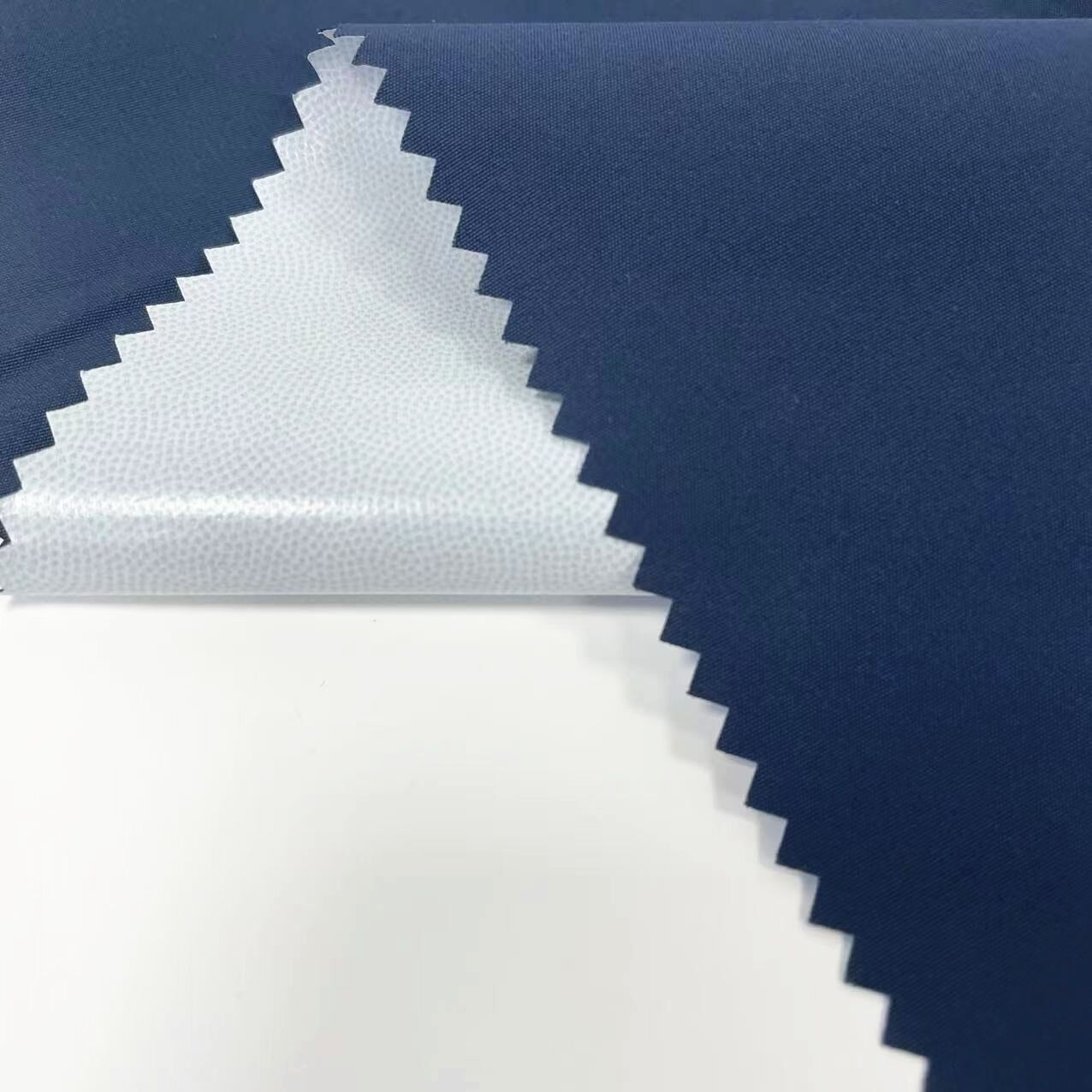

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.27MM | ASTM D 1777 |

| Width: | 60'' | ASTM D 3774 |

| Weight: | 150GSM | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:5LBF, F: 4LBF | ASTM D1424 |

| Tensile strength 1'': | W:170LBF, F:160LBF | ASTM D5034-21 Grab test |

| Hydrostatic Pressure: | 800MM | AATCC TM127 |

Competitive Advantage:

High Quality

Factory direct sell price

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