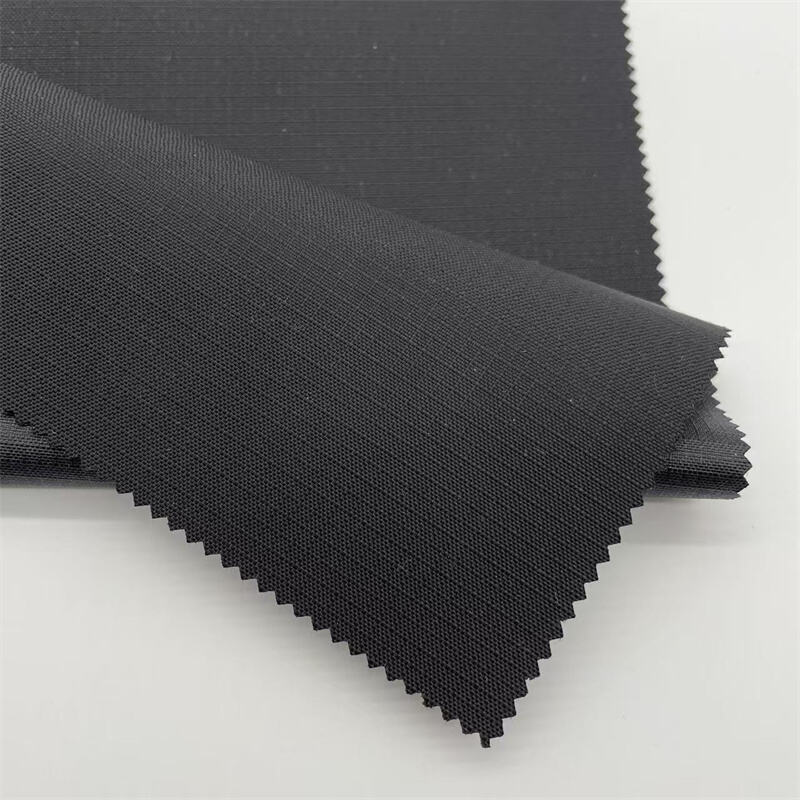

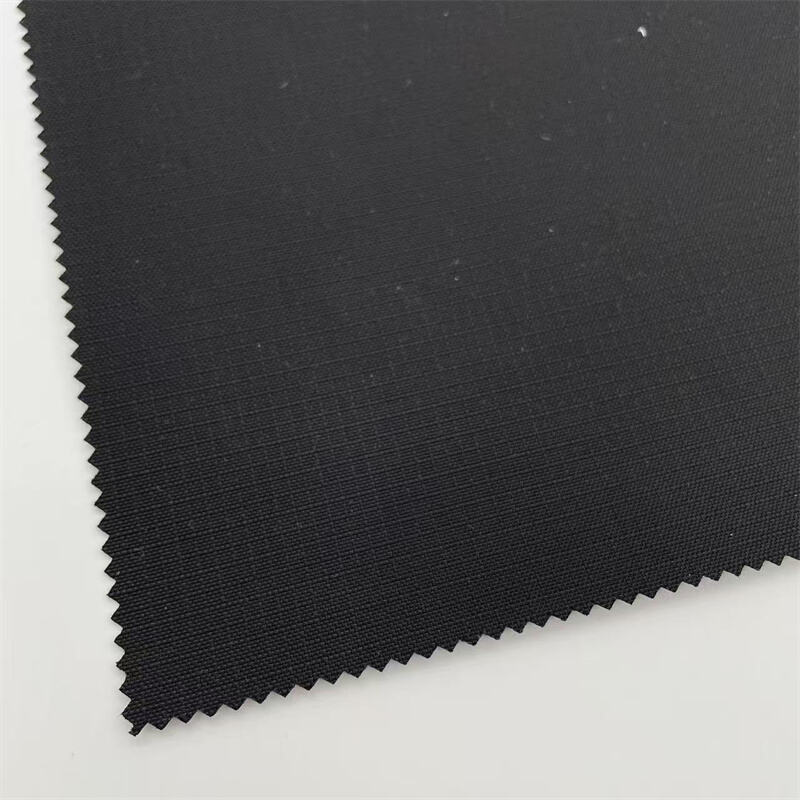

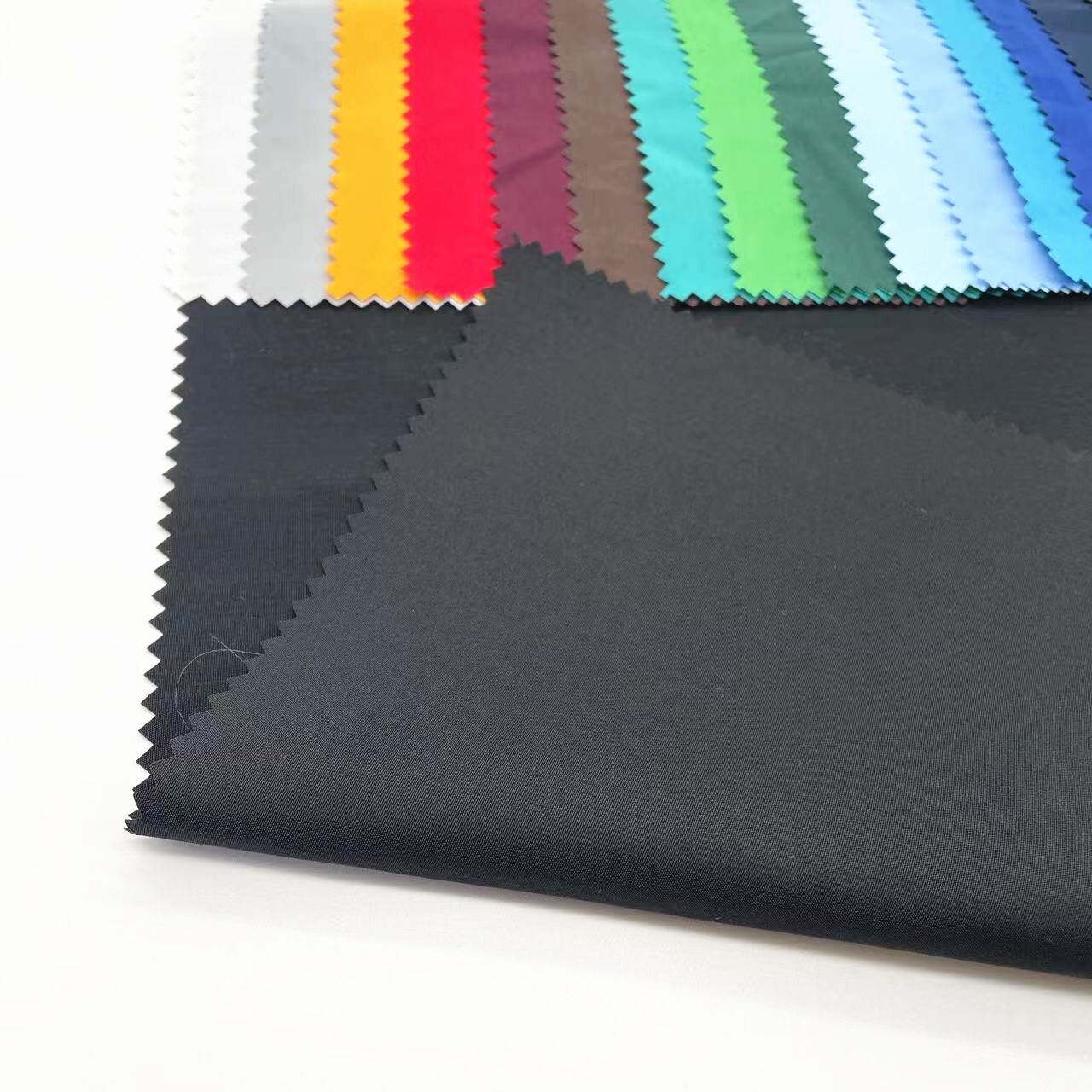

PFAS free Water repellent 210D nylon cordura 3MM rip-stop fabric with 2 pass PU coating

