A ripstop nylon egyfajta merev, szintetikus szövet, amely rendkívül ellenálló a szakadásokkal és hasításokkal szemben. A SULY Textile kiváló minőségű és teljesítményű ripstop nylon szövetek kínálatára specializálódott. Ismerje meg a ripstop használatának előnyeit Nylon szövet a termékeiben, és azt, milyen sokoldalú ez az anyag különböző iparágakban.

A ripstop nylon anyag híres erősségéről és szakadásállóságáról. Ez kiváló választást jelent bármihez, amelyhez tartós, hosszú élettartamú anyag szükséges. Akár túrafelszerelésben, akár kabátokban és nadrágokban használják, a ripstop nylon anyag megbízható teljesítményt nyújtó megoldás, amely nem kopik el könnyen a durva használat során. Ráadásul a ripstop nylon szövet könnyű súlyú, így kényelmes viselni és egyszerű hordozni. A legjobb minőségű ripstop nylon anyag. Az állóság és a könnyűség tulajdonságai miatt a ripstop nylon anyag nagy keresletnek örvend az olyan gyártók körében, akik magas minőségű, hosszú élettartamú termékeket szeretnének előállítani.

A ripstop nylon anyag rendkívül sokoldalú, és számos iparágban felhasználható. A túraiparban a ripstop nylon kiváló választás sátrakhoz és függőágyakhoz, mivel erős és vízálló tulajdonságú. A divatiparban az aktív viselet és a felsőruházat gyakran használja a magas szilárdság-súly arány és a viszonylag alacsony költség miatt. Ezen felül a ripstop nyont használják az autóiparban autóburkolatokhoz és járművédelmi ruházathoz, valamint az orvostechnikai iparban formákhoz és berendezések fedeleihez. Mindenféle ripstop nylon stretchy bármely iparágban történő felhasználása tanúsítja sokoldalúságát és vonzerejét – nyilvánvalóan vonzó lehetőség olyan gyártók számára, akik kopásálló, ugyanakkor sokoldalú anyagra vágynak.

A ripstop nylon anyag a legerősebb, ugyanakkor könnyű anyag, amely kiválóan alkalmas vízálló kabátok és ruházat készítésére. A speciális kötés fokozza az anyag szilárdságát, és megakadályozza, hogy kis szakadások vagy repedések továbbterjedjenek, így a ripstop nylon tartós és megbízható. Ellentétben a piacon kapható hagyományos nylon anyagok többségével, a ripstop nylon bármilyen alkalmazásban használható a súly csökkentése és a tartósság növelése érdekében. Az egyik másik fő oka annak, hogy miért részesítik előnyben túrázók és természetkedvelők, az alacsony súlya, amely elkerüli, hogy túlságosan nagy méretű legyen a túratáska. A ripstop nylon rendelkezik figyelemre méltó szilárdság-súly aránnyal, és gyakran vízálló vagy vízhatlan tulajdonsággal is rendelkezik – ideális minőségek minden olyan személy számára, aki kinti kalandok során megbízható felszerelésre szorul.

Mindezen előnyök mellett azonban számos gyakori tévhit is létezik a ripstop nylonnal kapcsolatban, amelyek zavart okozhatnak. Az egyik leggyakoribb félreértés az, hogy a ripstop nylon nem lélegzik. Igazából helyes az állítás, hogy a ripstop nylon nem lélegzik olyan jól, mint néhány természetes szál (nos, valószínűleg a pamut), de a modern anyagtechnológiák segítségével ma már lényegesen jobban lélegzik, mint valaha. Egy másik tévhit, hogy a ripstop nylon nem környezetbarát. Számos cég, köztük a SULY Textile is, azt ígéri, hogy környezetkímélő és fenntartható módon gyártja a ripstop nyont, újrahasznosított anyagok felhasználásával, és a gyártás során minimális, vagy egyáltalán nincs hulladéktermelés. Miután eloszlatjuk ezeket a tévhiteket, világossá válik, miért olyan sokoldalú és környezetbarát anyag a ripstop nylon az outdoor felszerelések gyártásához.

