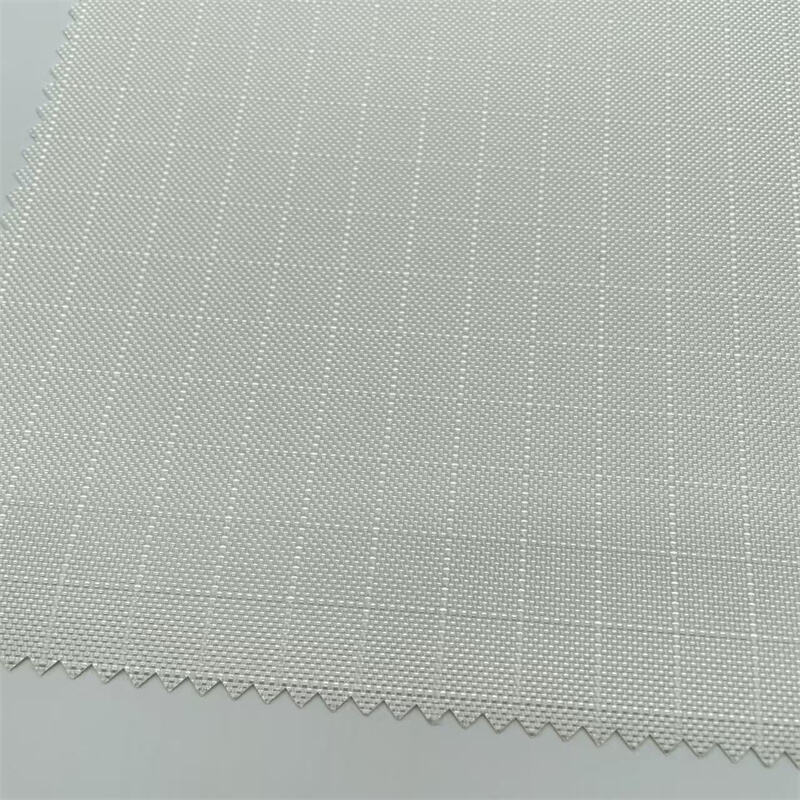

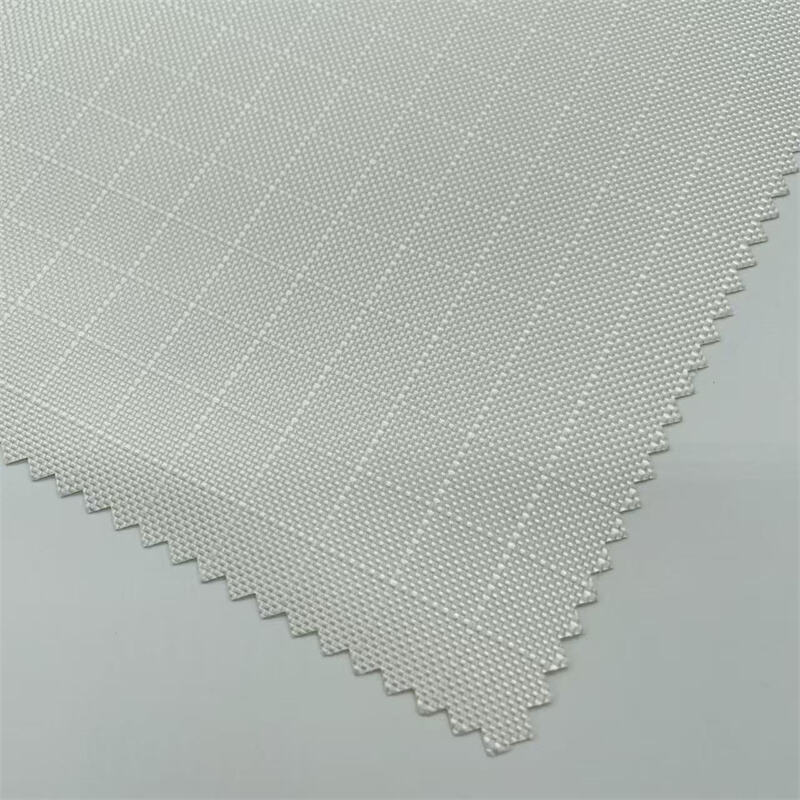

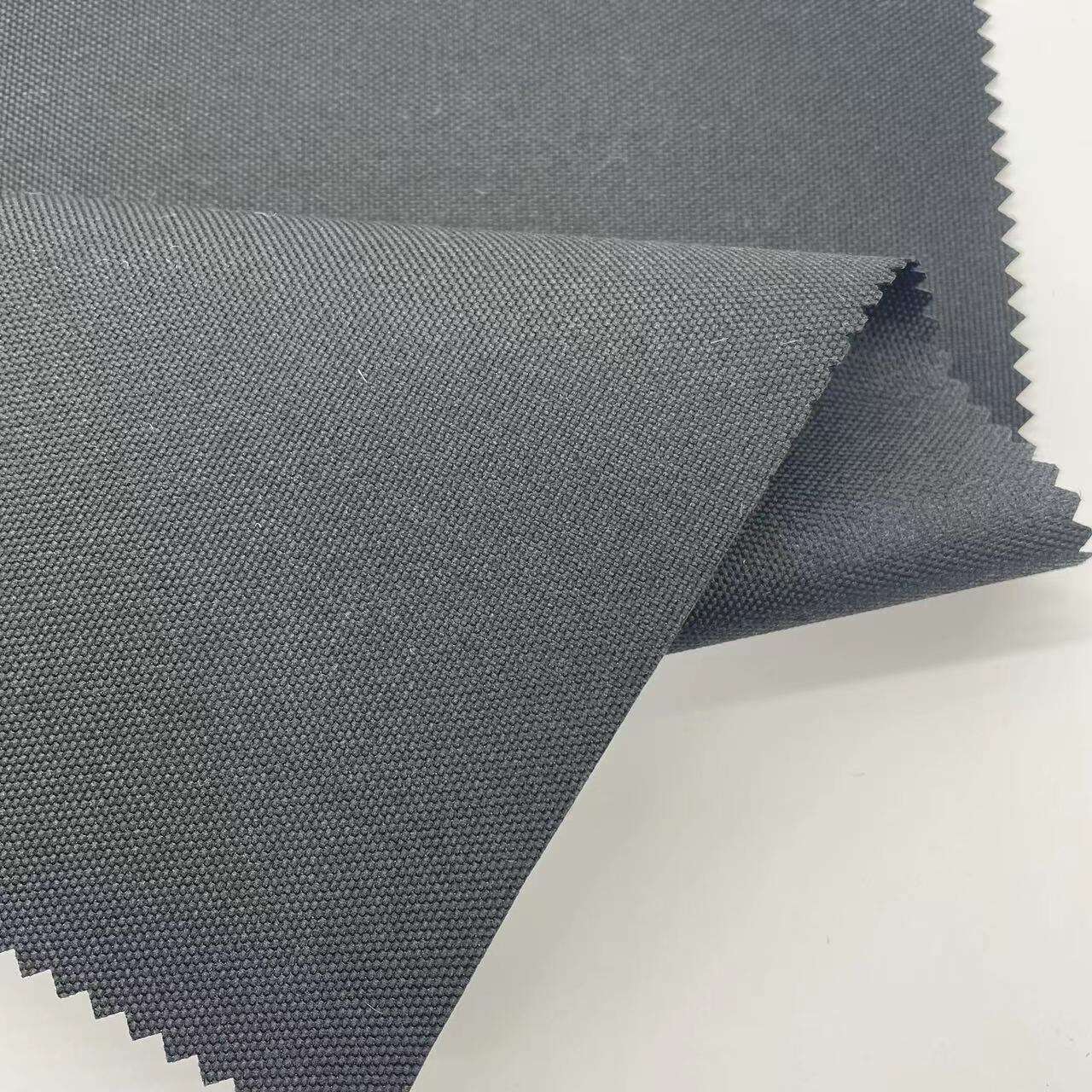

