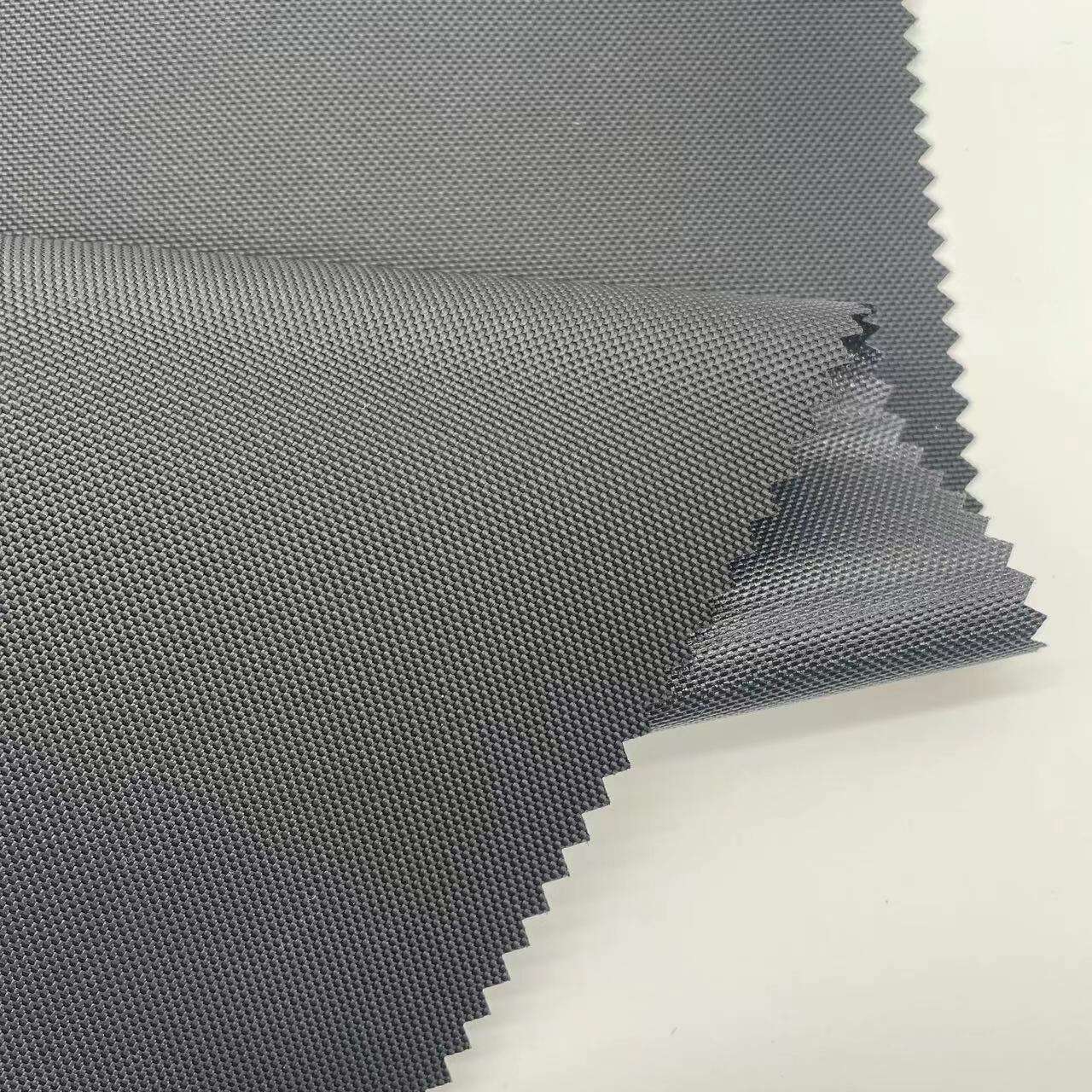

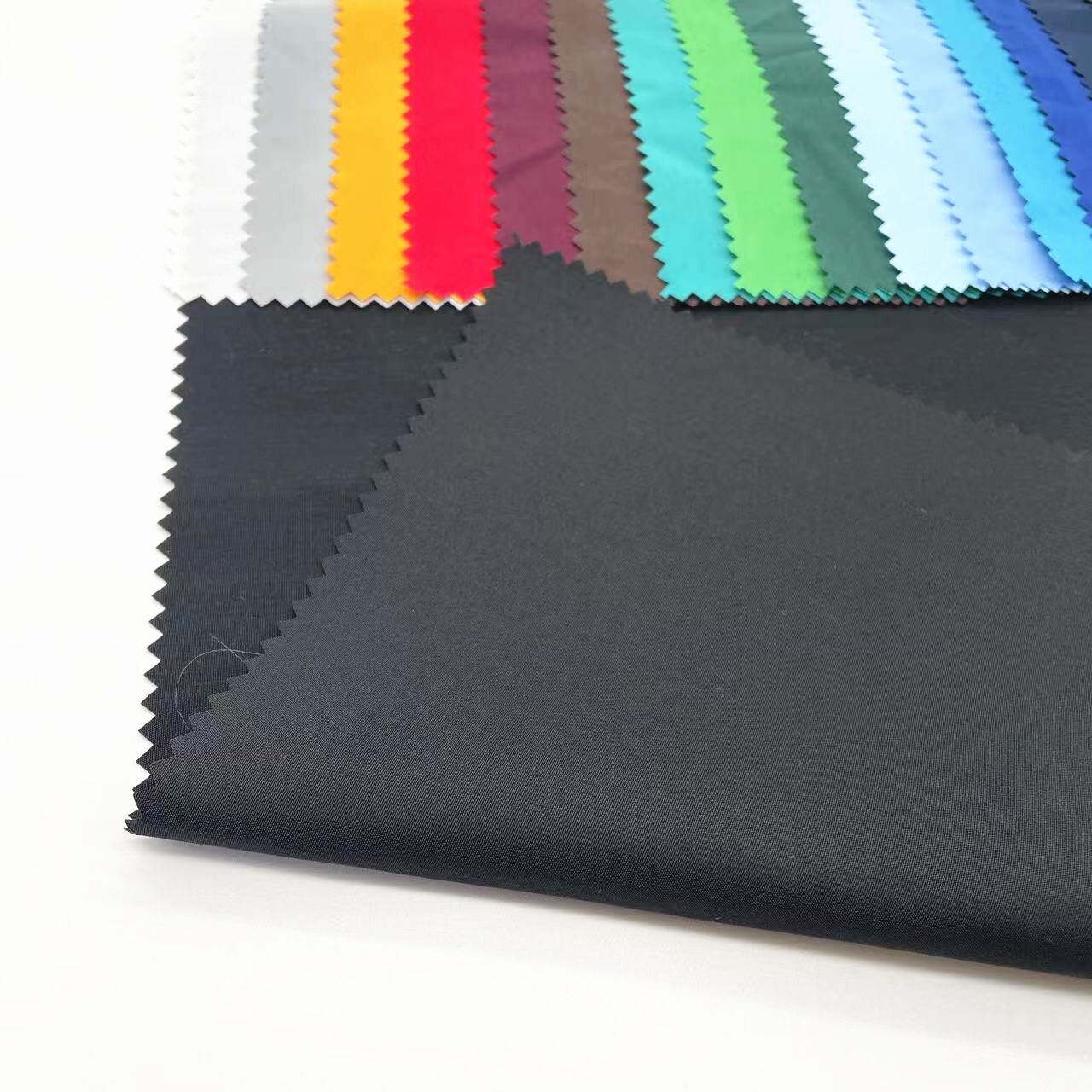

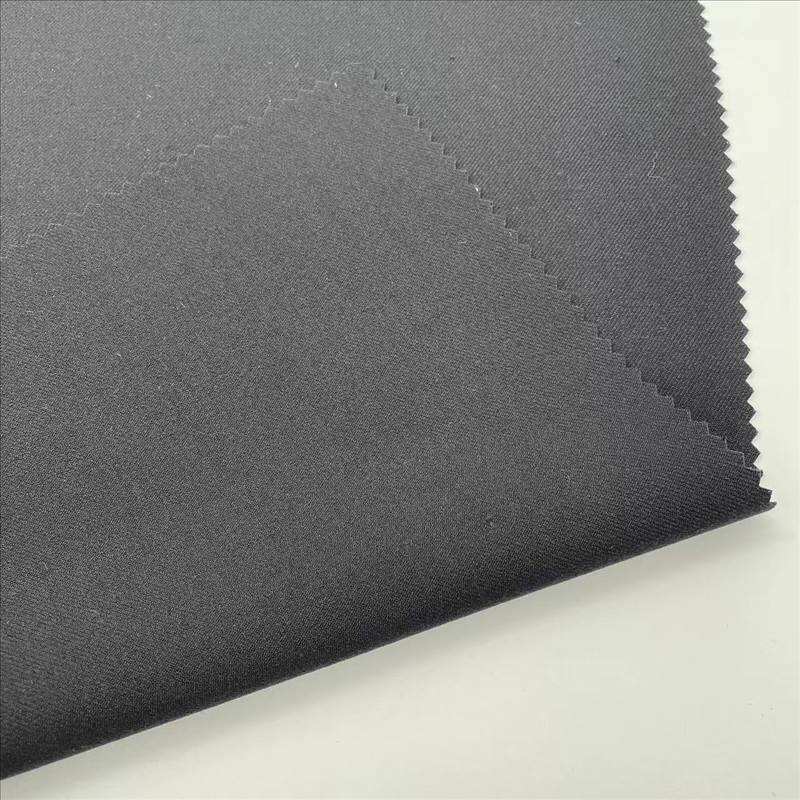

