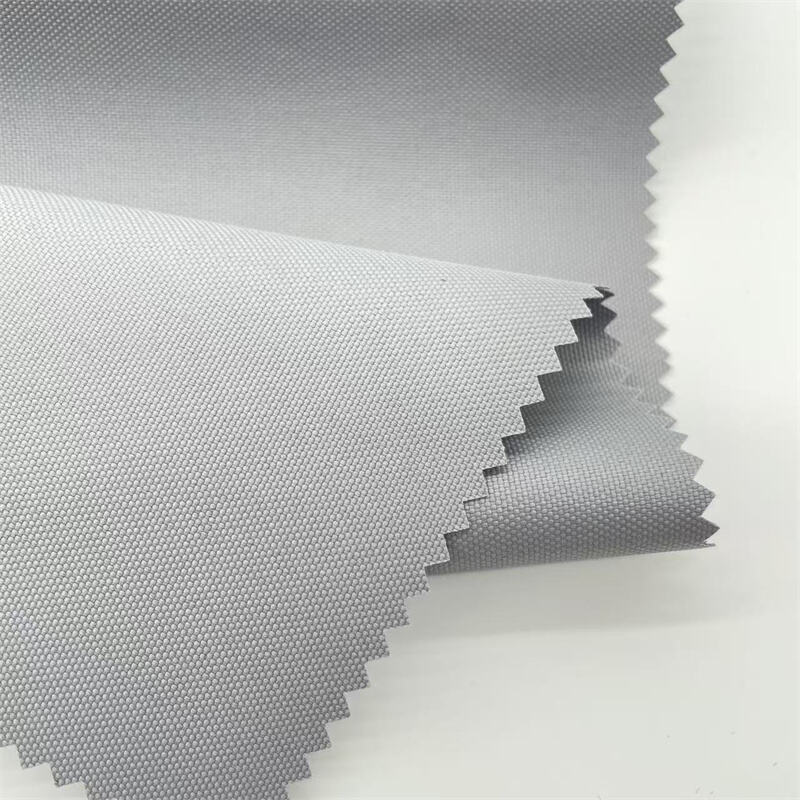

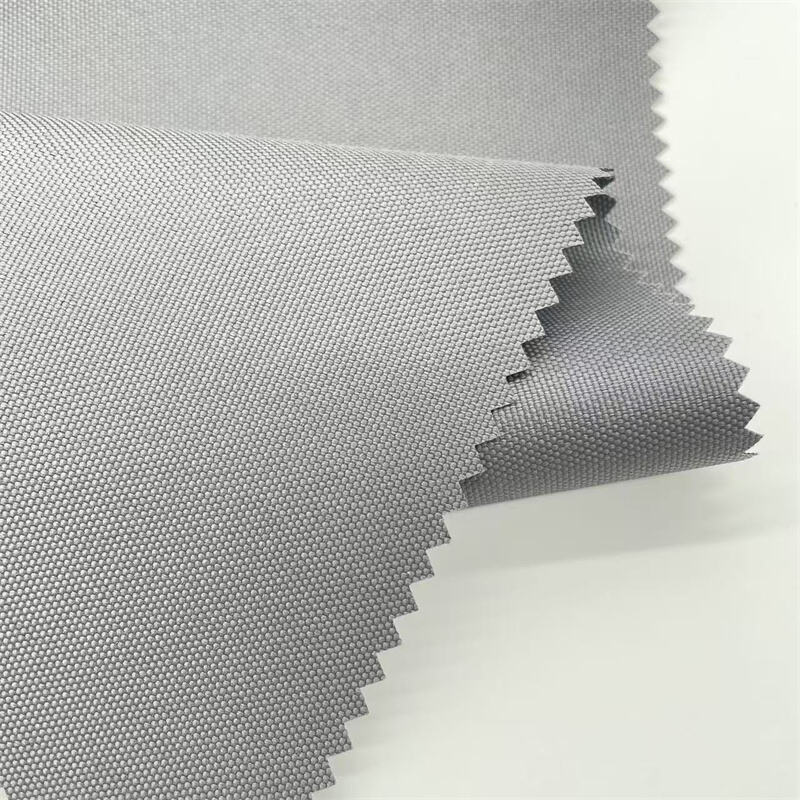

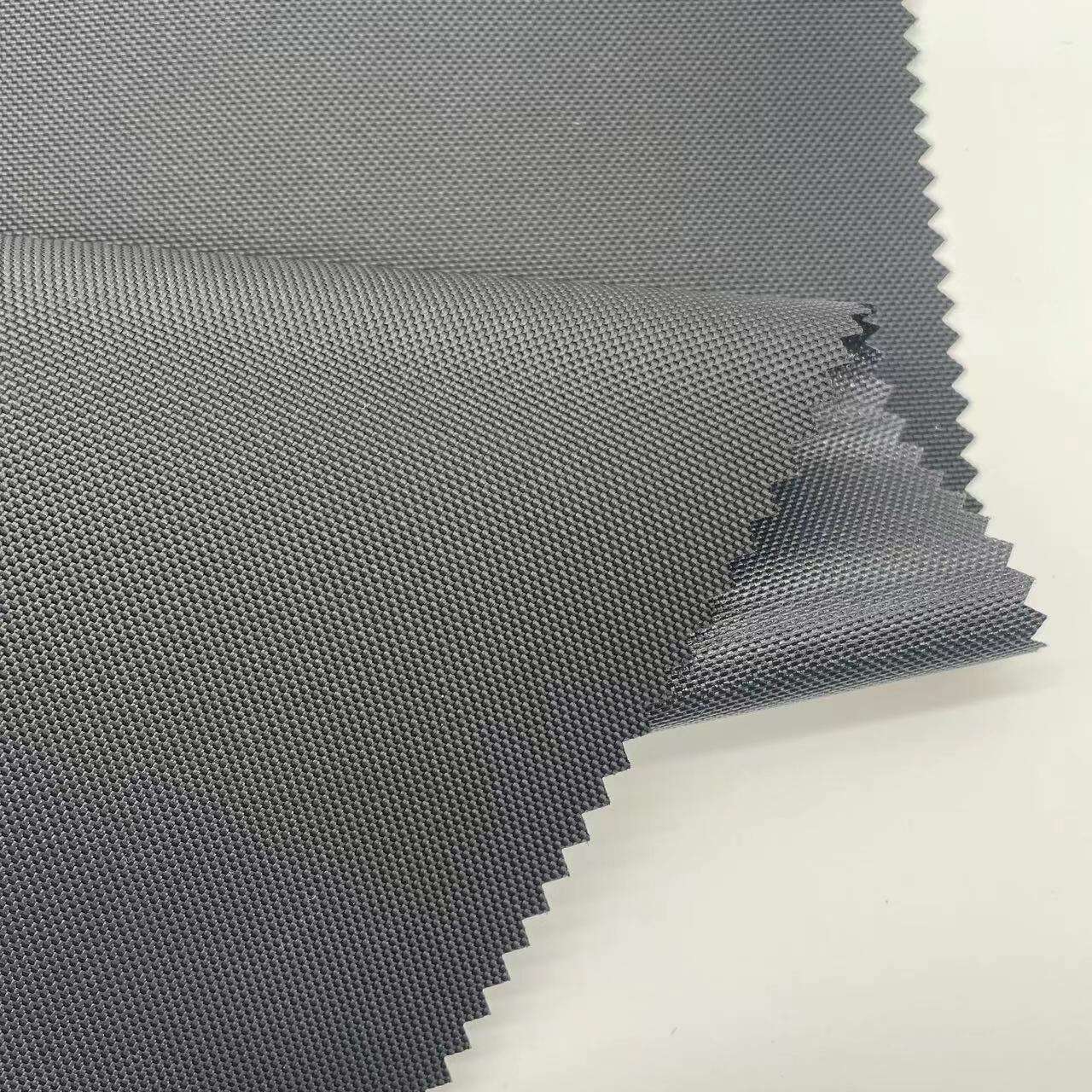

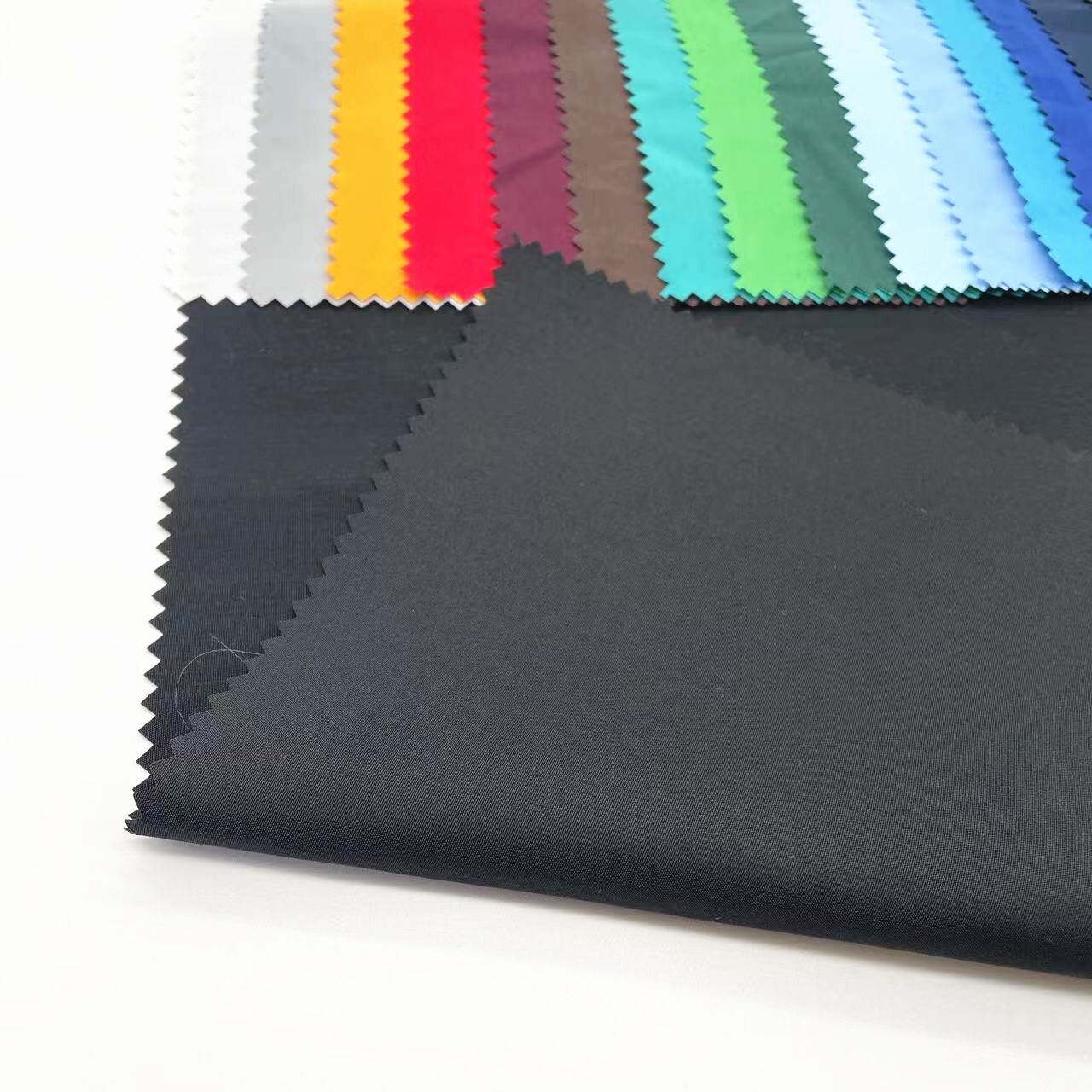

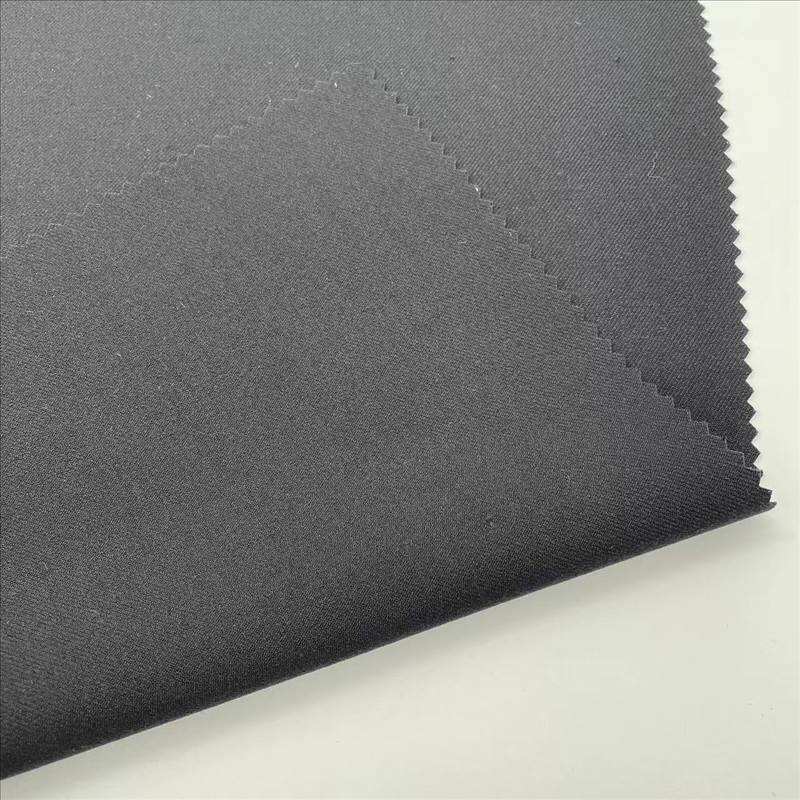

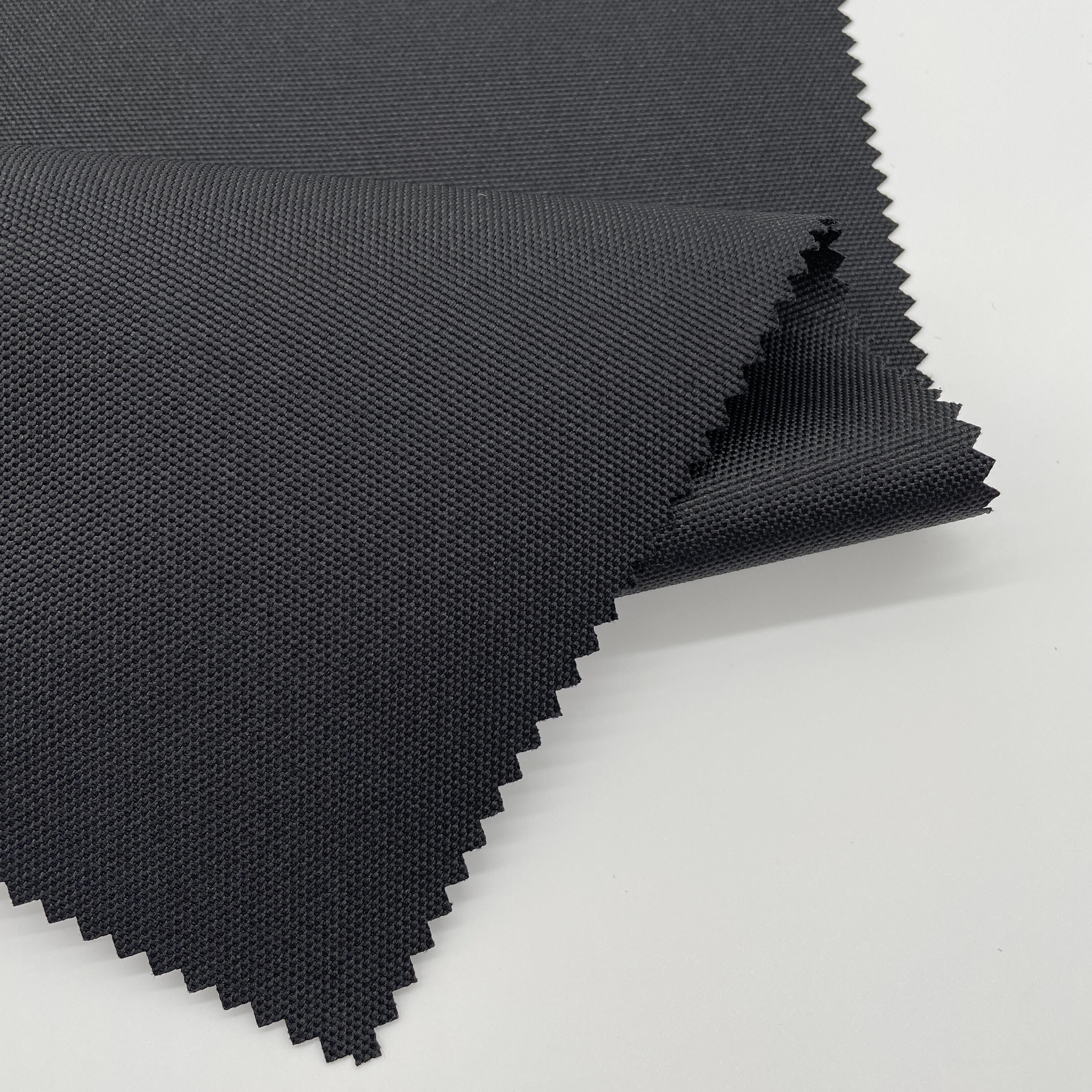