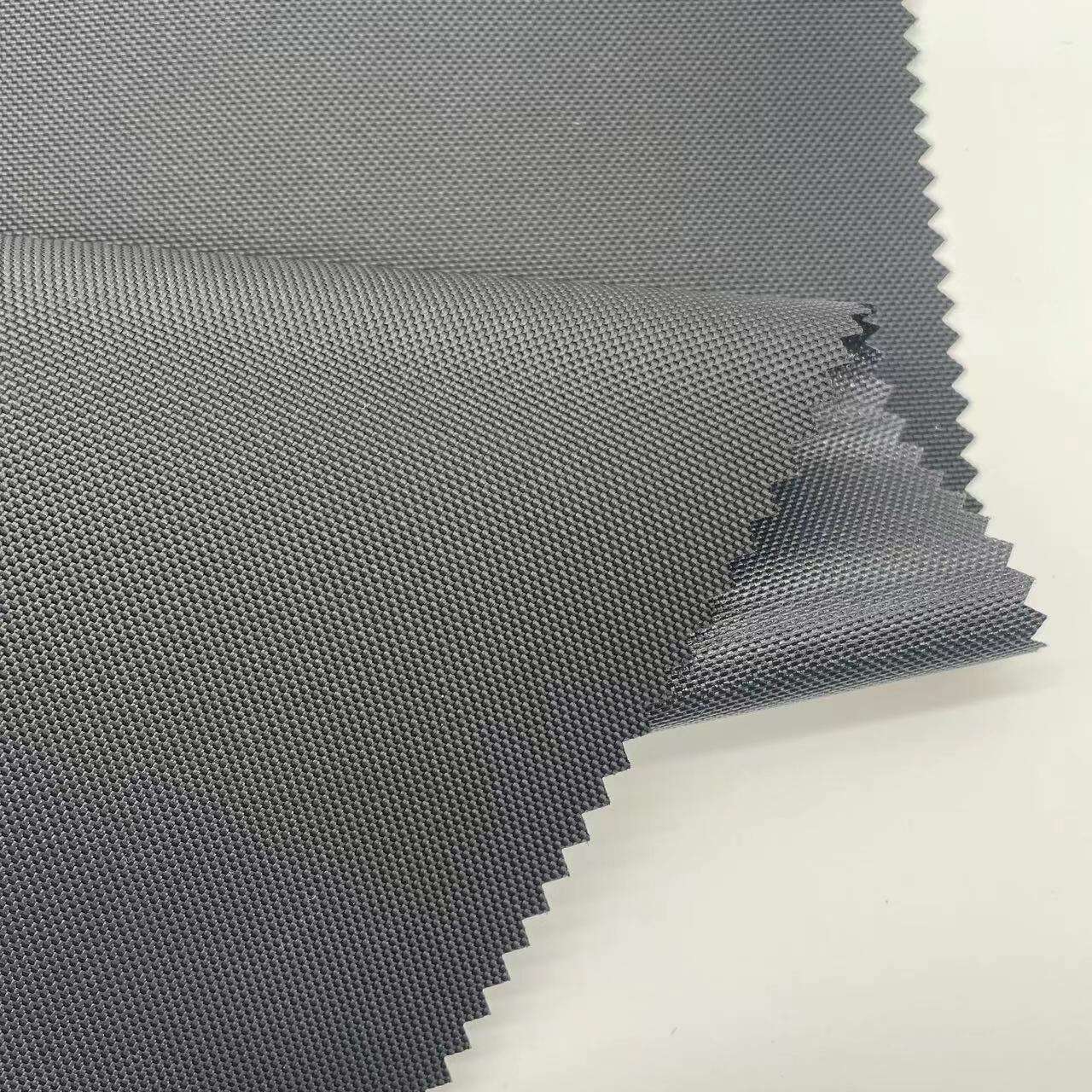

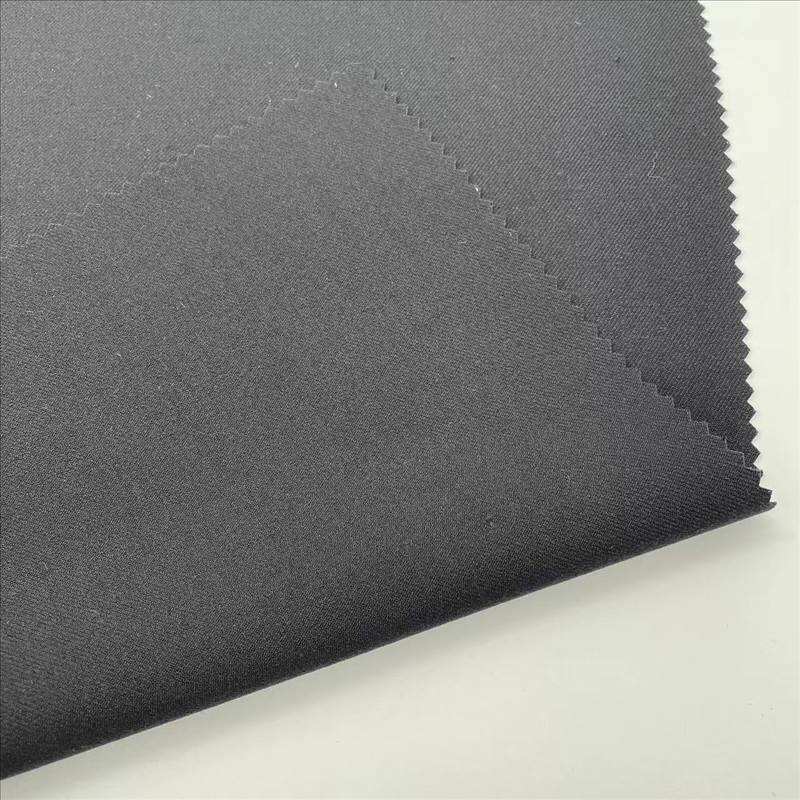

