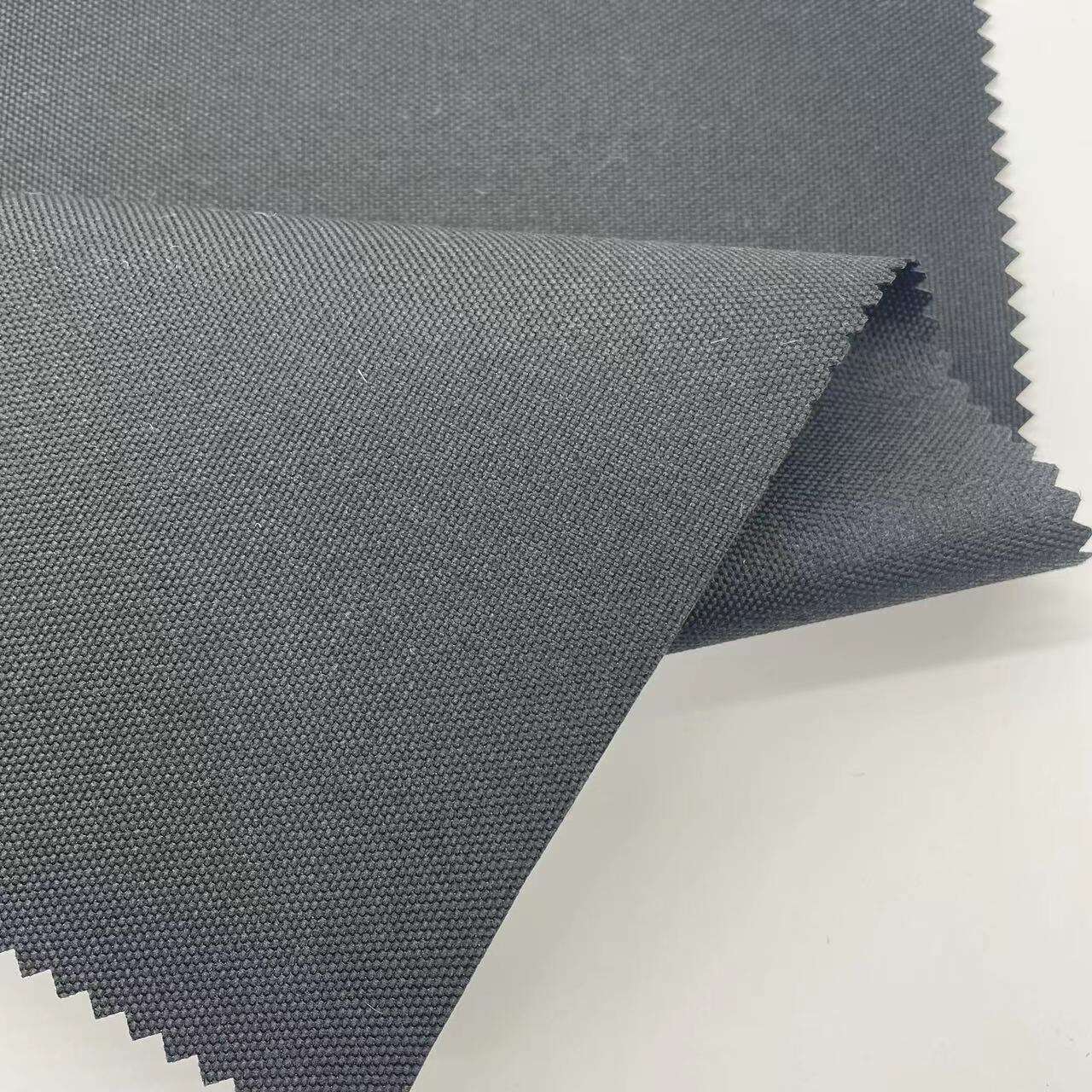

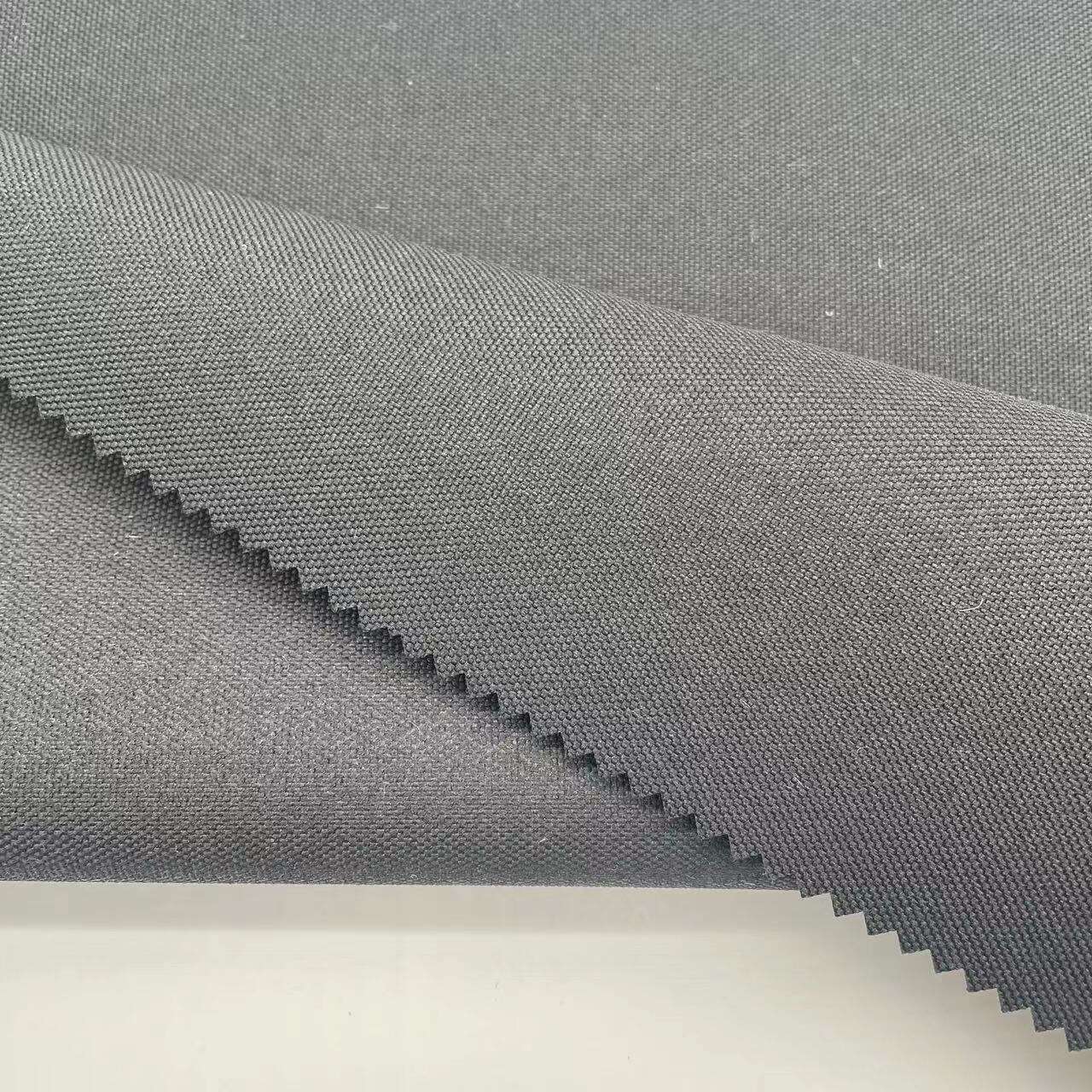