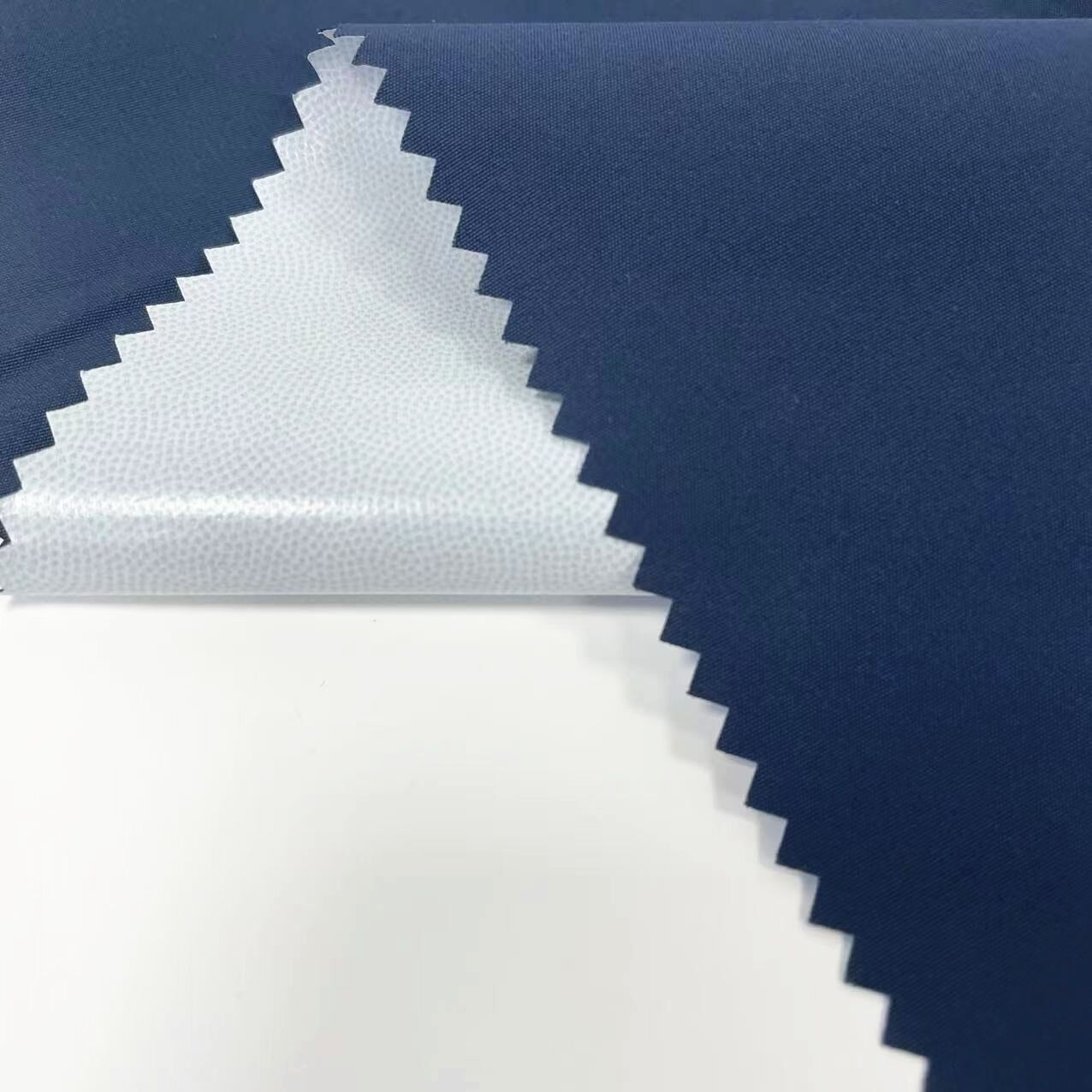

600D Solution Dyed Polyester Fabric PU Coated Fabric For Boat Cover Awning

| Content: | Polyester |

| Coating: | PU(Polyurethane) |

| Country of origin: | China |

| Weaving: | Plain |

| Minimum Order Quantity: | 1000Yards |