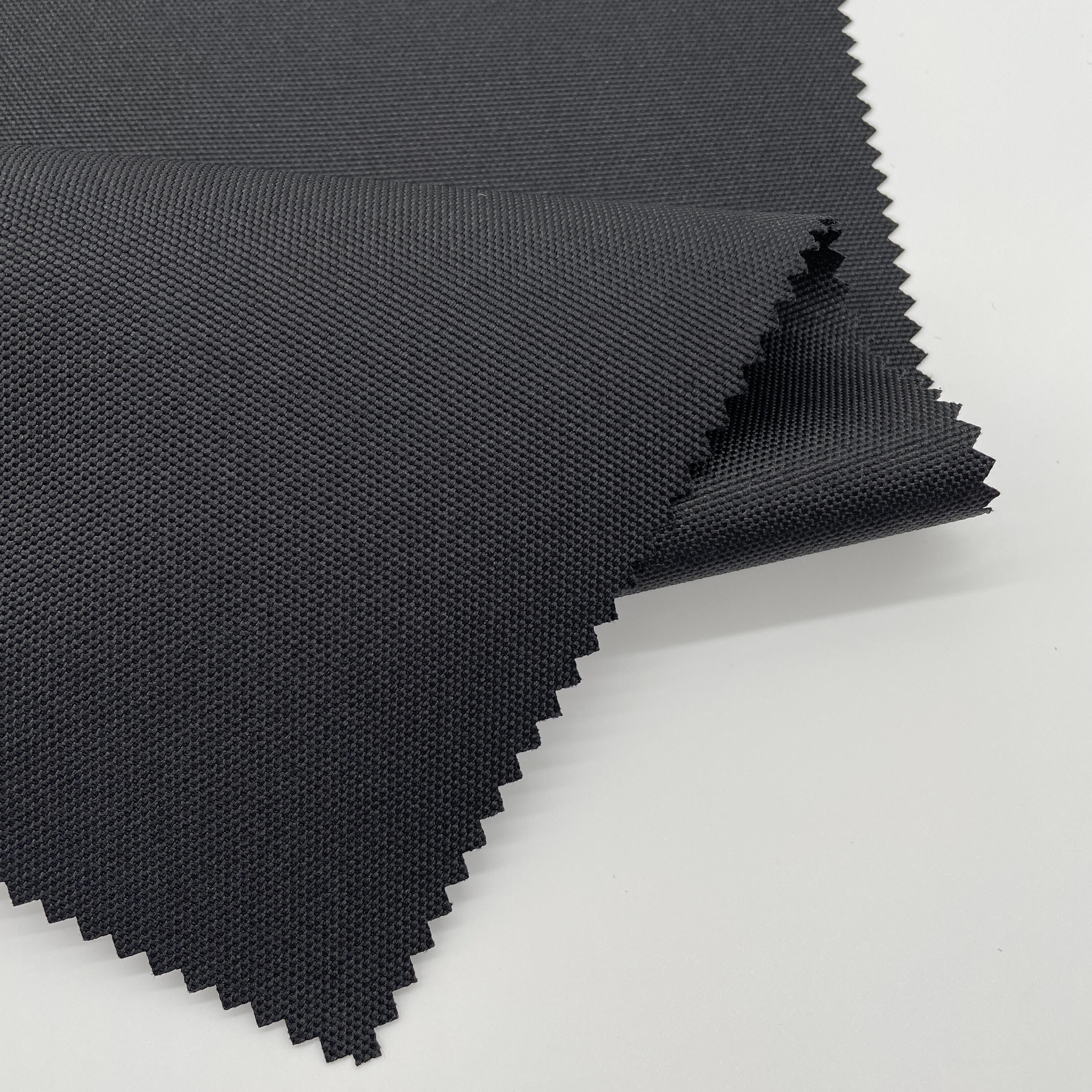

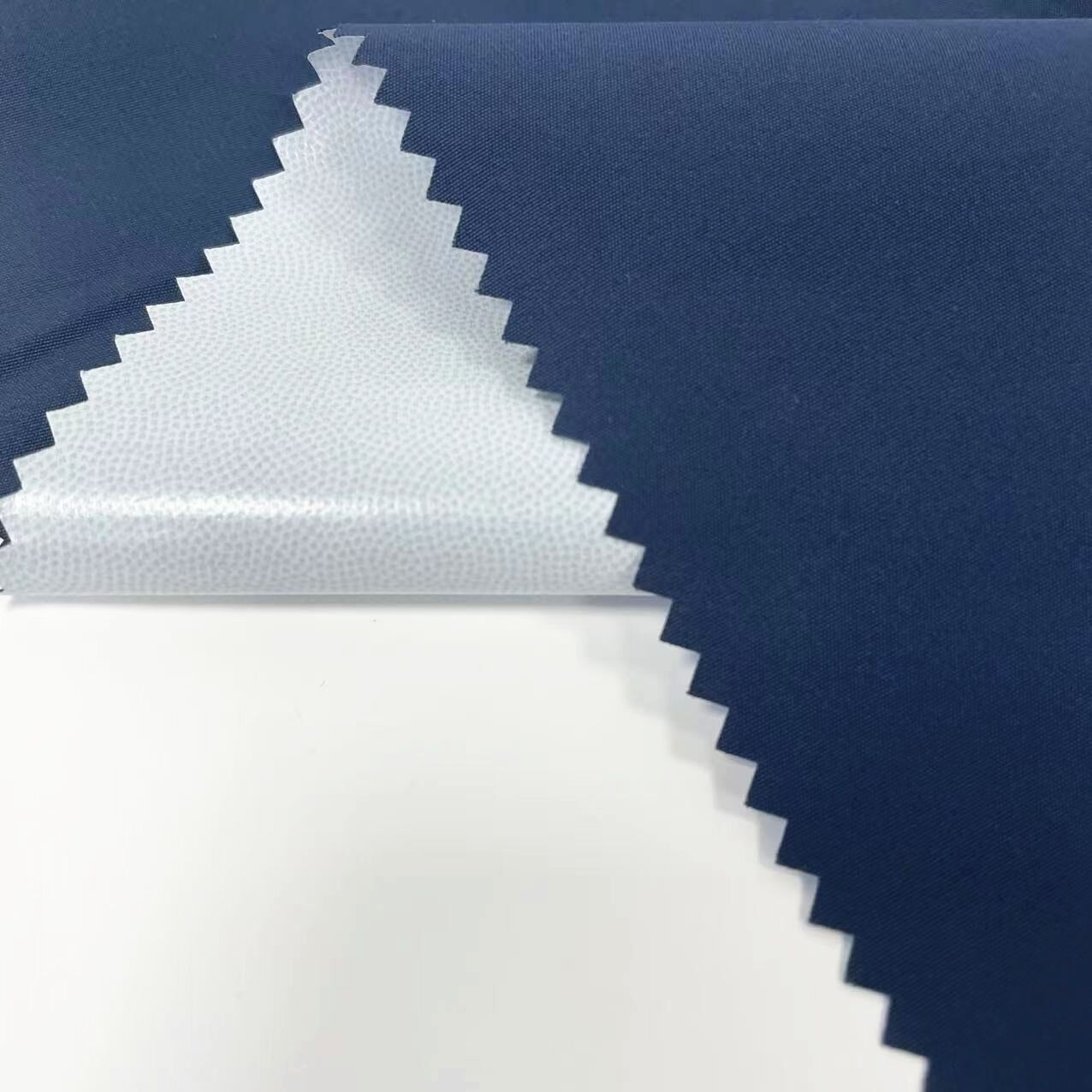

Polyester woven cationic/melange 4 way stretch fabric with DWR finishing

| Content: | 92%Polyester, 8%Spandex |

| Finishing: | Piece dyeing+DWR |

| Country of origin: | China |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

| Available membranes: | PU/TPU/TPE/ePTFE |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