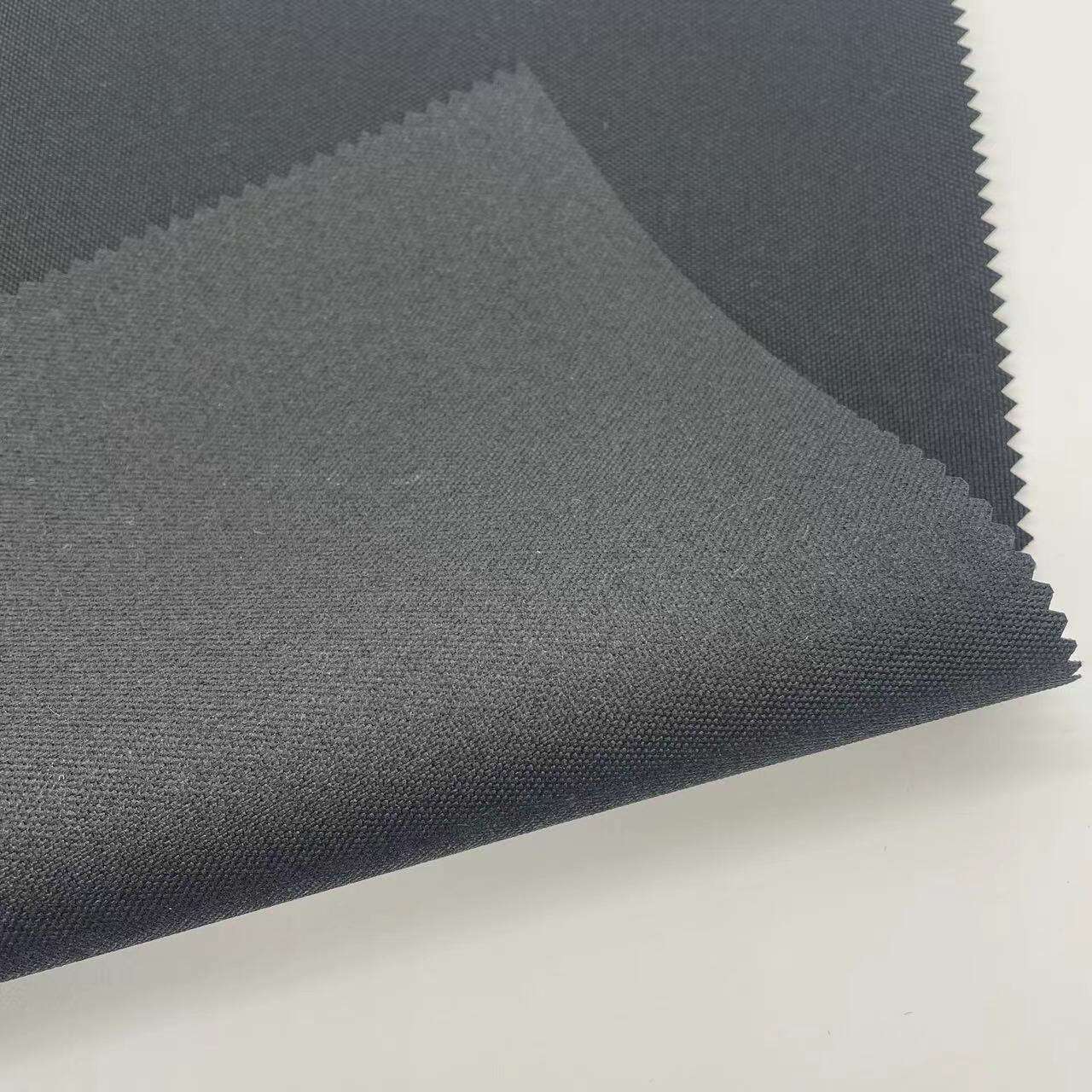

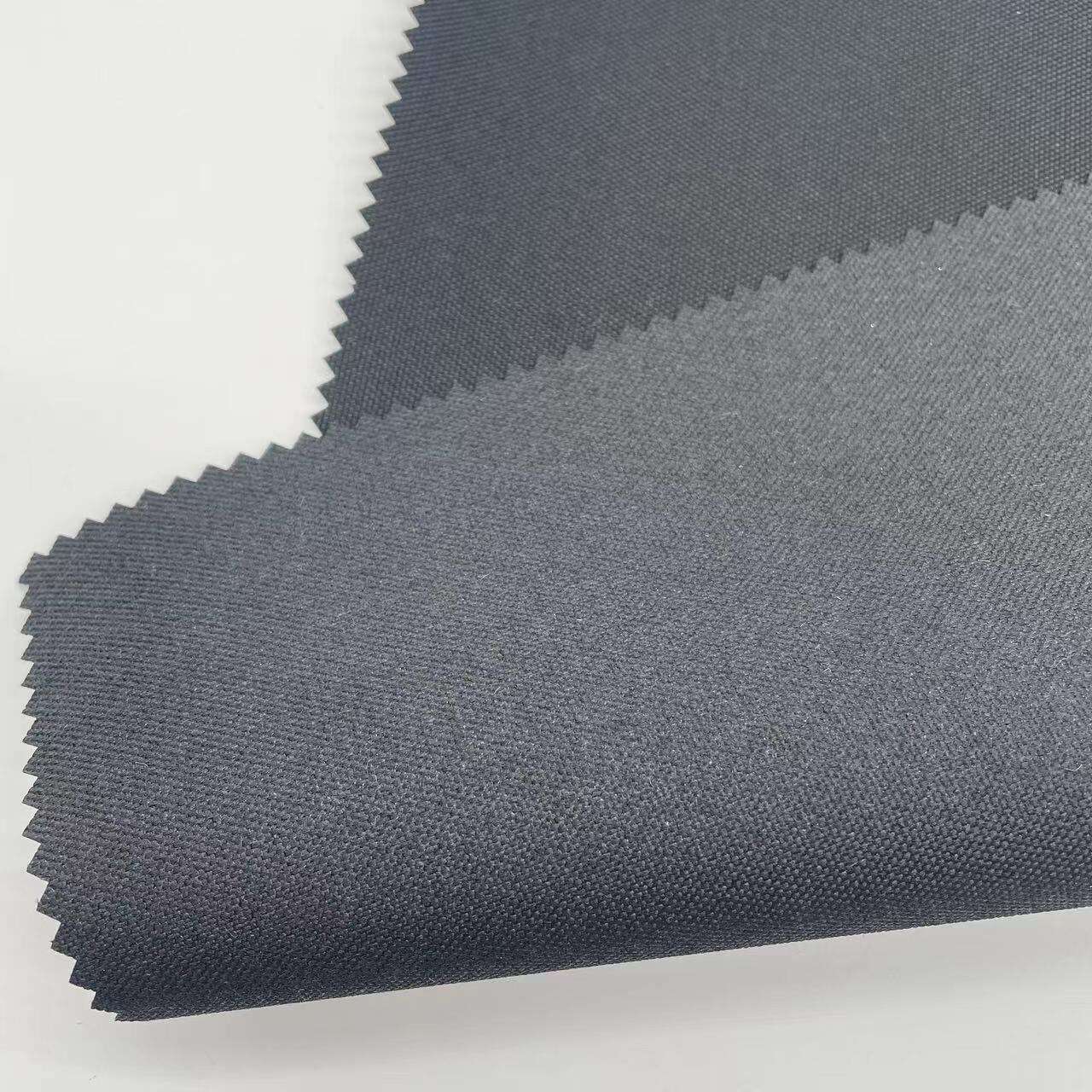

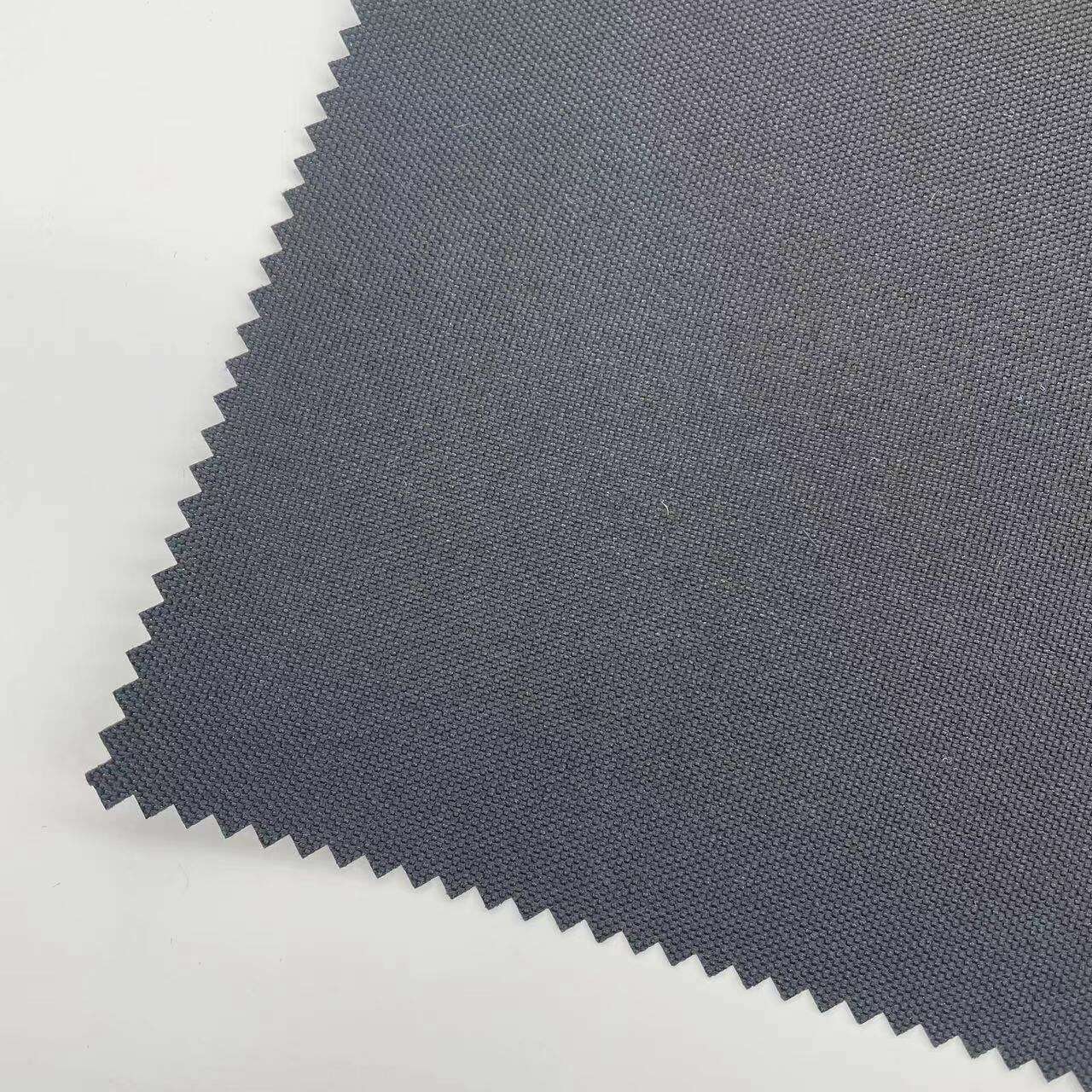

