The World of Fabric Design Tactics Beneath the Surface

This course takes you for a creative ride exploring the amazing landscape of fabric design techniques! Not only is designing fabric so much FUN but it's a great way to really let your creative flag fly! There are unlimited techniques that you can explore to get your fabric design ideas down on paper or screen. Deeper Insights into Some Fascinating Approaches

Ex: A popular example is the traditional batik technique. It is an involved process of using wax and dye to lay intricate patterns onto fabric. More specific: wax is used to resist the dye, rendering beautiful patterns that tell a greater story with rich tradition behind it.

Another fun technique using a lot of color is tie-dye. All you need to do is fold, bind with rubber bands and dye the fabric in amazing patterns creating a whole collection of designs and colors. One thing is for damn sure, and that's the unpredictability of tie-dye - a quality which has long been to its detriment but also more recently coming around as all part of it undeniably joy-inducing nature.

How do you get started with creating your own custom printed fabrics?

For thousands of people who have always aspired to witness their own artistic visions take form on fabric, creating custom prints. What if you can print on fabric and get your favorite animal or geometric pattern? To do so, stencil your work. You can then choose to digitize it with a computer program or take the design and have it made into screens at a screen printing shop for example.

Dive into the world of screen printing, a method in which ink is pushed through an image on fabric to create detailed prints. You will require various tools to embark on this creative journey, including a mesh screen and an intricate stencil.