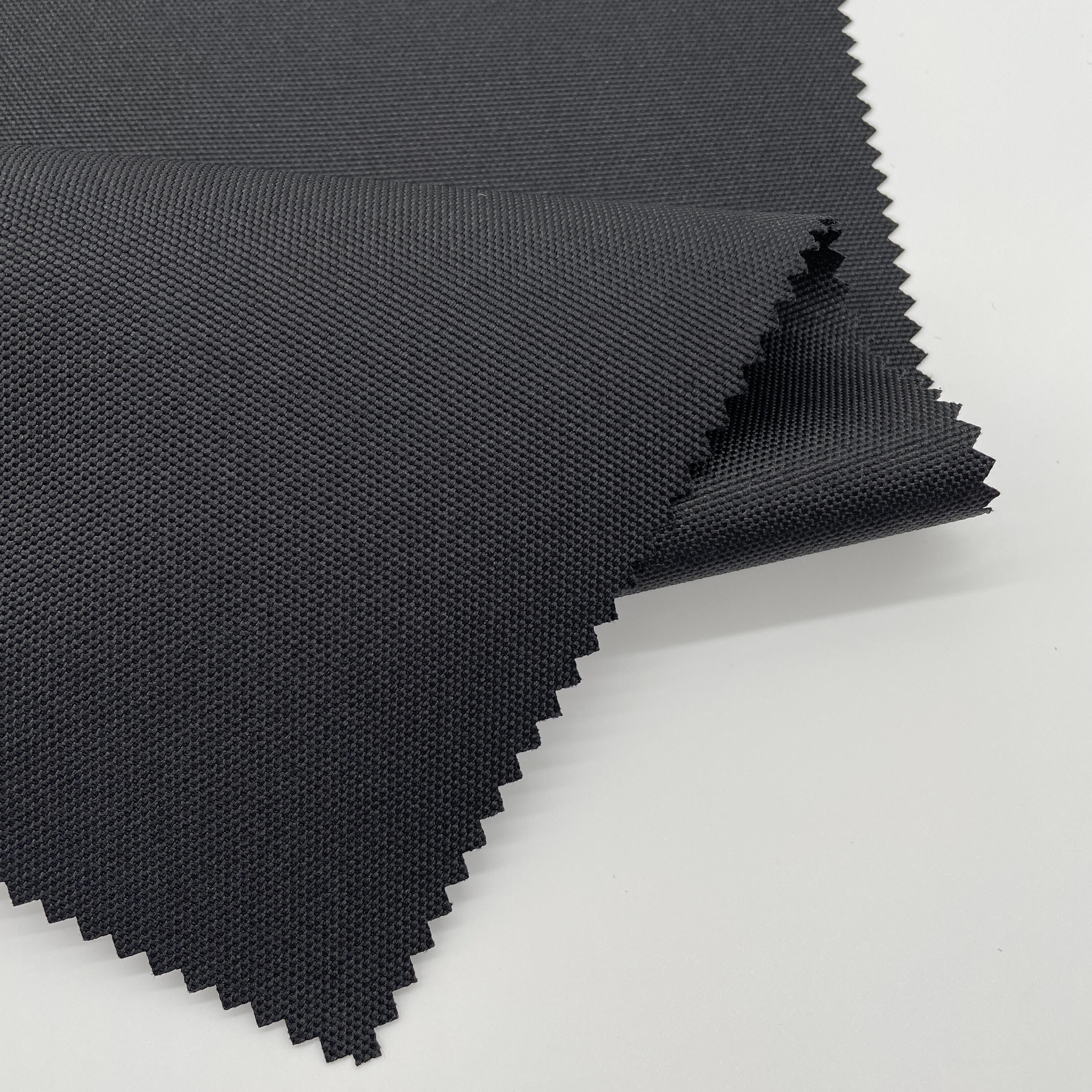

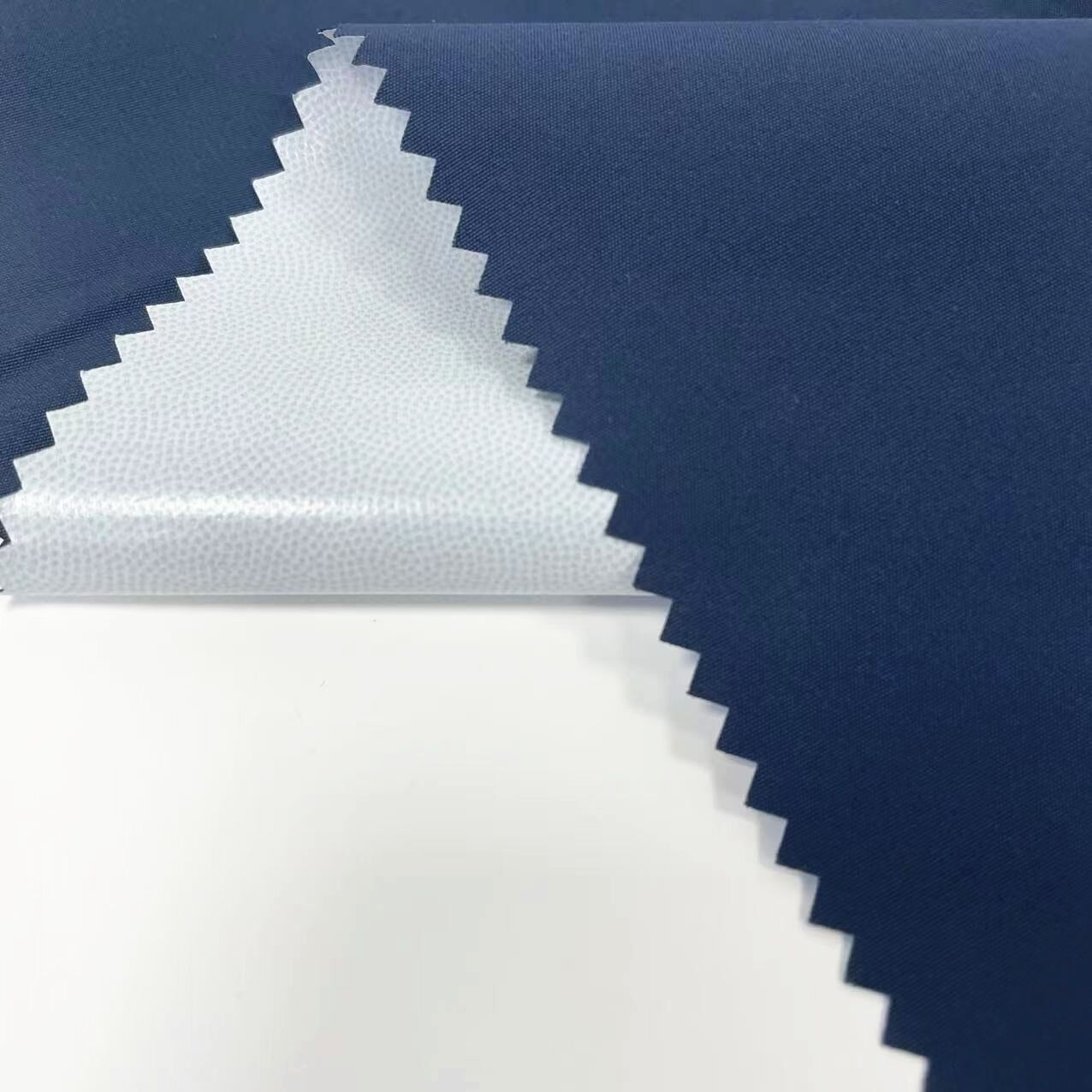

NFPA 701 flame retardant PU coated HT polyester 840D high tenacity rip-stop oxford fabric with durable water repellent

| Content: | Polyester |

| Coating: | PU(Polyurethane) |

| Country of origin: | China |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