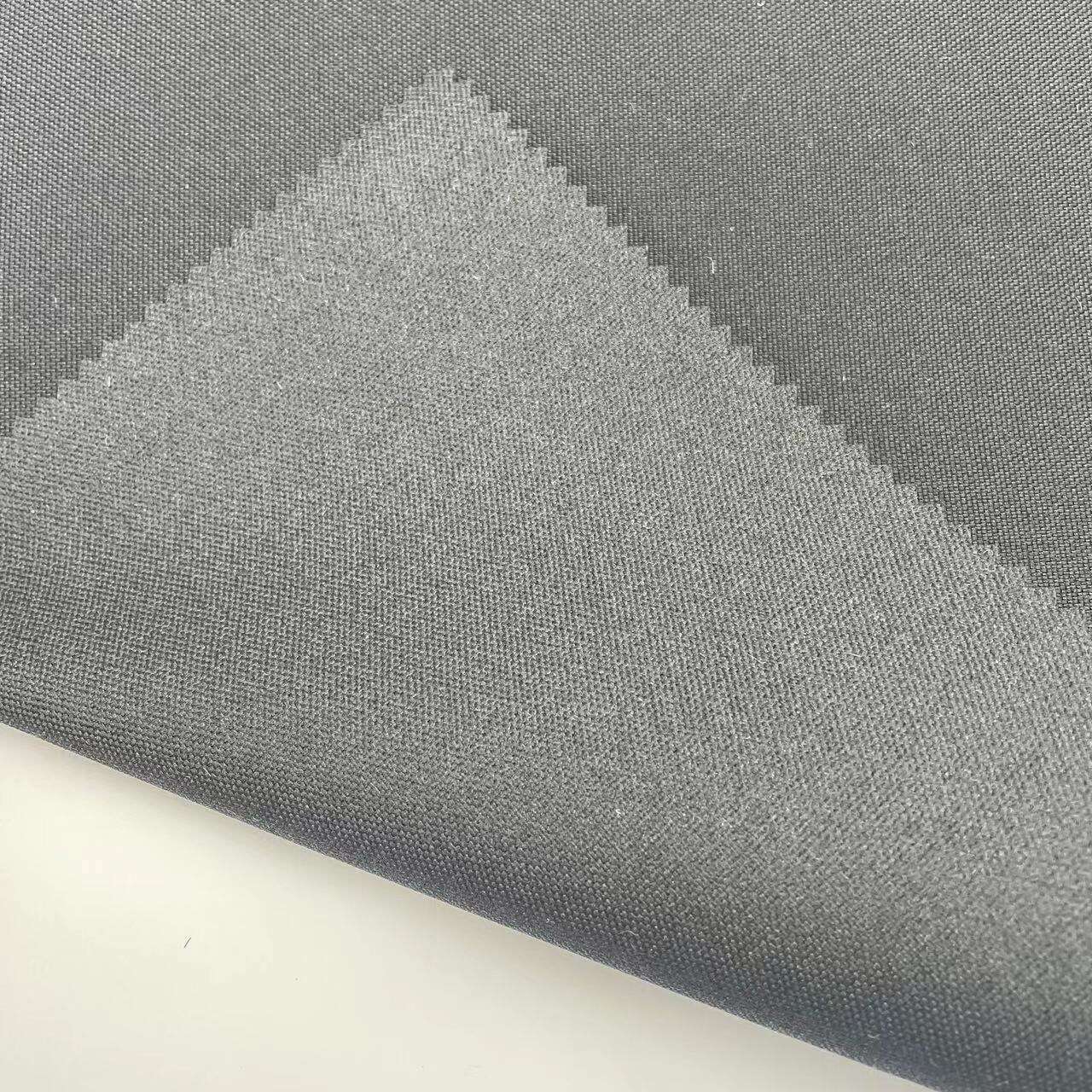

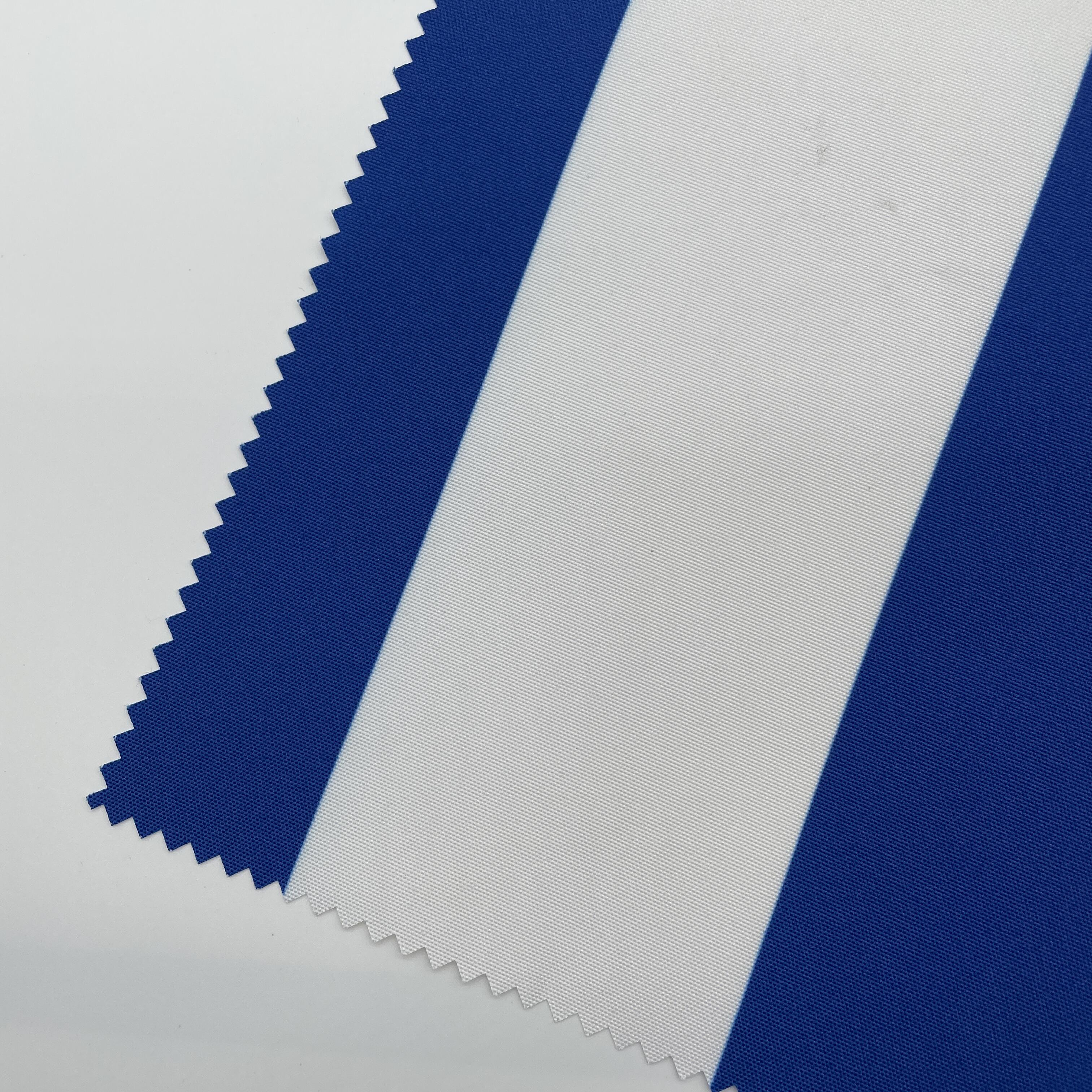