| Available coatings: | PU/PVC/TPE/TPU/ULY |

| Packaging Details: | 50yards/roll |

| Delivery Time: | 20-25days after receiving deposit |

| Payment Terms: | 30% T/T in advance, 70% against copy of B/L |

| Supply Type: | Make to order |

- Parameter

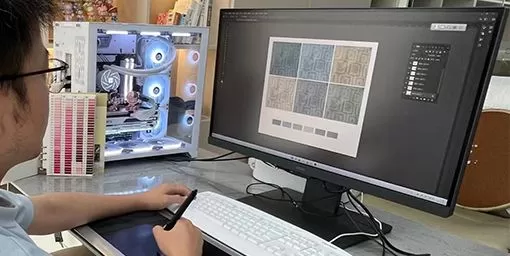

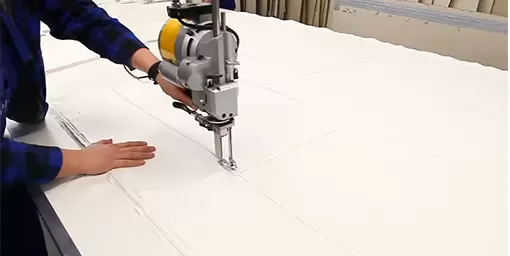

- Process flow

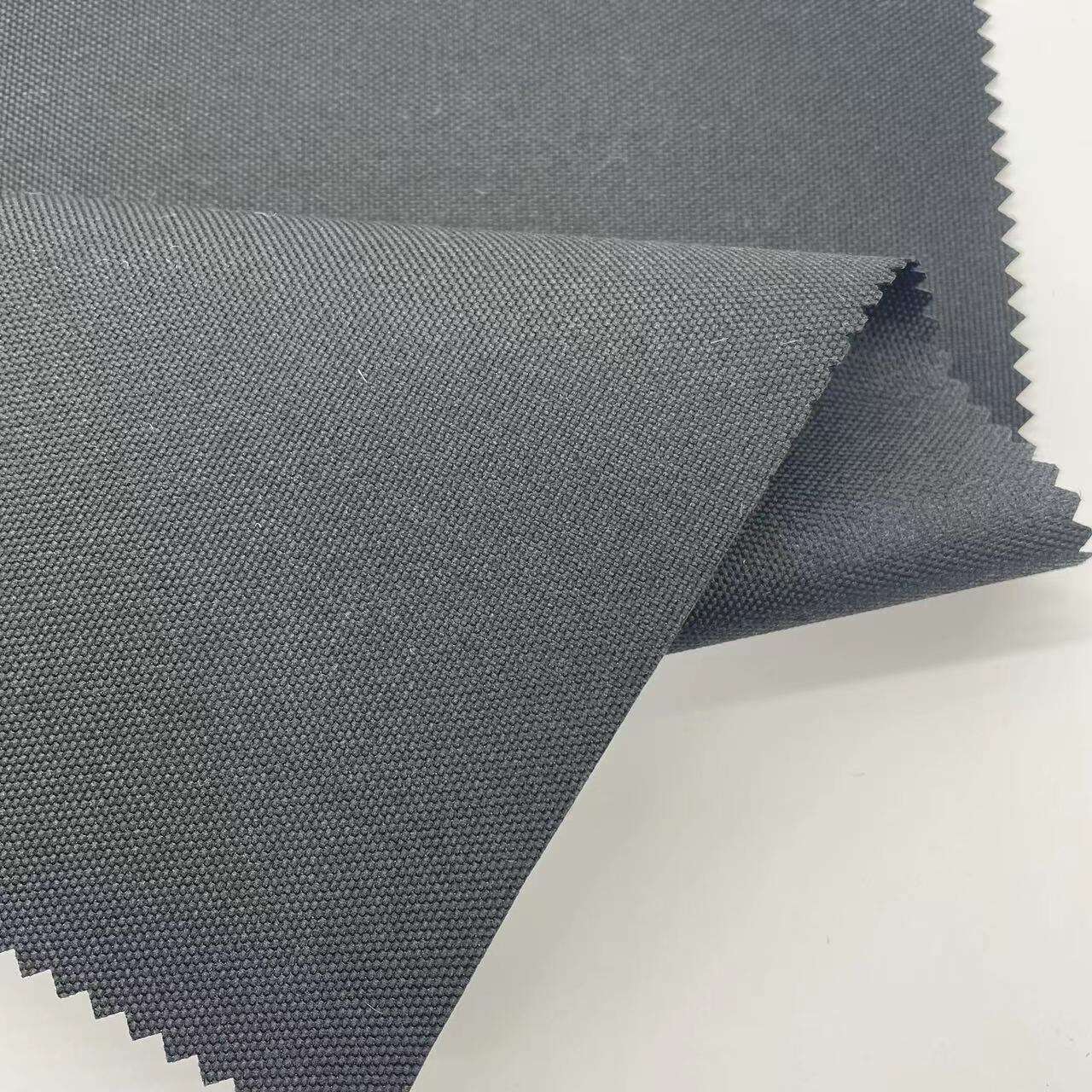

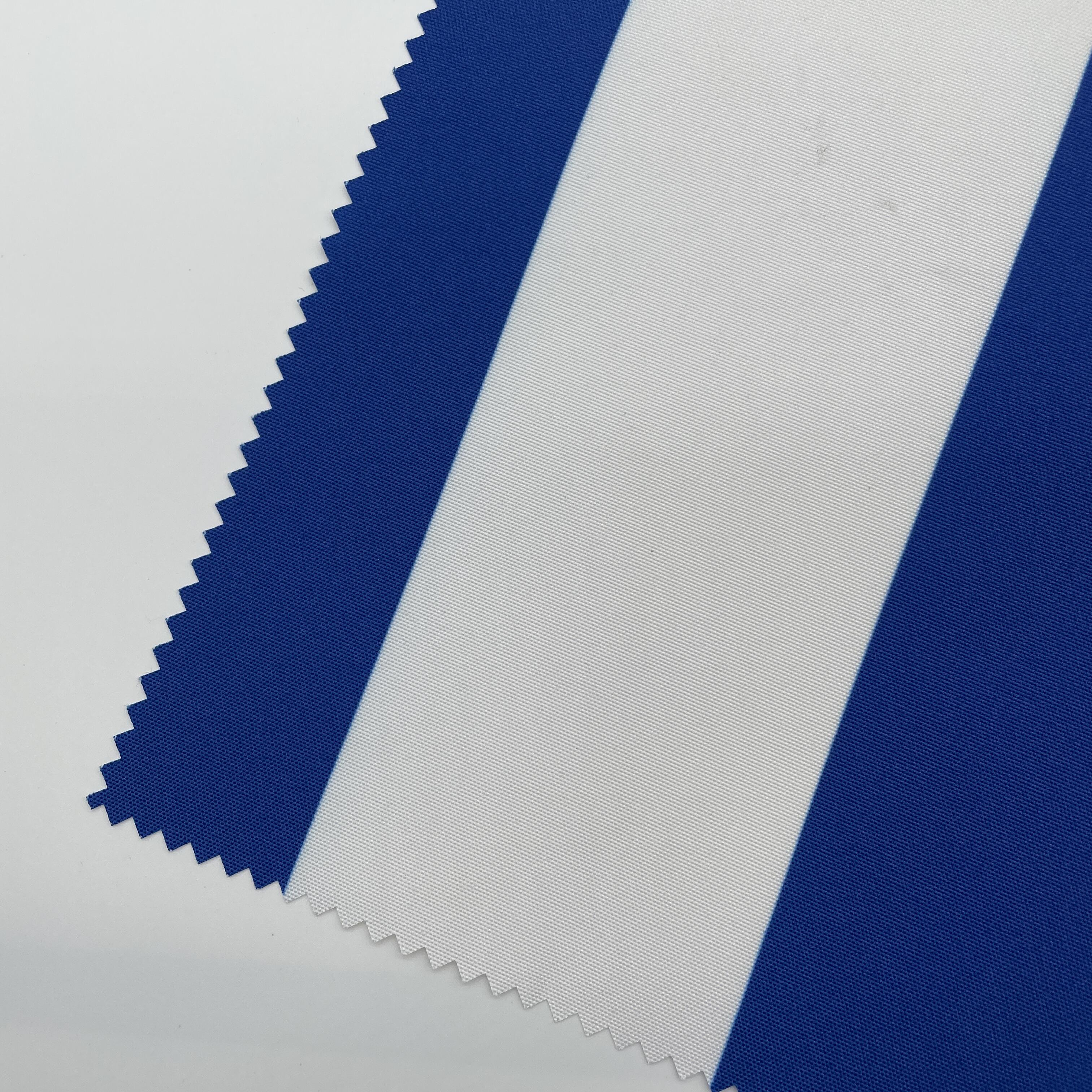

- Related products

- Inquiry

Parameter

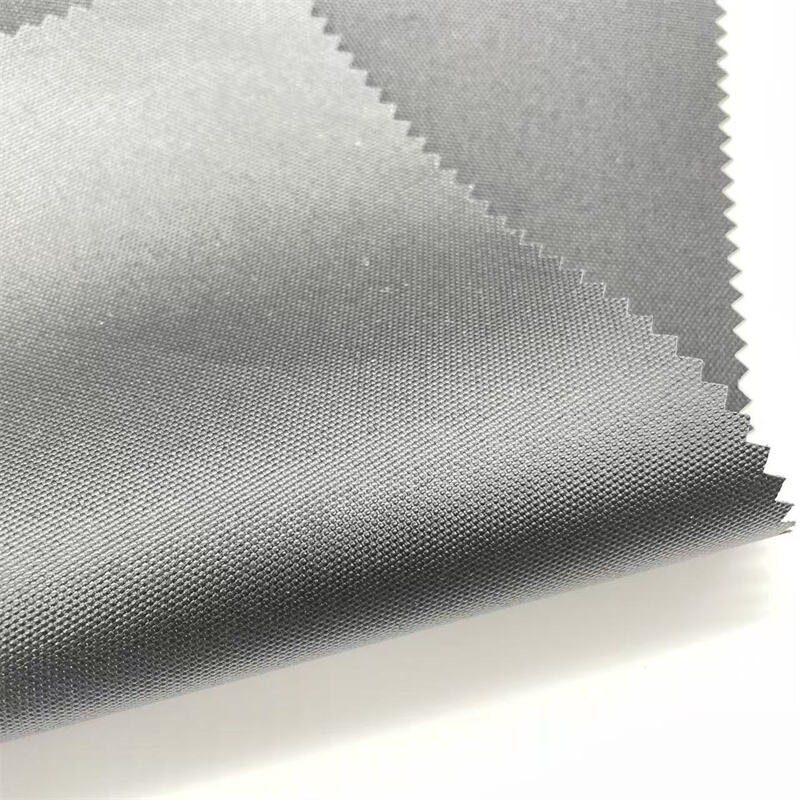