| Content: | Nylon |

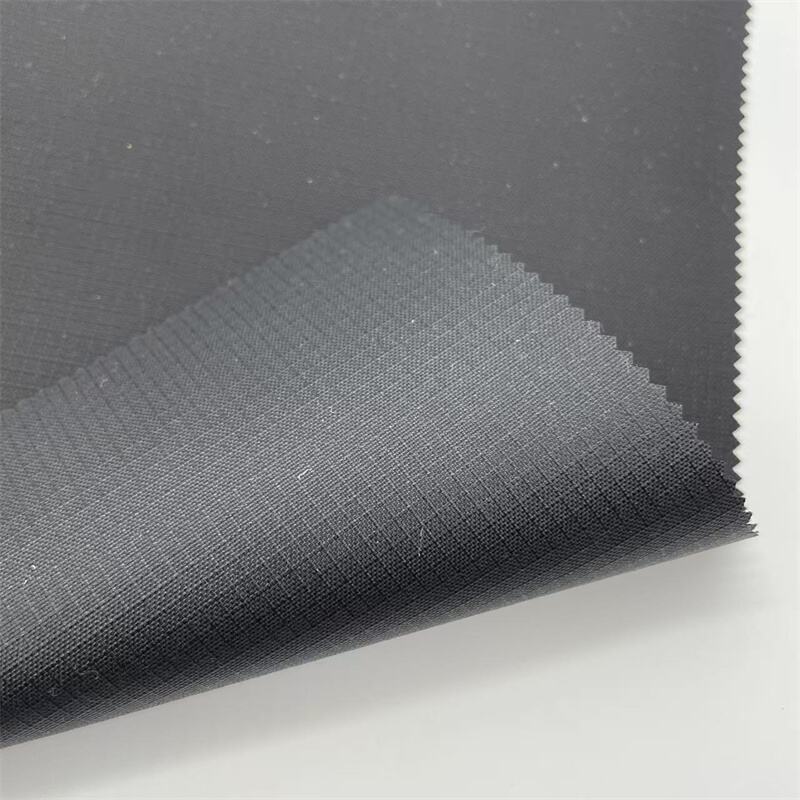

| Coating: | PU(Polyurethane) |

| Country of origin: | US |

| Weaving: | 3MM rip-stop |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

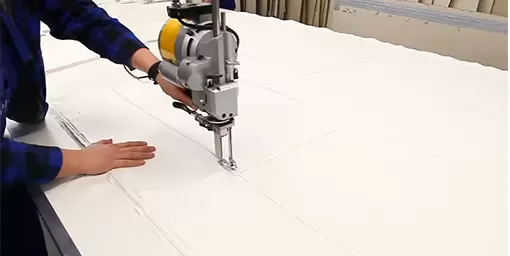

- Process flow

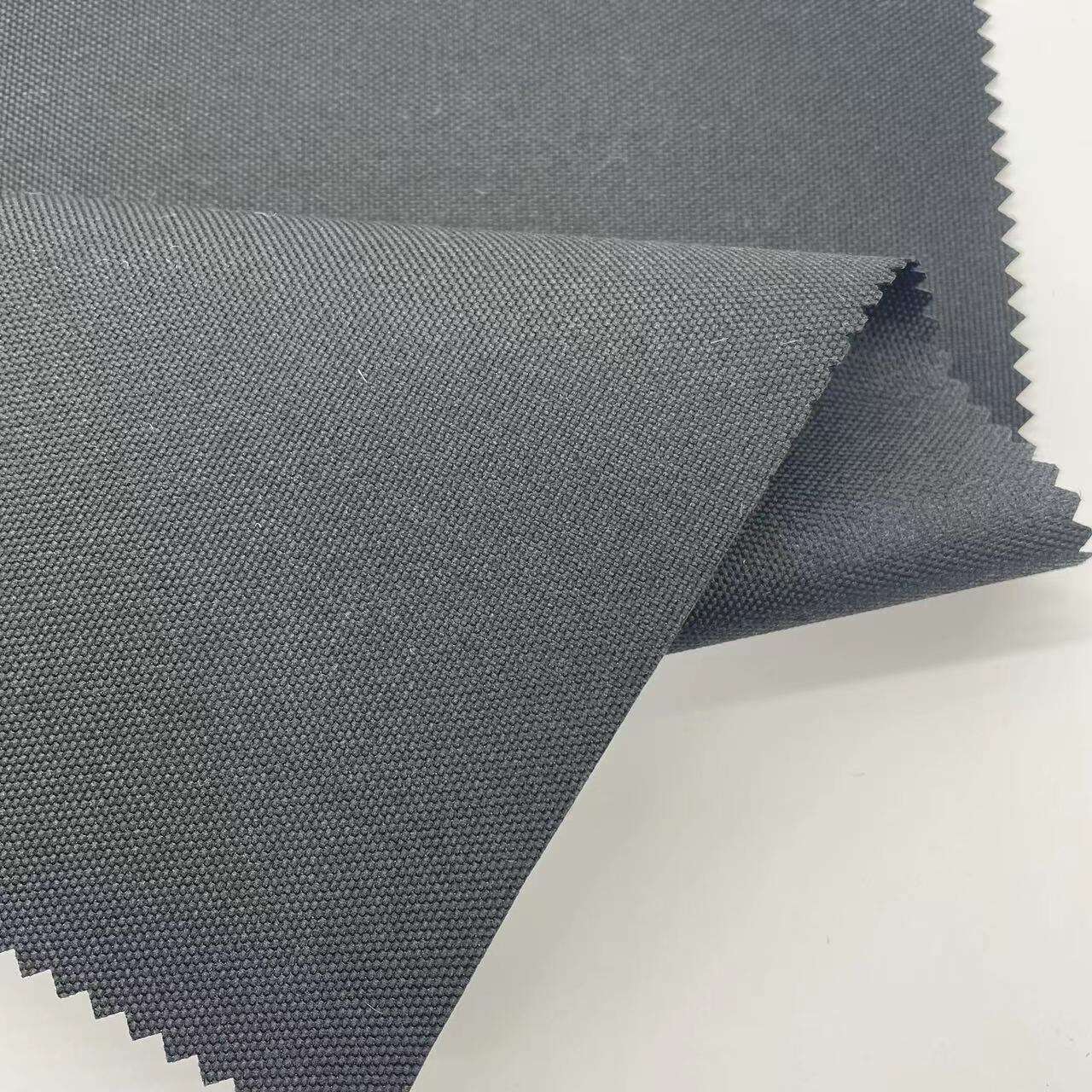