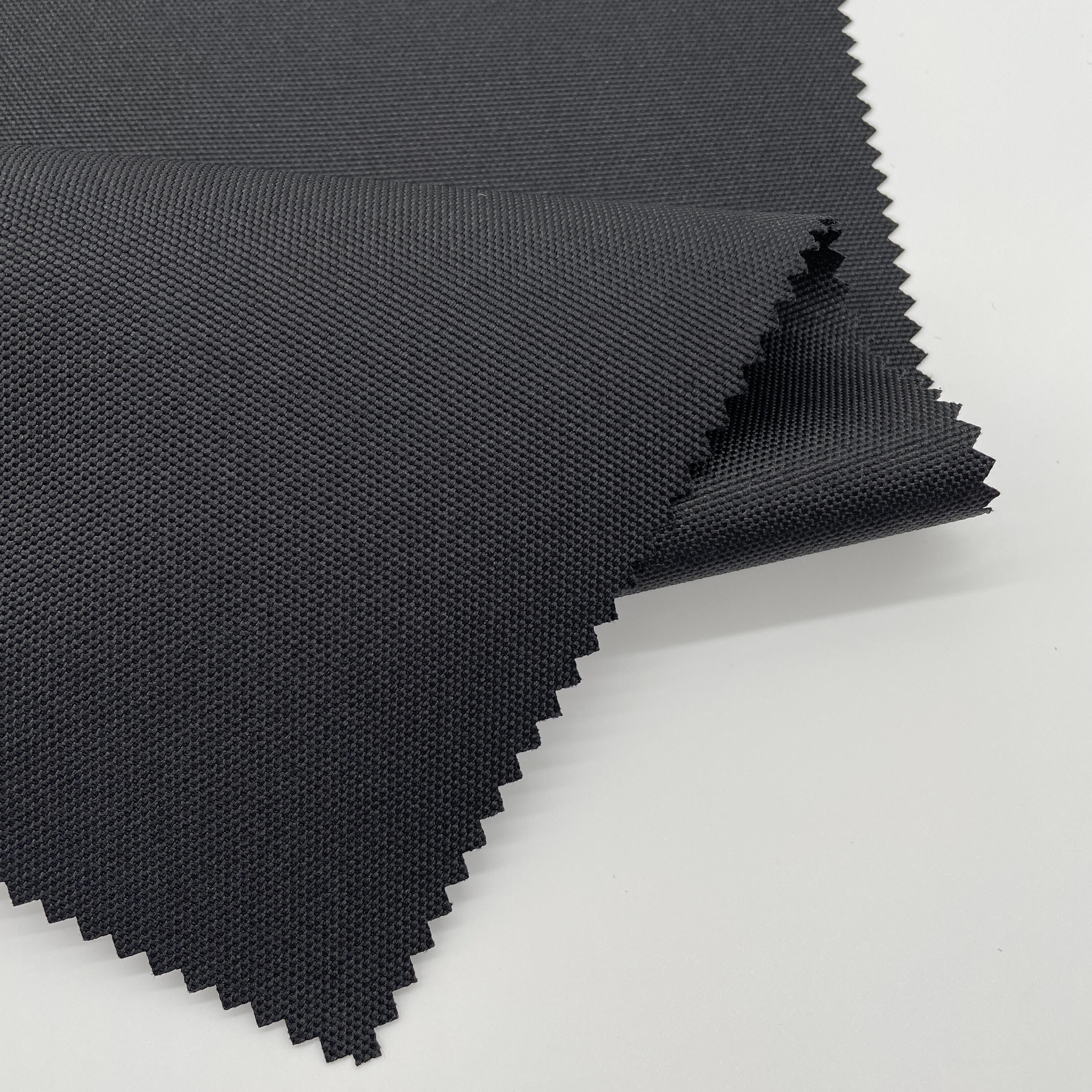

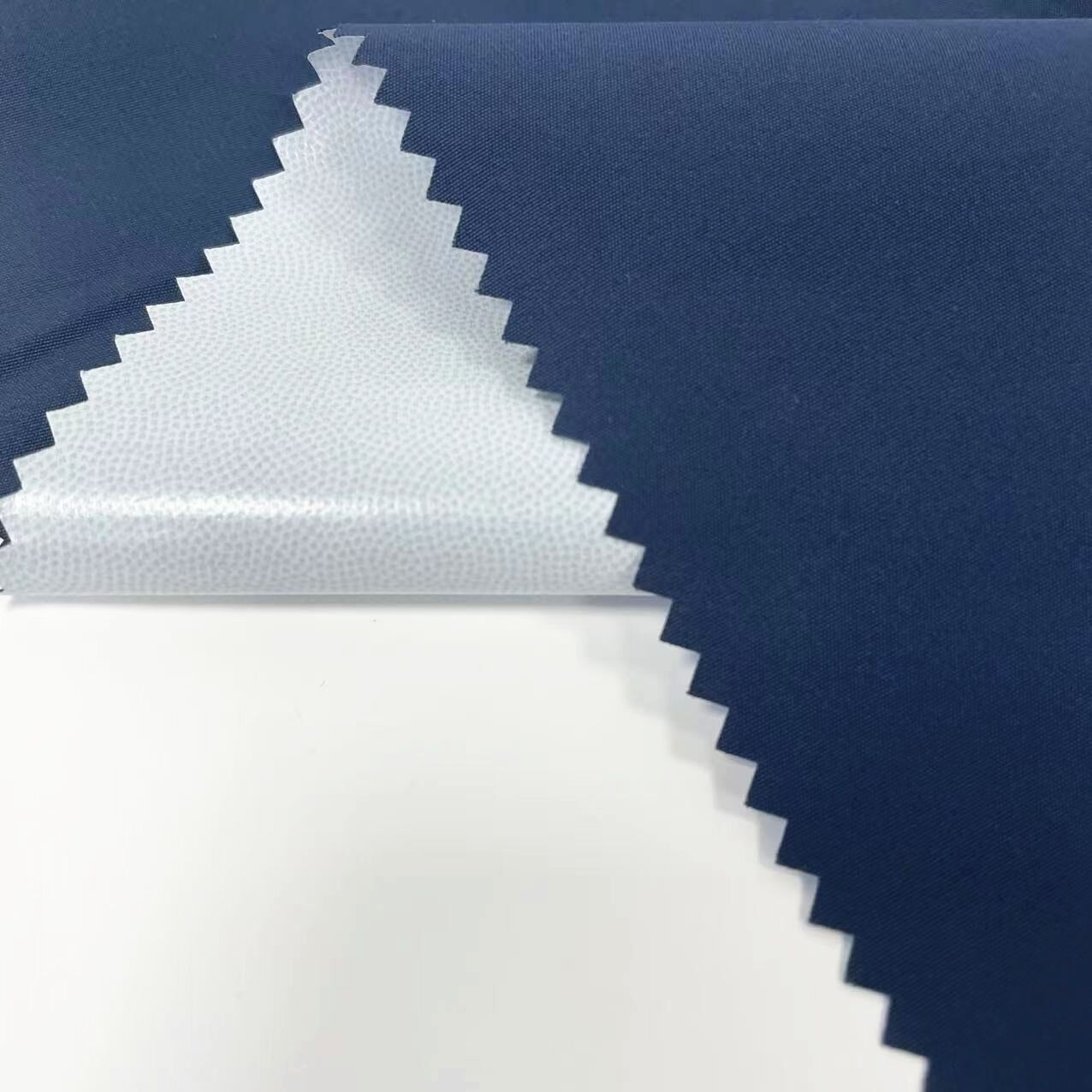

600D PU coated Polyester oxford fabric with durable water repellent

| Content: | Polyester |

| Coating: | PU(Polyurethane) |

| Country of origin: | China |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