A cég fő termékei a Softshell anyag, Hard shell anyag, RPET anyag, Ripstop nylon anyag, táska anyag, tollbarnákhoz való anyag, Aramid anyag, Cordura anyag, amely tűzgátló stb. Cégünk OEM szolgáltatást is kínál, amely lehetővé teszi számunkra, hogy a követelményeknek megfelelően szőjük az anyagot, például darabok festése és gyűrött festése. Kínálhatunk antistatikus bevonatokat, TPU/TPE átlátszó, TPU tejszerű/átlátszó tűzgátló, nagy lélegzőképességű, blackout, PA, ecsetelt, PVC laminálásokat, PU átvitel és még sok más.

A cég ISO9001, OEKO, SGS és egyéb tanúsításokkal rendelkezik. Emellett saját tesztelőközponttal is rendelkezünk a Ripstop nylon anyagok teljes körű vizsgálatára, továbbá egy helyi, tanúsított harmadik fél tesztelőközponttal is együttműködünk, amely gyors, pontos és hitelesített vizsgálati jelentéseket tud készíteni számunkra. Értékesítési személyzetünk gyorsan és pontosan válaszol az ügyfelek kéréseire. Van egy szállítási csapatunk is, amely megoldásokat kínál a szállítással kapcsolatos problémák esetén.

A Suly Textile egy szakmai textíliagyártó vállalat, amely 20 000 négyzetméternyi területet foglal el, és gyárt Ripstop nylon anyagot PU bevonatos vonalakon. Ezek a PU bevonatos vonalak az Egyesült Államokból származnak, és jobb minőségű bevonatot biztosítanak. Két PVC bevonatos vonalunk is van, amelyek különféle textíliákat állítanak elő kültéri kabátokhoz, táskákhoz, sátrakhoz, ipari felhasználásra stb. Technikusaink mindegyike több mint 10 éves tapasztalattal rendelkezik a textíliagyártás területén, és minőség-vezérelt szolgáltatásokat és megoldásokat tudnak nyújtani. Nylon textíliánk a leg erősebb termékünk, amelyet Tajvanról importálunk – a feldolgozatlan (greige) és a festett anyagot is –, majd saját gyártóüzemünkben fejezzük be a feldolgozást.

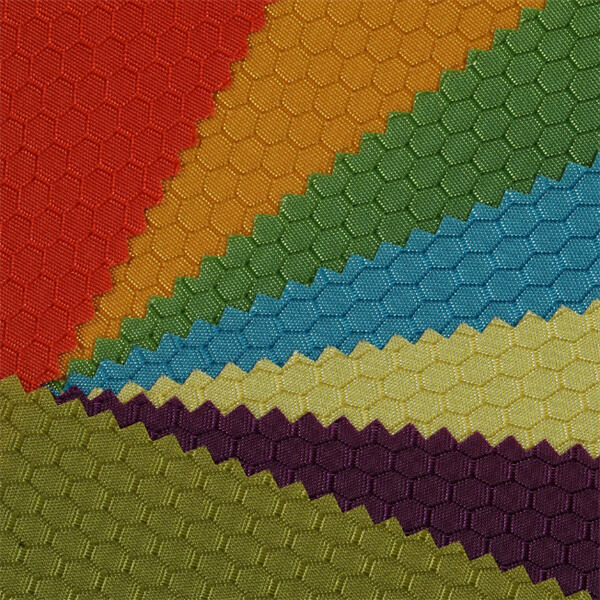

A Suly Textile széles választékú textíliákat kínál, amelyeket a ripstop nylon anyag követelményeinek megfelelően lehet testre szabni. A cég gyártással és forgalmazással foglalkozik mindenféle vegyi anyagból készült és kevert textíliák esetében, beleértve a festést, bevonatokat, ragasztást és laminálást is. Szakosodtunk funkcionális textíliákra, például erősen vízhatlan anyagokra és magas vízoszlopos textíliákra. Emellett antistatikus, UV-védett, nedvességet elnyelő, gyorsan száradó, lángálló, hőálló, nyomtatott és IFR (integritás-megőrző) textíliákat is kínálunk. Alacsony minimális rendelési mennyiséggel (MOQ) is elfogadunk nyomtatási megrendeléseket. Széles textíliaválasztékot kínálunk, és egyetlen forrásból történő teljes körű megoldást nyújtunk.