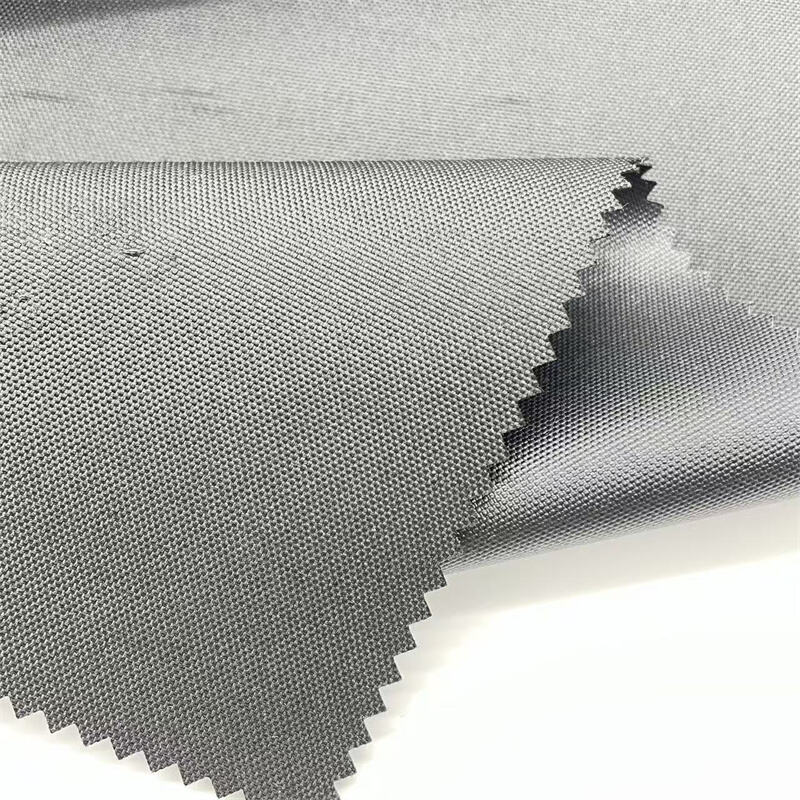

Discover the next generation of marine and awning protection with our premium 600D Solution Dyed Polyester Fabric. This high-performance material is engineered from the ground up to defy the harsh elements, offering unparalleled durability and long-lasting beauty for your boat covers, awnings, and outdoor enclosures. Unlike standard coated fabrics, our solution begins at the fiber level. The innovative solution dyeing process ensures that the rich, vibrant color is embedded directly into the polyester yarns, making it resistant to fading from prolonged UV exposure. This foundational strength is then enhanced with a uniform Polyurethane (PU) coating, creating a robust, waterproof, and flexible shield that stands up to sun, rain, and salt.