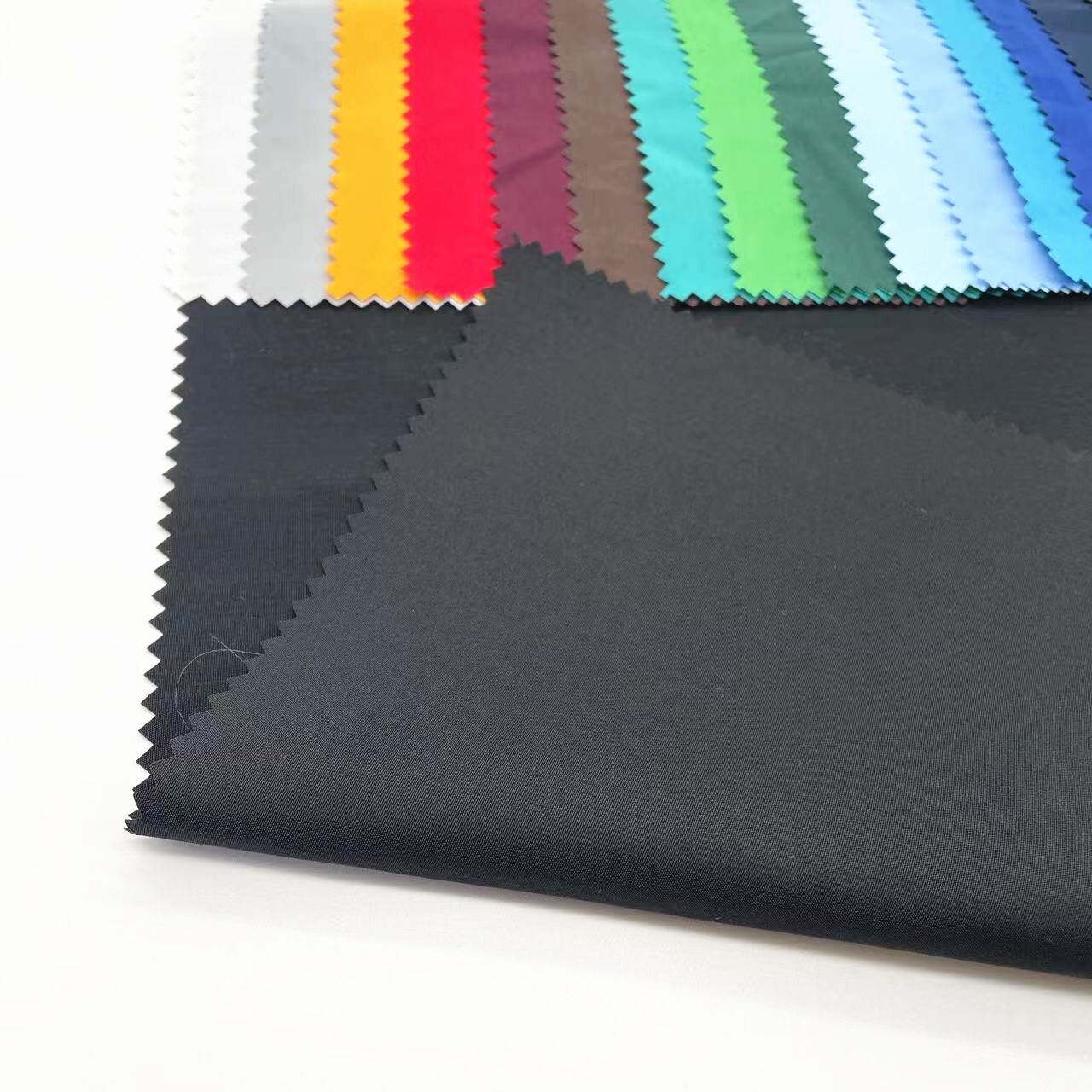

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

- Process flow

- Related products

- Inquiry

Parameter

600D polyester oxford fabric is made up of polyester draw texturing yarn(DTY) and it is the most common oxford. It has several common density like 64T, 72T, 74T, 78T, etc. Higher density means the higher weight and higher tensile strength. It can be coated with PU, PVC, TPE or TPU to meet different needs.

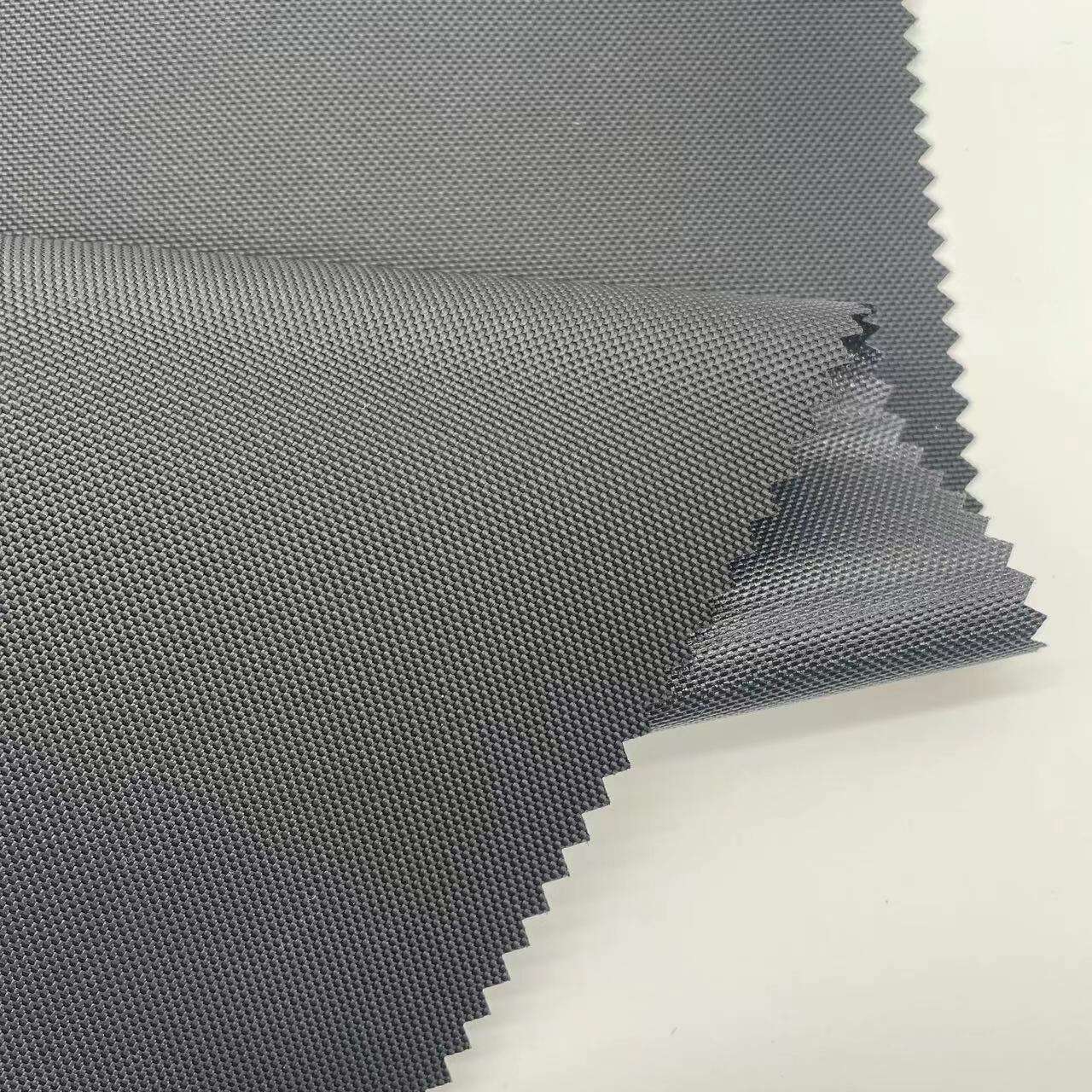

600D Polyester is known for being durable yet more affordable or budget friendly as opposed to Nylon. This fabric is tough and versatile making it a popular fabric choice of manufacturers.