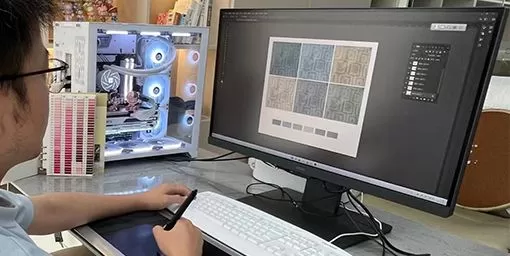

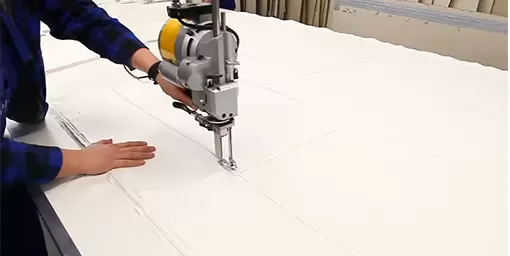

- Process flow

- Related products

- Inquiry

Parameter

Engineered for scenarios where safety and durability are non-negotiable, our NFPA 701 Compliant Flame Retardant 840D High Tenacity Rip-Stop Oxford Fabric represents the pinnacle of protective textile technology. This robust material is specifically designed for demanding applications in public spaces, event production, and military & tactical gear, where its inherent flame-resistant properties provide critical extra seconds for occupant safety and asset protection. The foundation of this fabric is its superior 840D high tenacity rip-stop oxford fabric construction, which integrates a reinforced grid pattern directly into the weave. This ingenious design effectively prevents small tears and punctures from spreading, significantly enhancing the material's lifespan and reliability under stress.

Rigorous Compliance and Verified Performance

Trust is built on verifiable data and adherence to the highest standards. This PU Coated Fabric is not merely treated with flame retardants; it is engineered to meet the stringent requirements of NFPA 701: Standard Methods of Fire Tests for Flame Propagation of Textiles and Films. Each production batch undergoes rigorous in-house and third-party laboratory testing to certify its flame retardancy, in addition to checks for hydrostatic pressure resistance and tear strength. We provide these test reports to our clients, offering full transparency and ensuring the material you receive is certified for your project's safety codes. Our commitment to technical excellence means this 840D high tenacity rip-stop oxford fabric delivers consistent, reliable performance you can count on.