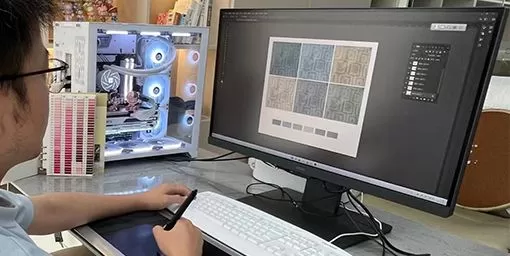

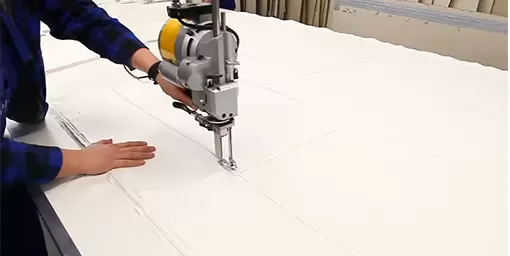

- Process flow

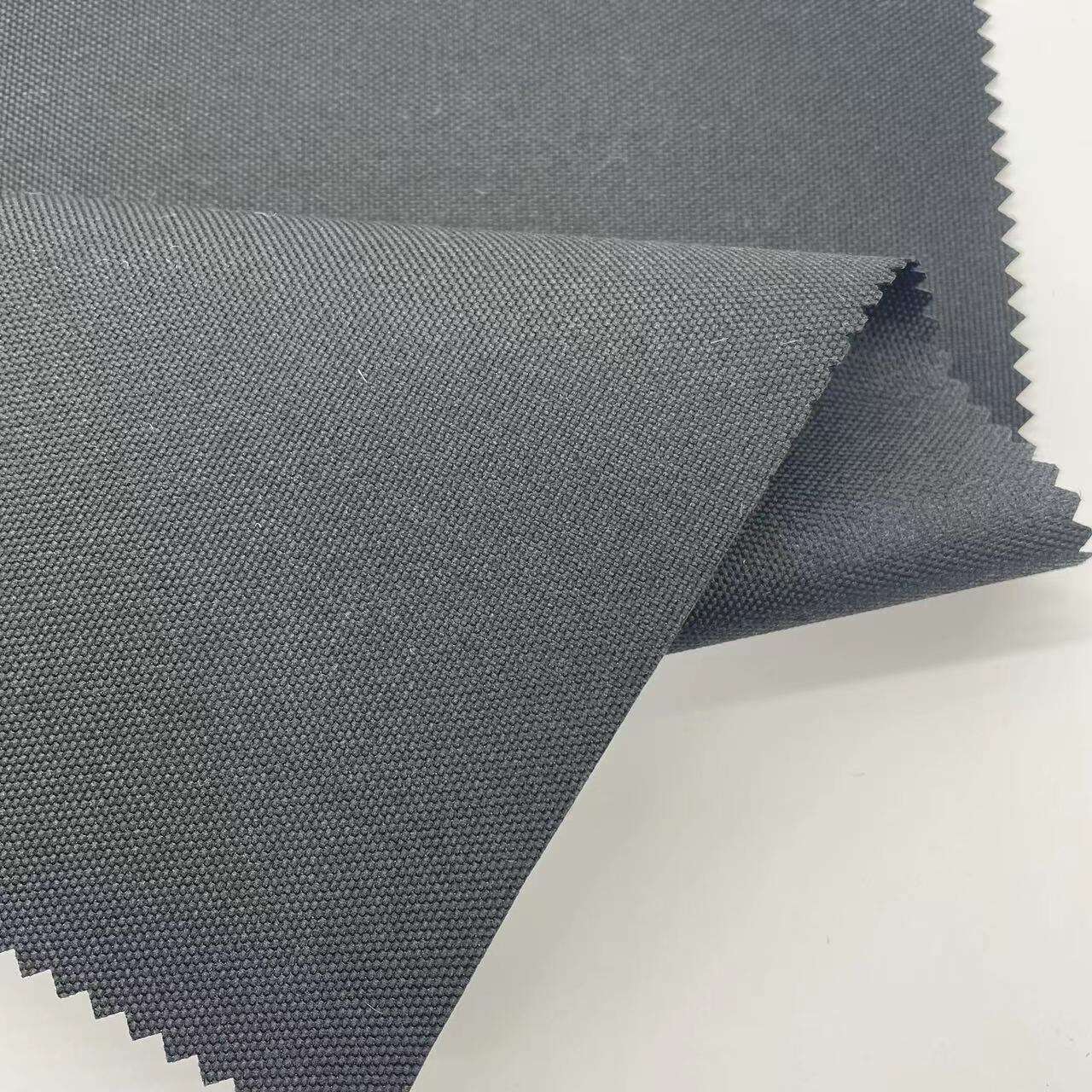

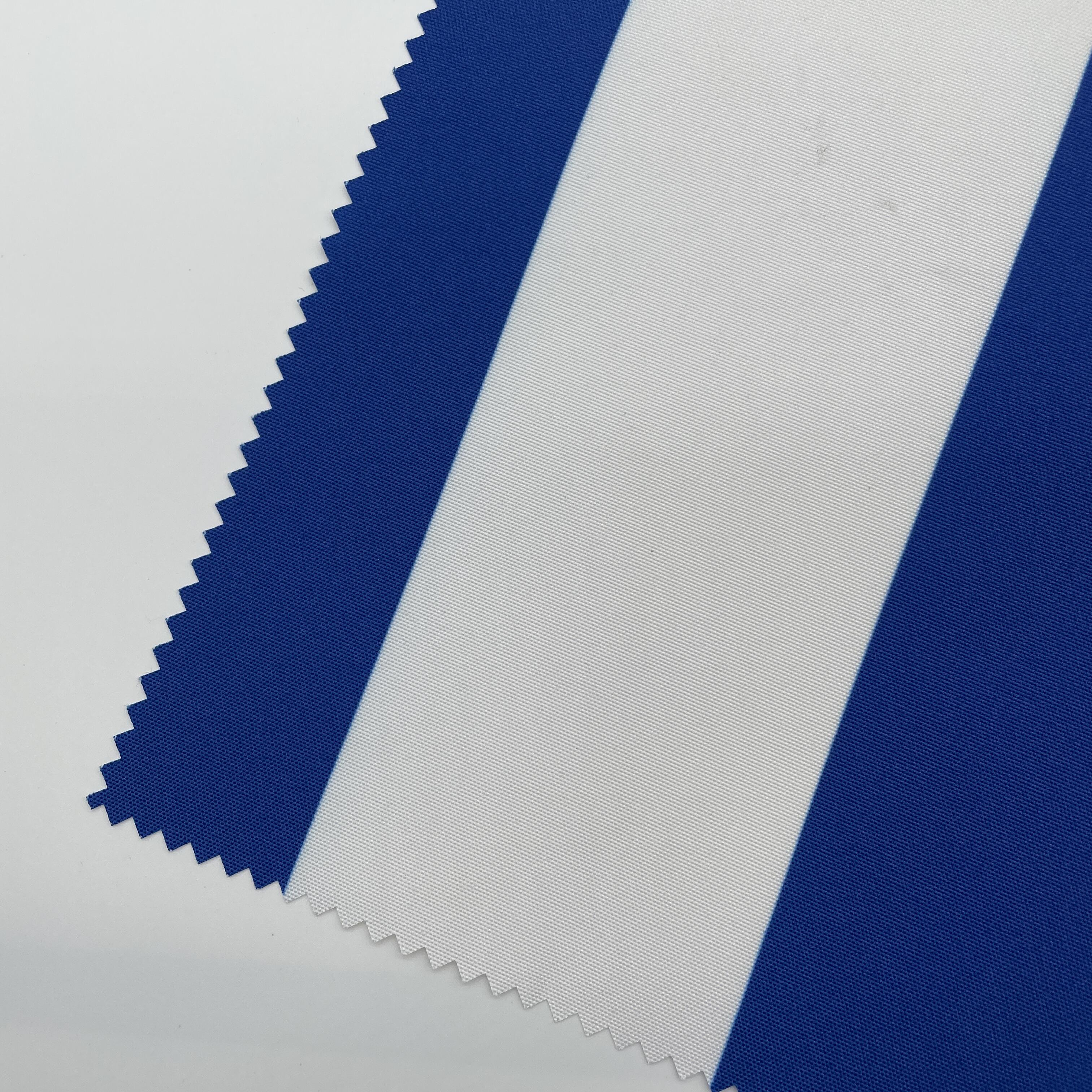

- Related products

- Inquiry

Parameter

Stretch Woven fabrics are often used in activewear, soft shells, and gear in the outdoor apparel and military/tactical industries. These fabrics are made with a blend of fibers that allow them to stretch and move with the body. The benefits of using stretch woven fabric include comfort, durability, breathability, performance, and versatility.

Our Stretch Woven Fabrics are various blends of nylon or polyester and spandex. Finishing these fabrics with DWR or wicking helps to make these fabrics durable and resistant to the elements.

Applications:

Stretch woven fabrics are most common used forplate carriers, pants, jackets, and various other outerwear or military/tactical

Specifications:

| Yarn: | 100D+40D*100D+40D | ISO 7211/5 |

| Composition: | 92%Polyester, 8%Spandex | ASTM D629 |

| Construction: | Plain | Visual |

| Weave: | Woven | ISO 7211/2 |

| Finishing: | Piece dyeing+DWR | Visual |

| Width: | 57/58’ | ASTM D 3774 |

| Weight: | 150GSM | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

Competitive Advantage:

High Quality

Durable water repellent

Excellent color fastness

Strong waterproof

Great breathability

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