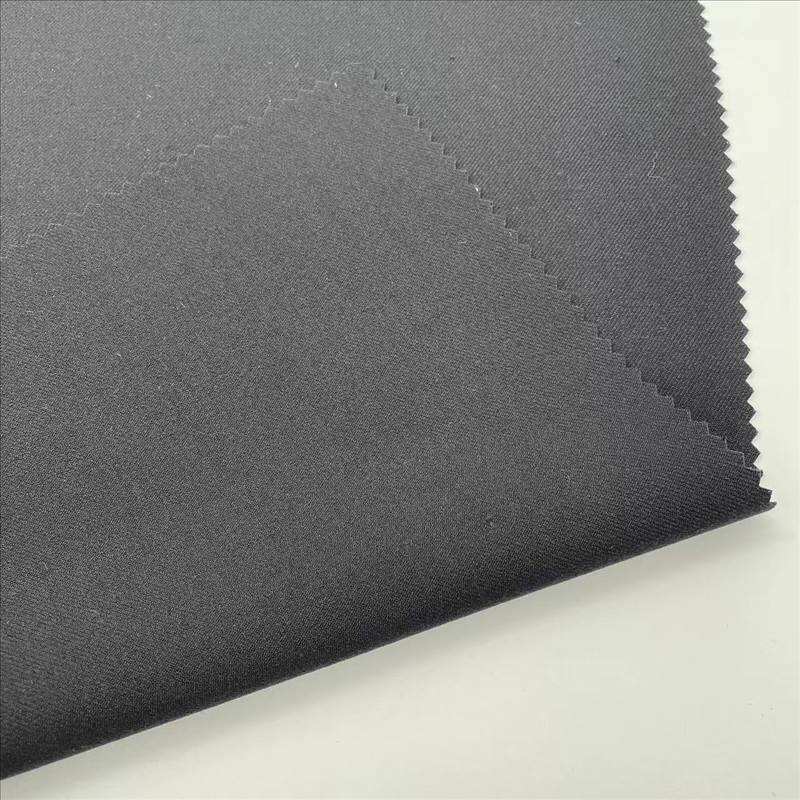

Engineered for superior performance and environmental adaptability, our PU coated 600D polyester oxford fabric represents a significant advancement in technical textiles for protective applications. This high-performance material combines the exceptional durability of 600 denier polyester with an advanced polyurethane coating system, creating a robust yet flexible solution for applications requiring reliable weather protection and long-term service life. Unlike traditional coatings, the PU formulation offers enhanced flexibility and temperature resistance, making it ideal for outdoor equipment, protective covers, and tactical gear that must perform in varying climatic conditions.

The exceptional quality of this PU coated 600D polyester oxford fabric begins with its high-density oxford weave construction, providing excellent resistance to abrasion, tearing, and puncturing. The polyurethane coating is applied using precision-controlled coating technology, ensuring uniform coverage and consistent performance across the entire fabric surface. This advanced coating system is further enhanced with a durable water repellent (DWR) treatment that creates a protective barrier against moisture penetration while maintaining breathability. The result is a versatile PU coated 600D polyester oxford fabric that offers outstanding waterproof performance without compromising flexibility or hand feel, making it suitable for applications where both protection and mobility are essential.

Rigorous Quality Assurance Process:

We maintain uncompromising quality standards throughout our manufacturing process. Our PU coated 600D polyester oxford fabric undergoes comprehensive testing for waterproof performance (ISO 811 hydrostatic pressure test), coating adhesion (ASTM D751), low-temperature flexibility (ASTM D2136), and UV resistance (AATCC TM16). Each production batch is accompanied by detailed test reports and material certifications, ensuring full compliance with international standards and providing complete transparency for your quality assurance requirements. Our quality control team conducts regular audits and inspections to guarantee consistent performance across all production runs.

Why Choose Our Solution:

Technical Collaboration: We provide end-to-end support from material selection to production guidance, including technical consultation on welding parameters and fabrication techniques.

Proven Performance: Trusted by manufacturers in outdoor, automotive, and protective equipment industries for consistent quality and reliability.

Flexible Manufacturing: With a low MOQ of 1000 meters, we support both prototype development and small-batch production requirements.

Quality Commitment: Full material traceability and certification ensure consistent performance and compliance.

Technical Expertise: Our team brings decades of experience in coated fabrics to provide solutions for your specific application needs.

Choose our PU coated 600D polyester oxford fabric for applications where superior weather protection and durability are required. This fabric offers an optimal balance of waterproof performance, flexibility, and long-term reliability for demanding outdoor and industrial applications. Contact us today to discuss your specific requirements and request material samples for testing and evaluation. Our technical team is ready to provide expert guidance and support for your project needs.

Applications:

600D is most used for backpacks, school and equipment bags, yet customers also utilize it to produce boat covers and awnings due to its water and mildew resistant qualities.

600D Polyester is commonly used to create bags and outdoor gear.

Some common uses for this fabric include: backpacks, school and equipment bags, luggage, computer cases, boat covers, and awnings.

Specifications:

| Yarn: | 600D*600D | ISO 7211/5 |

| Composition: | 100%Polyester | ASTM D629 |

| Weave: | plain | Visual |

| Density(in): | W48*F24 | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.45MM | ASTM D 1777 |

| Width: | 60'' | ASTM D 3774 |

| Weight: | 7.2oz/sq yd | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | W:47LBF, F: 32LBF | ASTM D1424 |

| Tensile strength 1'': | W:253LBF, F:172LBF | ASTM D5034-21 Grab test |

| Hydrostatic Pressure: | 500MM | AATCC TM127 |

Competitive Advantage:

High Quality

Factory direct sell price

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