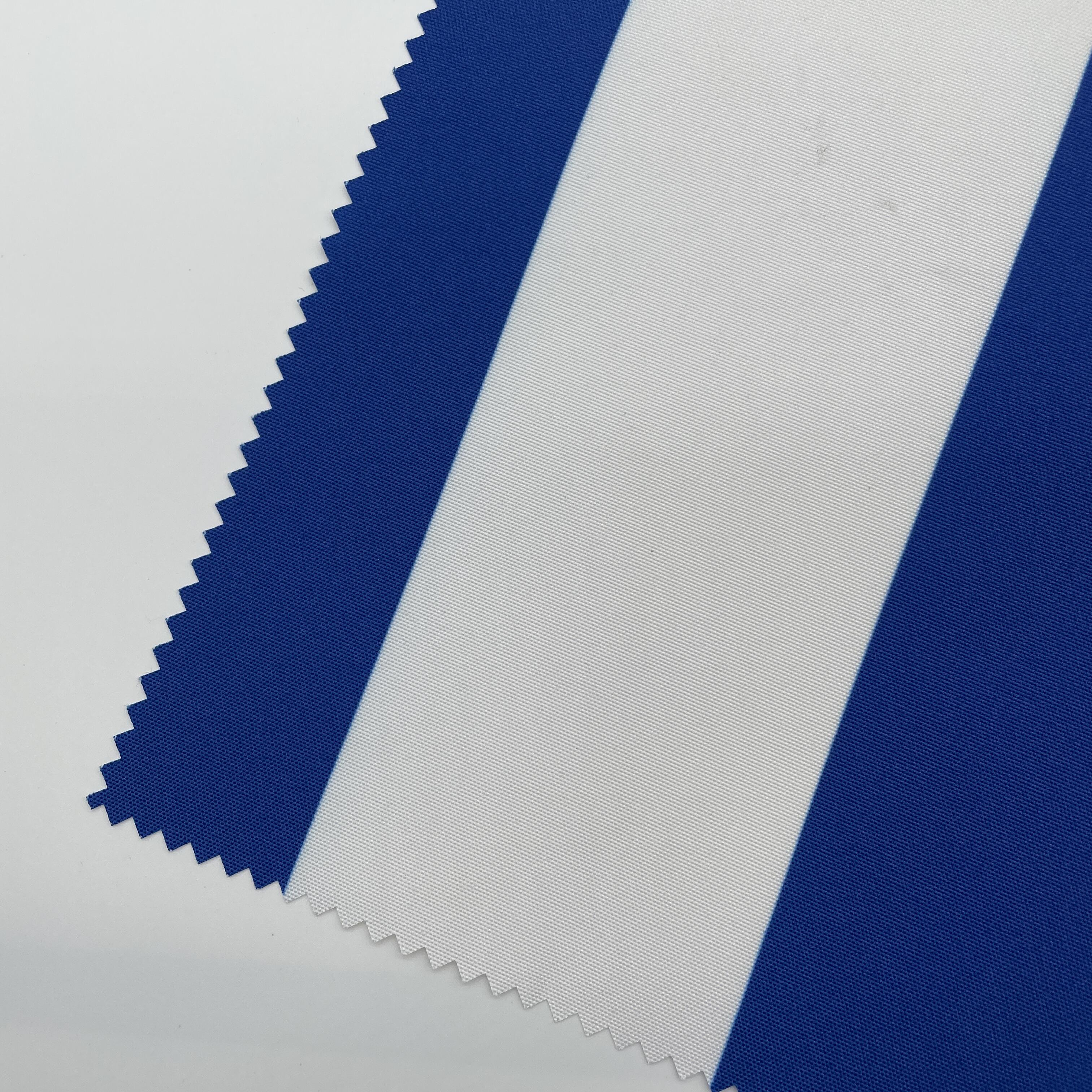

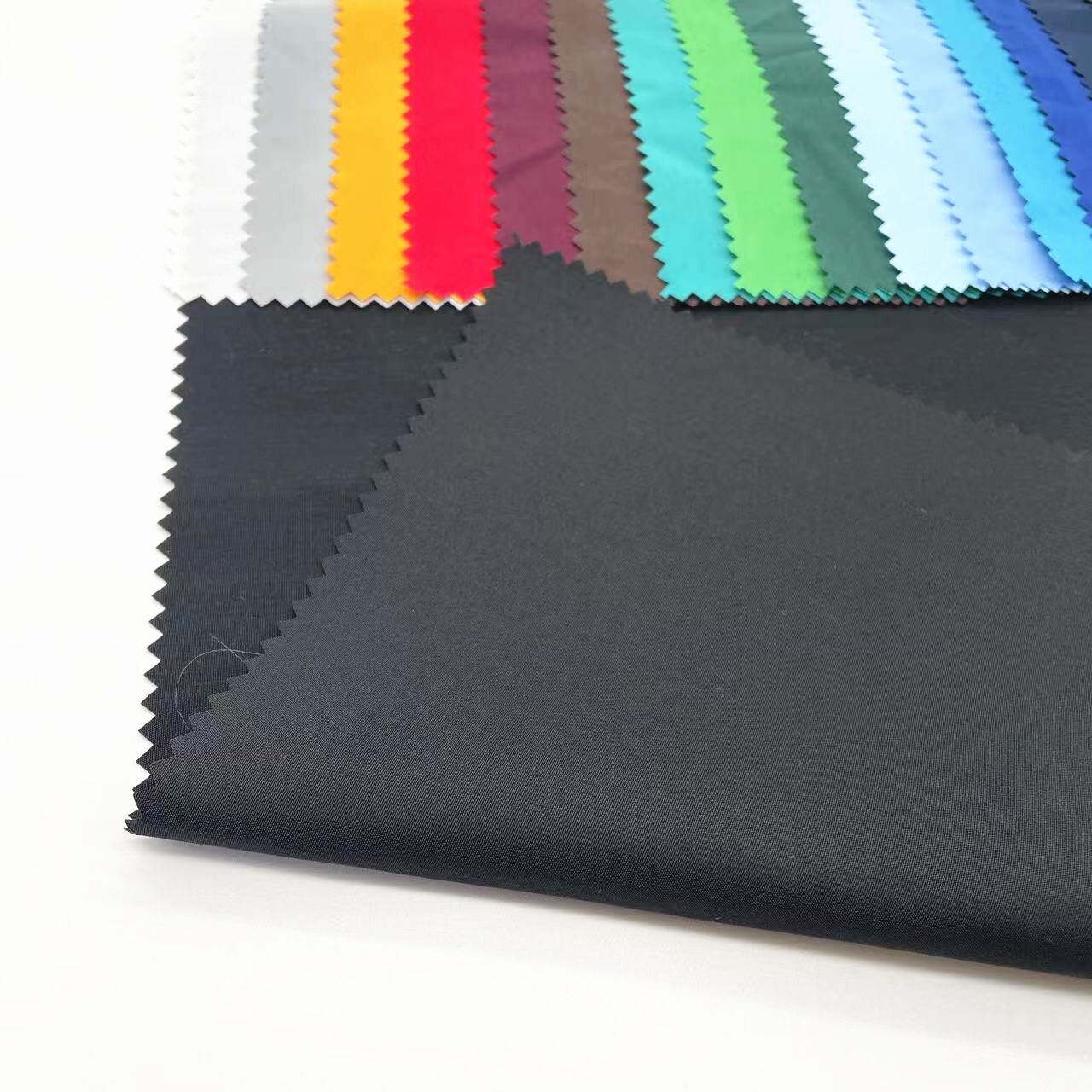

Your Strategic Partner for Custom Safety Solutions

Choosing our fabric means more than purchasing a material; it's gaining a partner dedicated to your operational success. We stand out by offering true flexibility, including a practical Low Minimum Order Quantity (MOQ) of 1000 meters. This allows you to manage inventory efficiently for specialized projects, prototype new safety gear, or fulfill custom contracts without a massive upfront investment. Our streamlined service流程 (service process) is designed for precision, guiding you from the initial technical consultation and sample approval stage to seamless logistics and delivery. We collaborate with you to ensure the fabric's specifications—such as the durable water repellent (DWR) finish and PU coating level—are perfectly tailored to your end-use.

In conclusion, this NFPA 701 Compliant 840D high tenacity rip-stop oxford fabric is more than just a durable textile; it is an integrated safety solution. It combines mechanical strength with certified fire resistance to protect both people and property. By selecting this fabric, you are investing in a product backed by a supplier that prioritizes technical integrity, customer collaboration, and flexible manufacturing to meet the highest standards of performance and safety.

Applications:

Our NFPA 701 Compliant Flame Retardant 840D High Tenacity Rip-Stop Oxford Fabric is engineered for environments where failure is not an option. Its unique combination of certified fire resistance, exceptional tear strength, and durable weather protection makes it the definitive choice for a wide range of critical, commercial, and tactical applications.

Public Venue & Event Safety

The primary application for this advanced fabric is in public spaces and large-scale events where fire safety codes are paramount. It is the ideal material for constructing temporary structures such as exhibition stand coverings, stage backdrops, and partitioning curtains. Its NFPA 701 certification ensures compliance with strict fire codes, providing crucial protection for crowded venues. Furthermore, the inherent durability of this 840D high tenacity rip-stop oxford fabric makes it perfect for heavy-duty event essentials like protective equipment covers, VIP enclosure walls, and high-traffic flooring, where its rip-stop weave resists damage from constant setup and teardown.