Our Commitment to Quality and Your Assurance

We understand that a product is only as good as the process behind it. Our PU Coated Fabric undergoes a rigorous multi-stage quality control process. Every batch is tested for key performance metrics, including hydrostatic head resistance (exceeding 3000mm), tear strength, and UV stability. We provide detailed test reports and material certifications upon request, giving you complete transparency and confidence in the specifications of the material you are purchasing. Our technical team works closely with international standards to ensure our 600D Solution Dyed Polyester Fabric consistently meets the high demands of the marine and outdoor industries.

Why Choose Our Fabric Over Alternatives?

Choosing us means more than just buying a material; it's partnering with a supplier dedicated to your success. We offer the unique advantage of flexible customization with a low Minimum Order Quantity (MOQ) of just 1000 meters, allowing you to prototype new designs or fulfill specialized projects without massive inventory commitments. Our customer-centric service流程 (service process) is designed for a seamless experience, from your initial technical inquiry and sample request to final delivery and after-sales support. We guide you through fabric selection, provide cutting guidance, and ensure your order is processed efficiently.

Ultimately, our 600D Solution Dyed Polyester Fabric represents a perfect synergy of advanced material science and practical application. It delivers the resilience needed for demanding marine environments while maintaining the aesthetic appeal required for modern awnings. When you select this fabric, you are investing in a solution that protects your assets and enhances your brand reputation. Trust in a material built to last, backed by a company committed to quality and service.

Applications:

Engineered for extreme durability and all-weather resistance, our 600D Solution Dyed Polyester Fabric is the material of choice for a wide range of demanding applications across multiple industries. Its unique combination of strength, flexibility, and colorfastness makes it an ideal solution wherever reliable protection is paramount.

Marine & Outdoor Protection

The primary and most demanding application for this high-performance PU Coated Fabric is in the marine industry. It is expertly crafted into durable boat covers, sail covers, and bimini tops that shield valuable vessels from harsh UV rays, saltwater corrosion, and torrential rain. Beyond the docks, this fabric is equally effective for commercial and residential awnings, patio furniture covers, and gazebo enclosures. The solution-dyed yarns guarantee that canopies and shades retain their vibrant color season after season, maintaining aesthetic appeal without becoming brittle or faded. This makes our 600D Solution Dyed Polyester Fabric a cornerstone for long-lasting outdoor infrastructure.

Commercial, Agricultural & Transport Solutions

The robustness of this material extends into heavy-duty commercial uses. It is widely employed in the creation of protective tarpaulins for construction sites, as liners for temporary shelters, and as covers for agricultural equipment and hay bales, protecting them from moisture and sun damage. In the logistics sector, its high tear strength makes it perfect for truck side curtains and cargo covers, ensuring goods remain secure and dry during transit. The fabric's lightweight yet tough nature provides a reliable barrier against the elements in these rigorous environments.

Specialized Custom Projects & Niche Markets

The flexibility of our manufacturing process allows this versatile fabric to be tailored for specialized projects. Its excellent printability (on the coated side) and resistance to mildew make it a suitable candidate for outdoor promotional banners, event tents, and temporary exhibition structures. Furthermore, its reliable waterproof qualities are utilized for lightweight utility covers for recreational vehicles (RVs), outdoor machinery, and as groundsheets for camping. The ability to offer custom widths, colors, and coatings with a low MOQ empowers designers and manufacturers to innovate, using this 600D Solution Dyed Polyester Fabric as a foundational material for new and unique products that require a proven, dependable substrate.

In essence, wherever there is a need for a strong, waterproof, and colorfast material that can endure prolonged exposure to the elements, our 600D Solution Dyed Polyester PU Coated Fabric provides a trusted and high-performing solution.

Specifications:

| Designation | Norm | Test value | Unit |

| Fabric name | 100%Solution dyed polyester fabric | ||

| Description | Surface waterproof/PU-coating | ||

| Texture | Plain/Woven | ||

| Meterial composition | (EU)No1007/2011 | 95%Polyester5%PU | 600D*600D 76T |

| Width | EN 1773 | 61/62'' | inch |

| Weight | EN 12127 | 6.8 235 | oz/yd² g/m² |

| Thickness | ISO 5084 | 150.35 | milmm |

| Hydrostatic Pressure | EN 20811 | >8000>800 | pamm |

| Weter repellency | AATCC 22EN ISO 4920 | >90 | Grade |

| Mold resistance | AATCC 30-2017 | Grade 1 | 7 Days |

| Weather resistance | ISO 105-B04 | 7-8 | Grade |

| Colour fastness to light | AATCC16-3ISO 105-B02 | 500-720Hours:4 | Hour/grade Grade |

| Colour fastness to rubbing | ISO 105-X12 | 4-5 | Grade |

| Colour fastness to migration | ISO 105-x10 | 4-5 | Grade |

| Chlorine resistance | ISO 105-E03 | 4-5 | Grade |

| UV resistance | EN 13758-1 | UPF 50+ | |

| Tearing Strength | ASTM D2261-13 | >16.9Warp | Lbf |

| >12.8Weft | Lbf | ||

| Tensile Strength | ASTM D5034-2019 | >460Warp | Lbf |

| >310Weft | Lbf | ||

| Abrasion Resistance | ASTM D4966-22 | 50000 | Rubs |

Competitive Advantage:

High Quality

Factory direct sell price

Durable water repellent

Excellent color fastness

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