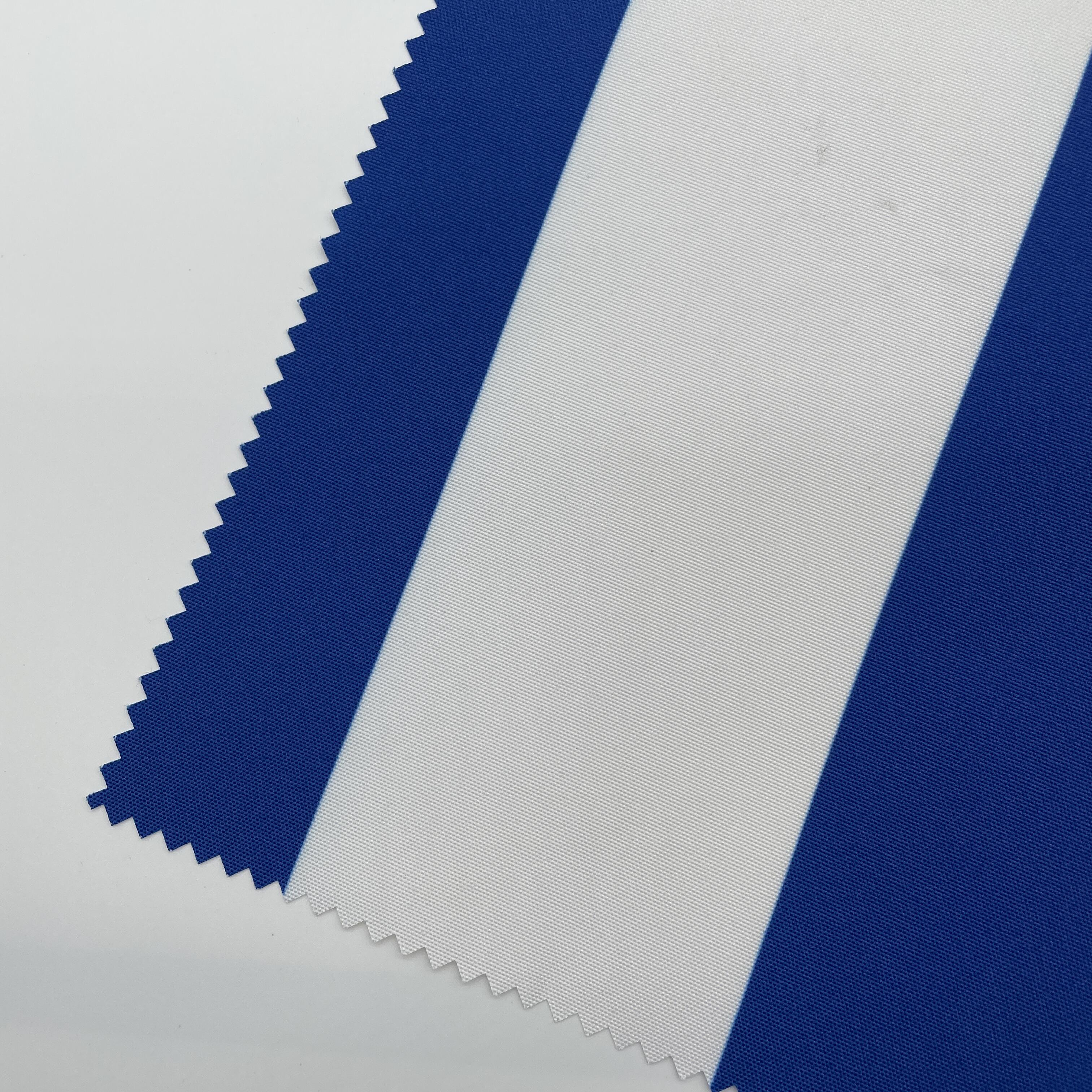

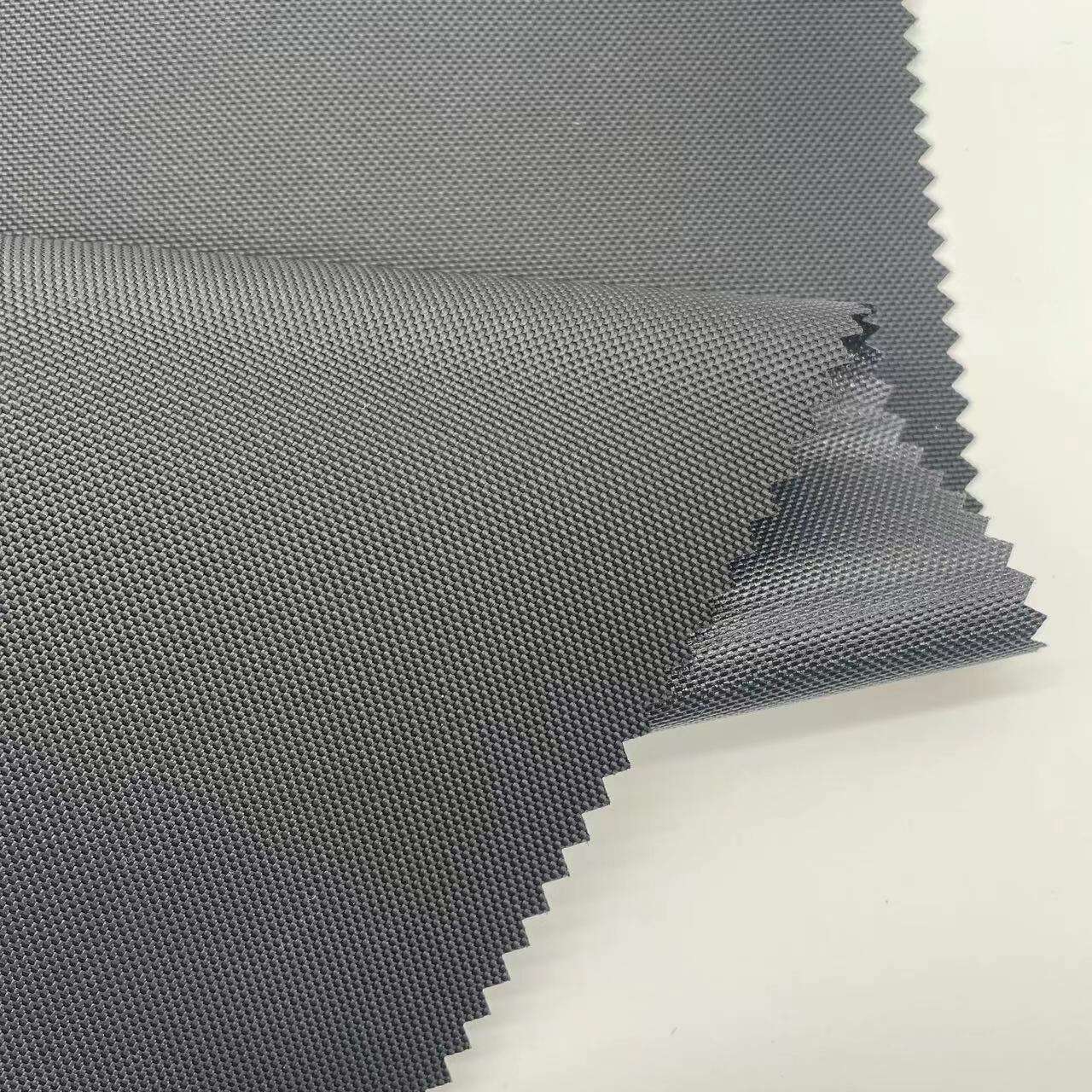

- Related products

- Inquiry

Parameter

210D Nylon 3MM Rip-stop Cordura® with 2-Pass PU Coating & Eco DWR

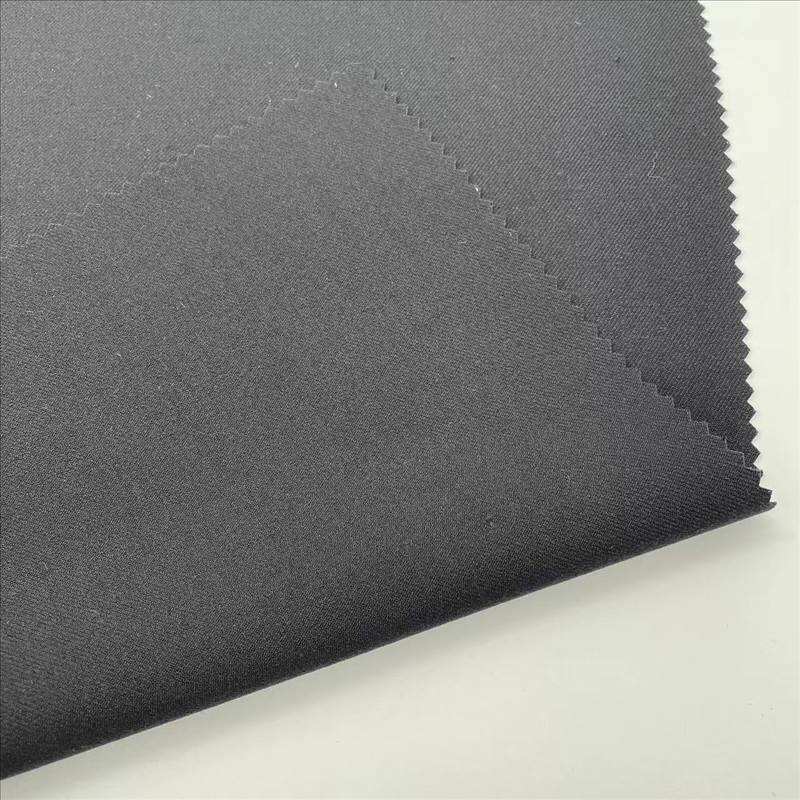

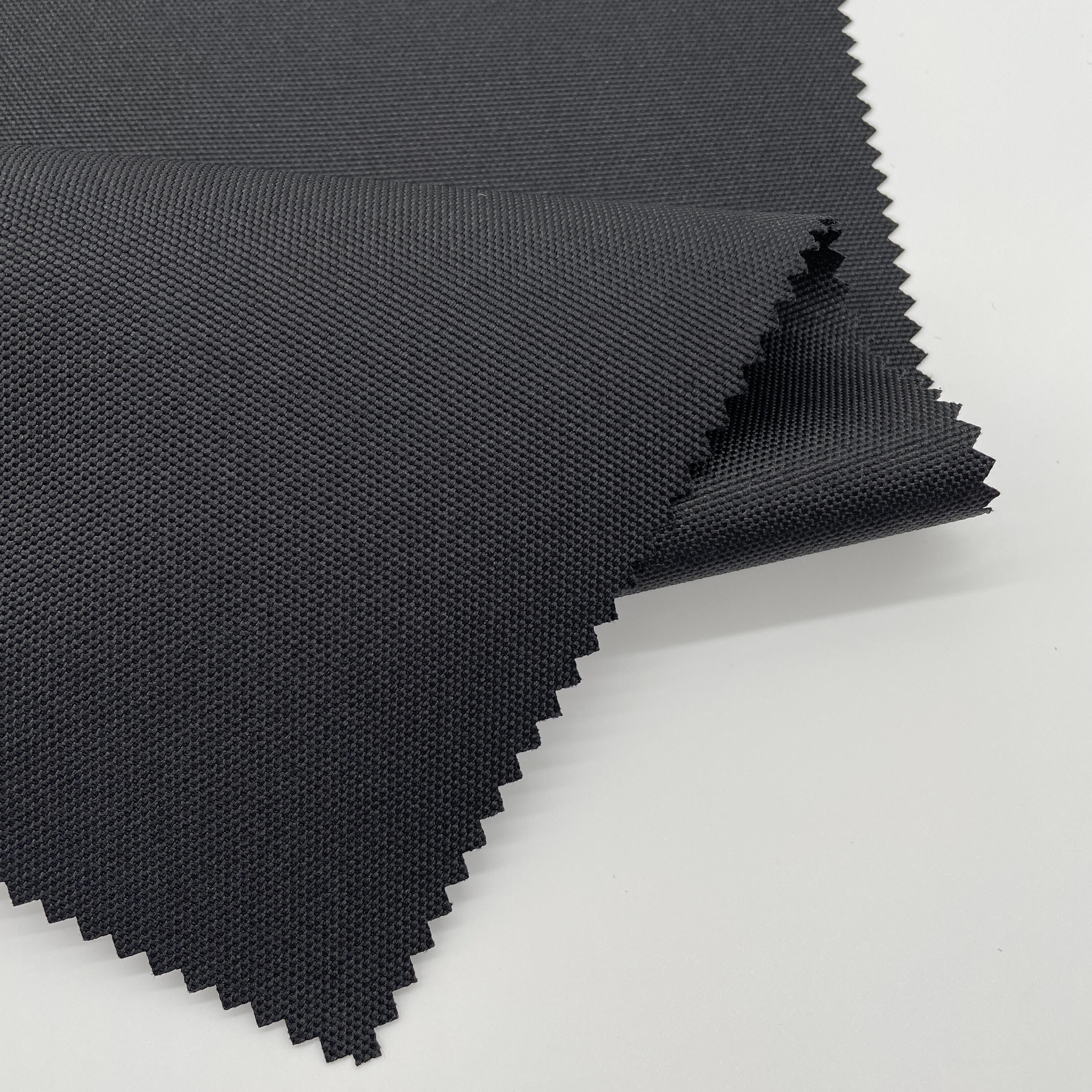

Engineered for applications where minimizing weight without sacrificing protection is paramount, this technical fabric is a masterclass in intelligent design. At its heart lies a resilient 210D nylon 3MM rip-stop cordura construction. The signature grid of thicker threads woven at precise intervals creates a robust matrix that effectively confines punctures and stops tears from propagating, significantly enhancing the material's longevity under stress. This foundational architecture provides an optimal balance of lightweight flexibility and inherent durability, making it an superior choice for demanding yet weight-conscious gear.