Military, Tactical & Emergency Services Gear

In mission-critical scenarios, gear must perform under extreme duress. This fabric is specified for a wide array of tactical equipment, including protective gear bags, field deployable shelters, and camouflage netting. The high tenacity yarns provide exceptional resistance to abrasion and tearing when exposed to rough terrain and rigorous use. The flame-retardant properties add a vital layer of safety for equipment stored near vehicles or in field operations involving pyrotechnics or potential fire hazards. The durable water repellent (DWR) finish ensures that essential equipment remains dry and operational in adverse weather conditions.

Industrial & High-Value Logistics

Beyond personnel safety, this fabric is deployed for protecting valuable assets in high-risk industrial settings. It is used for welding station screens, machinery covers in manufacturing plants, and protective tarps in the oil and gas industry—areas where sparks and heat are ever-present risks. The robust 840D high tenacity rip-stop oxford fabric construction is also ideal for specialized logistics, such as custom-designed covers for sensitive military hardware, flight line equipment, and other high-value cargo requiring superior abrasion resistance and a verified flame-retardant barrier during transport and storage.

In essence, this fabric serves sectors where material performance is directly linked to safety, security, and operational integrity. From ensuring public welfare at a concert to protecting a soldier's equipment in the field, our NFPA 701 Compliant 840D Oxford Fabric delivers a trusted, multi-functional solution built to meet the most demanding specifications.

Specifications:

| Yarn: | 840D*840D | ISO 7211/5 |

| Composition: | 100%Polyester | ASTM D629 |

| Weave: | plain | Visual |

| Density(in): | W54*F33 | ISO 7211/2 |

| Finishing: | DWR+PU coating | Visual |

| Thickness: | 0.55MM | ASTM D 1777 |

| Width: | 350 | ASTM D 3774 |

| Weight: | 280GSM | ASTM D 3776 |

| Spray rating: | 95% | AATCC TM22 |

| Tear strength: | 387.4 | ASTM D2261 |

| Tensile strength 1'': | W:471.2LBF, F:199LBF | ASTM D5034-21 Grab test |

| Flame retardant: | PAss | NFPA701 |

| Hydrostatic Pressure: | 2000MM | AATCC TM127 |

Competitive Advantage:

High Quality

Factory direct sell price

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