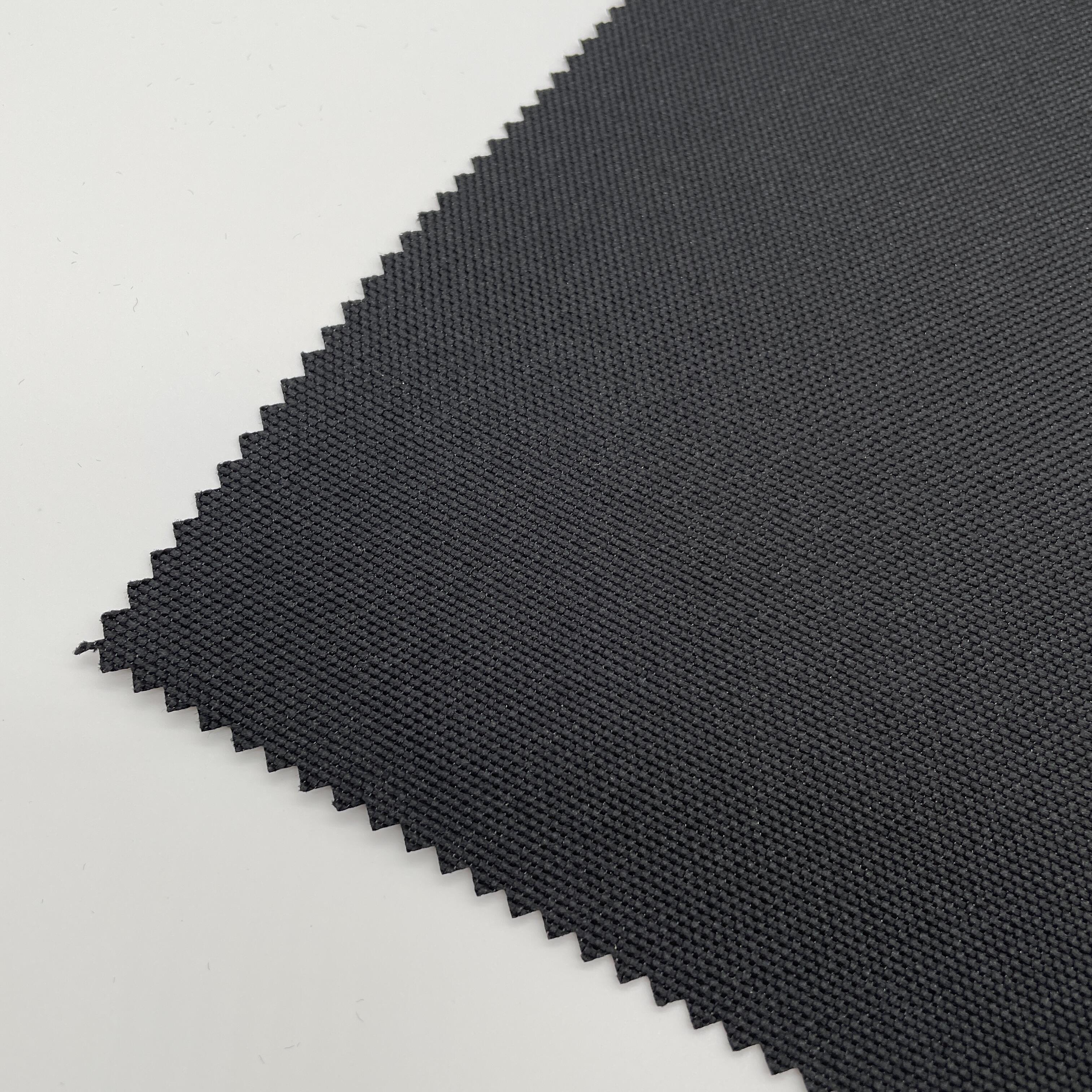

Place the screen over what you want to print on, like this fabric surface. Ink is placed onto the screen, and a squeegee pulls the ink through holes in stencil to print an image on top of your garment! Gently pick up the screen from your fabric, to unveil...your masterpiece!

Below, find a more detailed walk through for those you want to get into this process of printing by hand on fabric.

Use cotton or polyester fabric to avoid these problem with you ink because it is absorptive.

Create your stencil - whether hand-drawn or digitally, made in a computer program.

(Be sure that the screen is secure on both all sides and flat against the fabric.

The squeegee is used to forcibly apply ink onto the top of a screen and push it through the mesh openings.

Peel the screen away from your fabric gently and carefully to transfer a clean print.

By the time you finish pressing down all of your pieces, it is more than dry and will survive a wash or two) Once everything has been pressed firmly in place Remove the freezer paper, allow to set for one minute before removing from screen.

Screen printing may be difficult, but it can also demand new approaches to enhance your results. To help you trick out your screen printing activities, here are a few seasoned tips.

Pick the correct kind of ink depending on the fabric that you are going to use for an optimal outcome.

Let dry your stencil throughly before start printing so as to not get smudged.

Play around with the pressure you use to apply ink through the screen Draws also allow for unpredictable effects, promoting things like wash or exhausted shading.

All in all.. do Print on Fabric its fun, it gives you a unique way to express your creativeness and come up with what ever design that most fits for you. Whether you are creating a lively apron for your home cook or just need to add some decorations at the door, screenprint is an easy and low-cost way that shows creativity in every one of us. When you follow the steps outlined and learn some of these pro tips, you will be well on your way to becoming a master screen printer.

Suly Textile can provide various kinds of customized fabrics to meet the demands of customers. The company is involved in the manufacturing and selling of all kinds screen printing on fabric and blended fabric dyeing, coating bonding and laminating. We are specialized in functional fabrics like strong water repellent fabric and high water column fabric. We also offer anti-static, anti UV, moisture absorbing, quick drying, anti-heat, flame retardant printed IFR and printed. Additionally, we offer low MOQ printing for printing. We offer a range of fabrics and provide a single-stop solution.

Suly Textile is a screen printing on fabric fabric producer that covers an area of 20,000 square metres. Suly Textile has 4 lines of PU coating lines and these lines of PU coating were imported to offer a higher quality coating. Meanwhile we also have 2 lines of PVC coating lines that create outdoor clothing bags, tents and industrial use. Our technician all have over 10 years of experience in the field of textile production and are able to provide better quality controlled services and solutions. Our nylon fabric is our strong product that we import from Taiwan Greige and dye, and create finishing at our own facility.

The main product of the company is screen printing on fabric, Hard shell fabric, RPET fabric Fabric for workwear, Bag fabric Down jacket fabric Aramid fabric, Cordura Fabric that is flame retardant, etc. Our company also provides custom-made services, which allow us to weave to your specifications, including piece dyeing or crinkled dyeing. We can also supply TPU/TPE coatings, antistatic and anti-static TPU milky/clear, fire retardant, high breathable black-out, PA brush, PVC laminations, PU transfer and more.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our local certified screen printing on fabric testing center who can give us fast, exact and certified testing reports. We have our own expert sales staff and we are able to give customer very fast relying and address any customer concerns. We also have a shipping staff that can offer solutions for shipping if the customer is having difficulty with shipping.