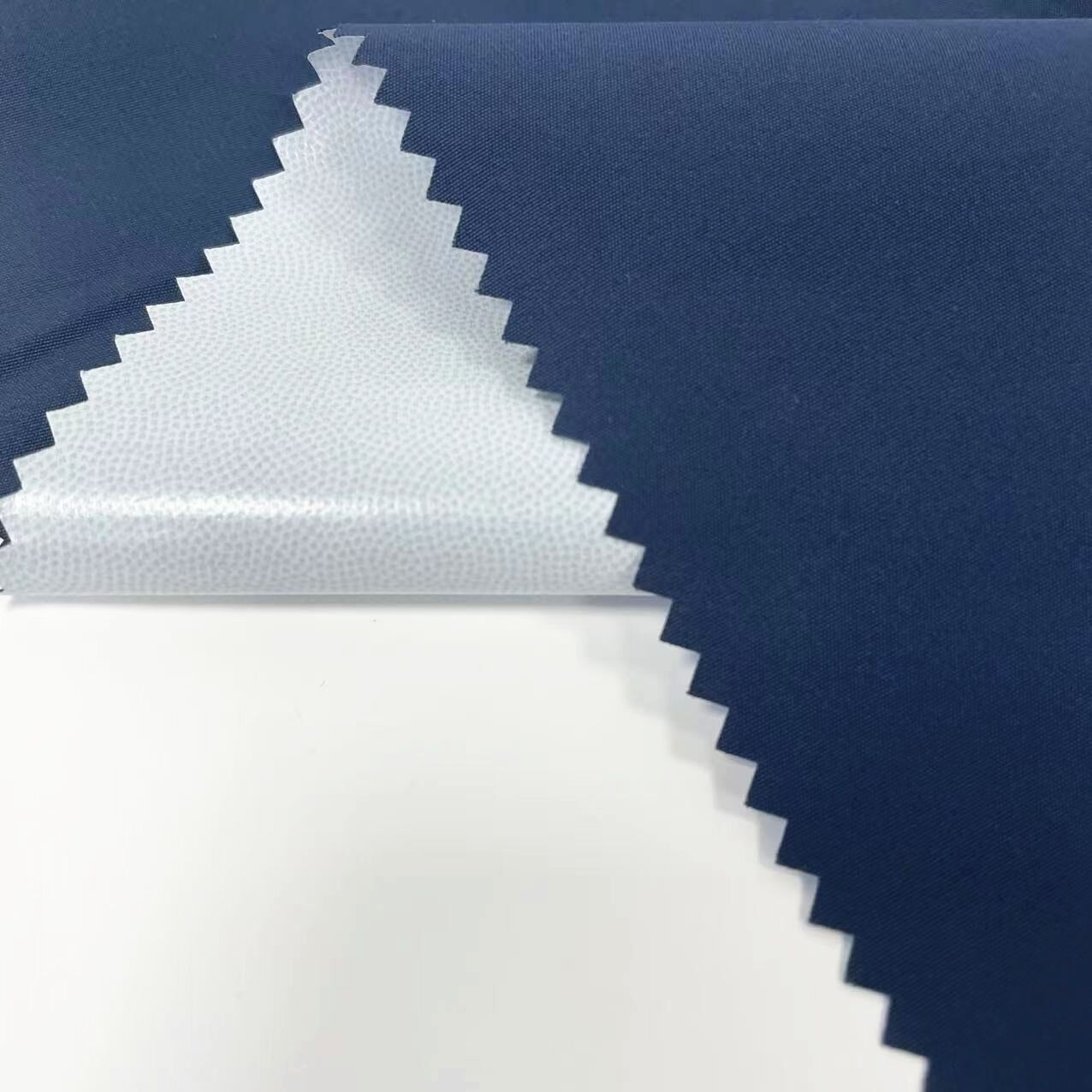

The high-performance nature of this fabric is unlocked through a meticulous two-stage enhancement process. A 2-pass polyurethane (PU) coating is applied to the reverse side, creating a formidable barrier against the elements. The first pass lays down a consistent foundation layer, which is then perfected and sealed by the second application. This method ensures a completely continuous waterproof membrane, eliminating pinholes and delivering a high hydrostatic head rating for assured dryness in wet conditions, all while maintaining a supple drape and reduced noise.

Completing this trifecta of protection is an advanced Environmental Durable Water Repellent (Eco DWR) finish applied to the face fabric. This treatment empowers the exterior to actively shed water, causing it to bead up and roll away instantly, preventing saturation that can add weight and compromise comfort. Formulated for a reduced environmental footprint, this Eco DWR retains its high efficacy through numerous washes and exposure to the elements. The combination of the intelligent 210D nylon 3MM rip-stop cordura grid, the impermeable dual PU coating, and the top-tier Eco DWR results in a highly reliable, lightweight fabric perfect for ultralight backpacking packs, technical shell garments, protective gear cases, and high-end tactical equipment, offering unparalleled defense against abrasion, moisture, and wear.

2. Service Process

Our collaborative partnership model ensures your vision is perfectly translated into reality:

• Discovery & Technical Dialogue: We initiate projects with an in-depth consultation to grasp your product's functional demands, design aesthetics, and target market.

• Customized Solution Development: Leveraging our expertise, we present a tailored material proposal, including samples of our 210D nylon 3MM rip-stop cordura and other options, alongside a transparent quotation.

• Sample Fabrication & Validation: We produce a development sample for your rigorous in-house testing, ensuring it meets all performance and quality benchmarks before full production.

• Precision Manufacturing & Transparency: Once approved, we move to manufacturing with real-time production tracking available, keeping you informed at every stage.

• Certified Delivery & After-Sales: Every meter of fabric undergoes final inspection and is shipped with necessary documentation, followed by dedicated account management for future needs.

3. Technical Standards & Quality Control Process

Our quality assurance is rooted in verifiable data and strict process control. We comply with a range of international standards, including ISO 811 for waterproofing and ASTM D751 for coating adhesion. Our in-house lab continuously tests for:

• Hydrostatic Head Resistance: Ensuring the 2-pass PU coating meets specified waterproof levels.

• Abrasion Cycles (Martindale): Quantifying the long-term durability of the fabric surface and coatings.

• Tear Strength (ASTM D5587): Confirming the enhanced durability provided by the rip-stop grid.

• DWR Efficacy (Spray Rating, AATCC 22): Objectively measuring the water-repellent performance of the Eco treatment.

• Our multi-stage QC protocol involves raw material certification, inline monitoring during weaving and coating for consistency, and a 100% final inspection for visual flaws, coating uniformity, and correct width.

4. Content Depth & Trust Building

We establish confidence through demonstrable competence and open communication. Beyond specifications, we provide application guides and technical white papers that help you design better products. Our long-standing partnerships with globally recognized brands are a testament to our commitment to reliability and excellence. We actively share our innovations in sustainable practices, such as our Eco DWR, proving our dedication to progressive manufacturing. You are engaging with a knowledgeable partner invested in the success of your final product.

5. Why Choose Us?

• Specialization in Technical Fabrics: Our focus is exclusively on high-performance materials, ensuring you benefit from deep, specialized expertise.

• Absolute Quality Consistency: Our rigorous, data-driven QC system guarantees you receive material that performs identically batch after batch.

• Unmatched Flexibility: We champion innovation by offering extensive OEM/ODM services and accommodating small-batch production runs from 500 meters, empowering brands of all sizes.

• Solutions-Oriented Partnership: We provide actionable technical support, helping you solve complex design challenges and optimize material selection.

• Forward-Thinking Manufacturing: Our investment in eco-friendly technologies like PFAS-free DWR ensures your products are aligned with modern environmental standards and market expectations.

6. OEM/ODM & Customization Support

We excel at bringing unique product concepts to life through our comprehensive OEM/ODM services. Our flexibility allows for extensive customization, including custom dye colors to match any palette, specialized coating formulations for specific hand feels or performance attributes, and even adjustments to the rip-stop pattern geometry. Understanding the need for agility in product development, we support innovative projects with a low minimum order quantity (MOQ of 500 meters), significantly reducing the barrier to entry for creating exclusive, high-performance products and enabling efficient market testing.

Applications:

210D Nylon is used in a variety of heavy-duty applications such as outdoor gear, pet accessories, and military/tactical gear.

Some common uses for this fabric include: Pet beds, luggage, bags, backpacks, tactical gear, horse blankets, wallets, gun cases, insulated food service carriers, footwear, and dog beds.

Specifications:

| Yarn: | 210D*210D | ISO 7211/5 |

| Composition: | 100%Nylon | ASTM D629 |

| Weave: | 3MM rip-stop | Visual |

| Density(in): | W68*F53 | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.25MM | ASTM D 1777 |

| Width: | 58'' | ASTM D 3774 |

| Weight: | 4.42 oz/sq yd | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:75N, F: 70N | ISO 13937-3 |

| Tensile strength 1'': | W:900N, F:800N | ISO 13934-1 Strip method |

| Abrasion Resistance: | Over 1000cycles | ASTM D3884-09 |

Competitive Advantage:

Taiwan Weaving Quality

Factory direct sell price

High tensile

Super durability

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